Magnetic lead screw type axial eddy current damper

An eddy current damper and eddy current damping technology, which is applied in the directions of magnetic springs, springs/shock absorbers, springs, etc., can solve problems such as fading and blocking lubricating oil effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

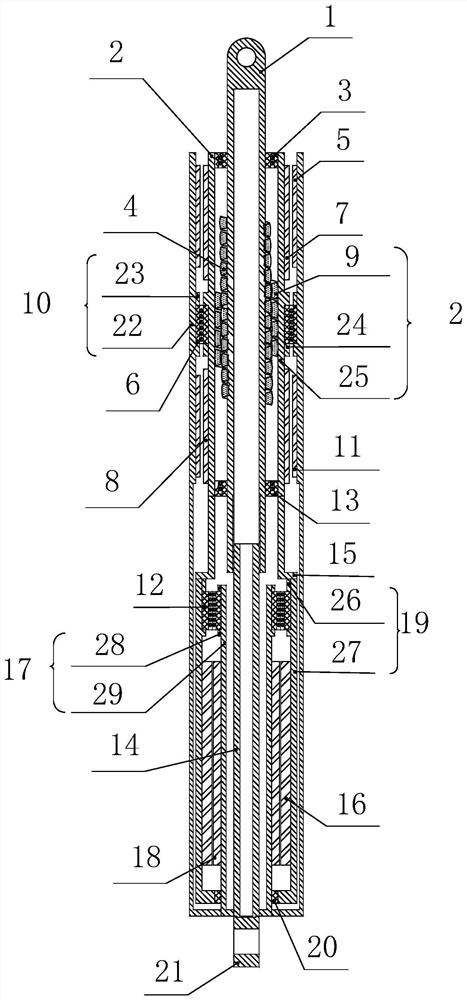

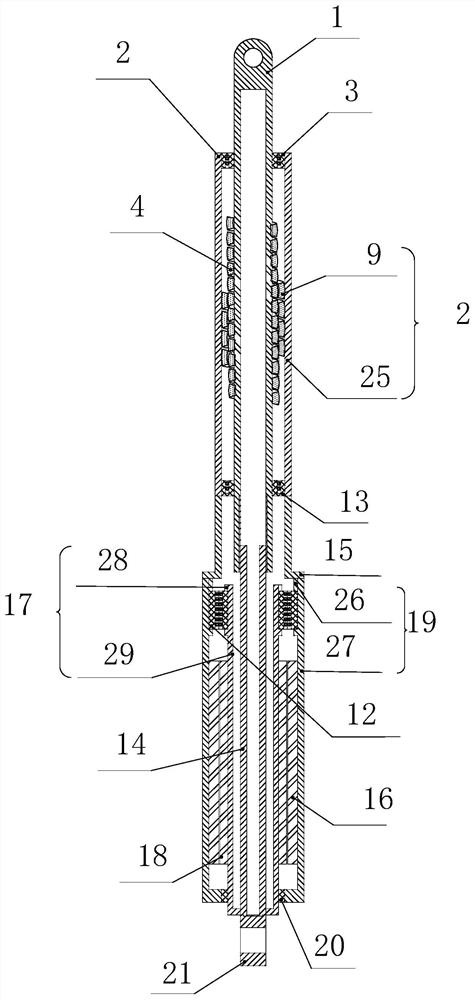

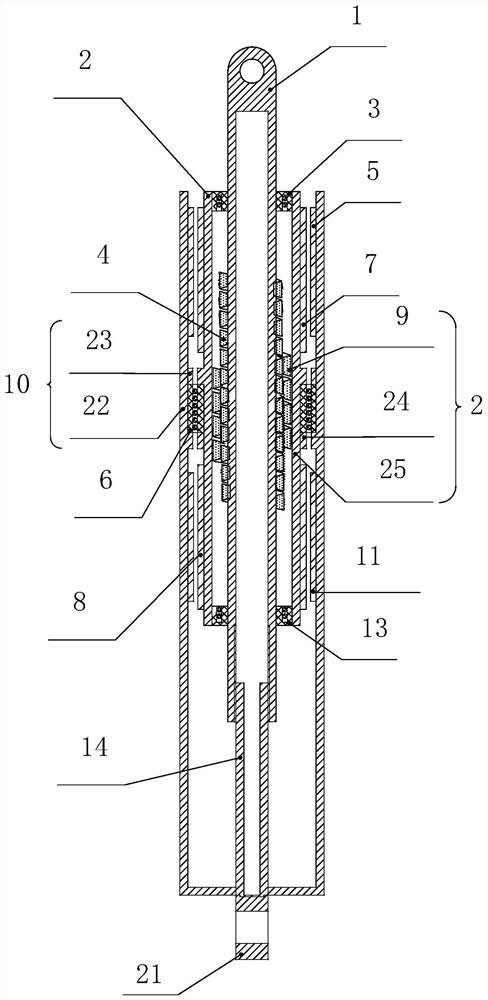

[0049] Such as Figure 1-Figure 3 As shown, a magnetic screw type eddy current axial damper according to the present invention includes:

[0050] A magnetic screw 1 and a magnetic nut 2 adapted thereto;

[0051] The inner guide pipe 14 made of steel or other materials is arranged on the inner side of the steel pipe used for the magnetic screw 1, and an oil-free bushing is arranged between the magnetic screw 1 and the inner guide pipe 14, and the oil-free bush is used for Reduce the friction between the magnetic screw 1 and the inner guide tube 14;

[0052] A connecting nut 15 made of steel or other materials is arranged between the magnetic nut 2 and the inner support tube 17;

[0053] The outer support tube 10 and the inner support tube 17 made of magnetically conductive material can be connected with the end 21;

[0054] End 21 made of steel or other materials;

[0055] A plurality of first magnets 5 and third magnets 11 are provided on the periphery of the magnetic nut ...

Embodiment 2

[0067] Such as Figure 4 Shown, a kind of magnetic screw type electric eddy current axial damper described in the present invention, and embodiment 1 image 3 The difference is that the magnetic nut 2 of the magnetic screw type eddy current axial damper is connected to the outer support tube 10 through the ball bearing one 6 and the ball bearing four 31; the magnetic screw 1 is connected to the magnetic nut through the screw bearing one 3 2 are connected, the magnetic screw rod 1 is connected to the outer support tube 10 through the screw bearing three 30, the outer support tube bearing sleeve two 32, and the outer support tube bearing sleeve three 33 are all connected to the inner wall of the outer support tube 10 by threads, so The second magnetic nut bearing sleeve 34 and the third magnetic nut bearing sleeve 35 are all connected to the outer wall of the magnetic nut 2 by threads.

[0068] With this structural setting, when the damper needs to achieve a large stroke but th...

Embodiment 3

[0070] Generally speaking, the structural types among the magnetic screw, magnetic nut and damping device in Embodiment 1 and Embodiment 2 are basically divided into the following types:

[0071] 1. The magnetic screw 1 and the magnetic nut 2 are connected through the screw bearing 1 and the screw bearing 2 13 at both ends of the magnetic nut, and the magnetic nut and the damping device are connected to the connecting nut 15 through the angular contact bearing 6 and the angular contact bearing 12 at the same time. Specific as figure 1 :

[0072] 2. The magnetic screw 1 and the magnetic nut 2 are connected with the screw bearing 1 and the screw bearing 2 13 at both ends of the magnetic nut, and the magnetic nut and the damping device are connected with the connecting nut 15 through at least one angular contact bearing 12, specifically as figure 2 :

[0073] 3. The magnetic screw 1 and the magnetic nut 2 are connected through the screw bearing one 3 and the screw bearing two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com