Printing device for testing liquid performance through delay switching between nozzles and control method of printing device

A printing device and control method technology, applied in printing devices, printing, etc., can solve the problems of small liquid volume range and large limitations, and achieve the effects of wide spray volume range, high applicability, and guaranteed test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

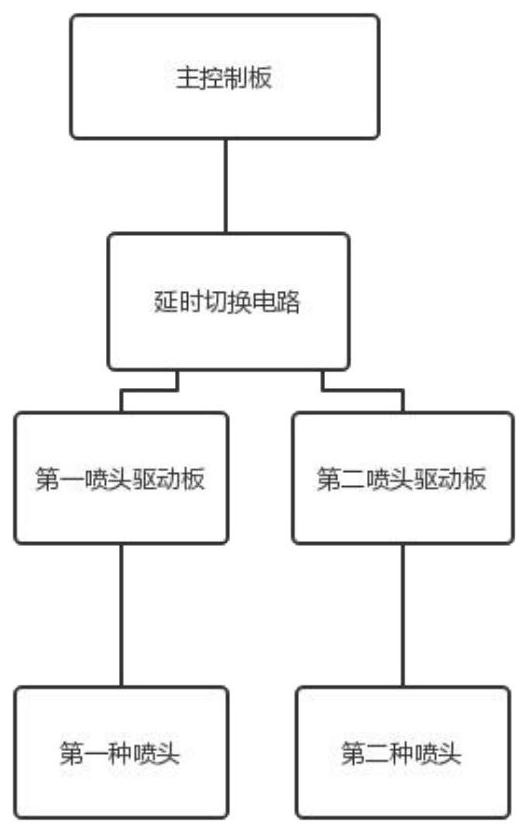

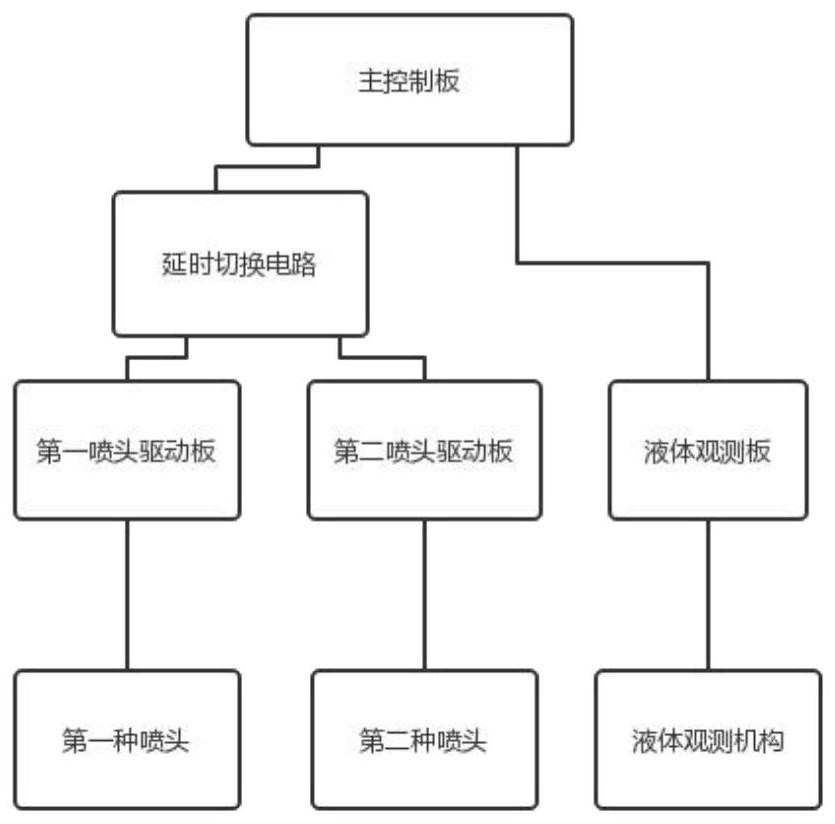

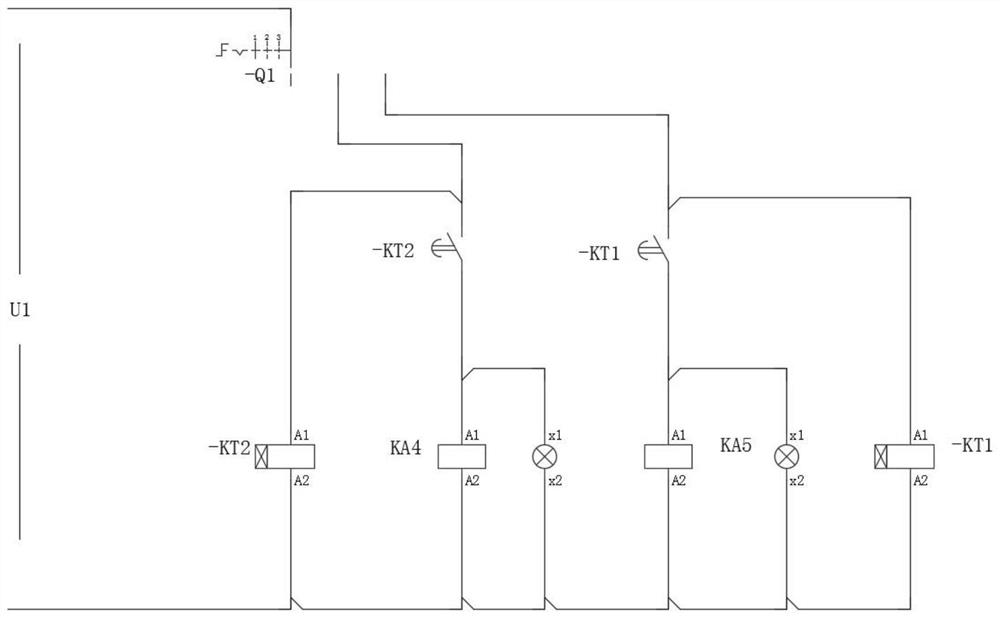

[0039] Embodiment 1 of the present invention provides a printing device for delay switching between nozzles to test liquid performance, which solves the technical problem of instability in the multi-nozzle switching system in the prior art, and is used to switch at least two types of nozzles with different sprayable liquid volume ranges. The nozzle sprays the liquid in a predetermined sequence to test the performance of the liquid, which has the advantages of stably spraying the liquid and accurately testing the performance of the liquid. Wherein, the tested liquid performance includes: at least one of the number of satellite dots of the ink dot, the printing straightness of the ink dot, and the uniformity of the ink dot size. Of course, in order to obtain more accurate liquid performance, other liquid test performances may also be included. For example, fluency, etc., the specific tests that need to be applied are not limited here, and any parameters that can characterize the ...

Embodiment 2

[0104] The second aspect of the present invention provides a control method of a printing device for delay switching between nozzles to test liquid performance; specifically, it is used for controlling the printing device involved in any one of the first embodiment. Specifically, combine figure 1 , the printing device includes: at least two types of nozzles with different sprayable liquid volumes, at least two types of nozzles include: a first type of nozzle 21 and a second type of nozzle 22; a first nozzle driving board corresponding to the first type of nozzle 21; The second nozzle drive board corresponding to the two types of nozzles 22; the main control board; combined Figure 14 , the control method includes: S1. After the main control board controls the first nozzle driving board to drive the first nozzle to spray liquid, control the first nozzle driving board to send a feedback signal to the main control board; S2. After the main control board receives the feedback sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com