Meter performance test system

A test system and measuring instrument technology, applied in the direction of instruments, etc., can solve problems such as inaccurate measuring instrument performance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

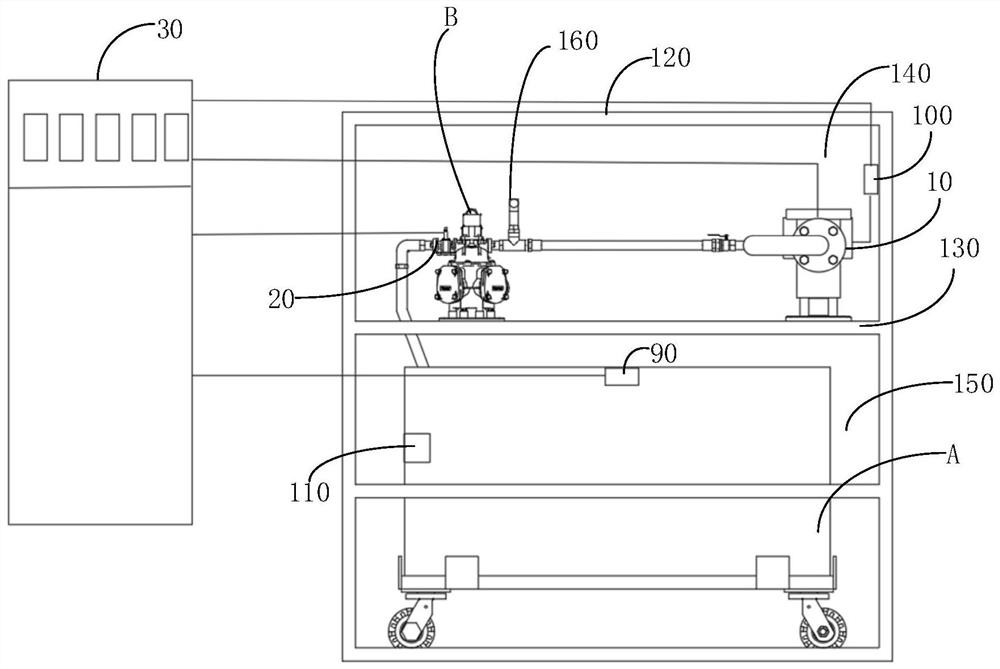

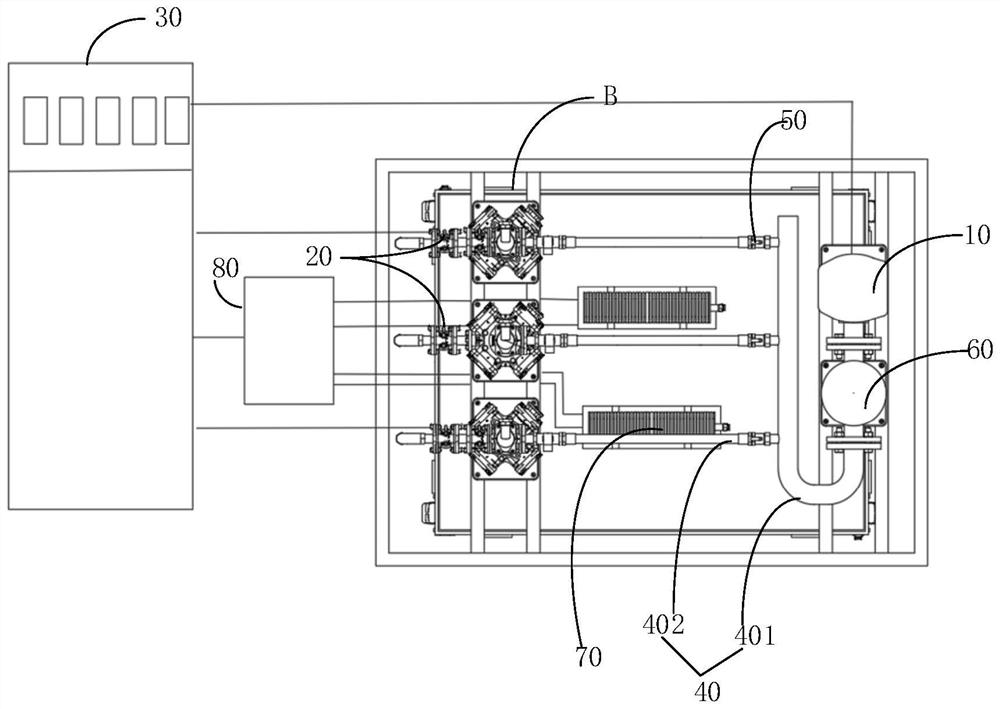

[0022] The embodiment of the present application provides a meter performance testing system, which can simulate the work of the meter, and then evaluate the performance and life of the meter. The system is as follows: figure 1 As shown, it includes an extracting device 10, at least one controllable valve 20 and a control cabinet 30, the inlet of the extracting device 10 is connected to the fuel tank A, and the outlet of the extracting device 10 is connected to the fuel tank A through at least one gauge B to be tested, Wherein, the controllable valve 20 can change the switch state based on the signal sent by the control cabinet 30, that is, open or close according to the signal sent by the control cabinet 30; the number of the controllable valve 20 is the same as the number of the meter B to be teste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com