Hollow shaft ultrasonic automatic damage judgment method and system

A hollow shaft and ultrasonic technology, which is used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and processing response signals of detection, etc., which can solve the problems of low reliability of detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

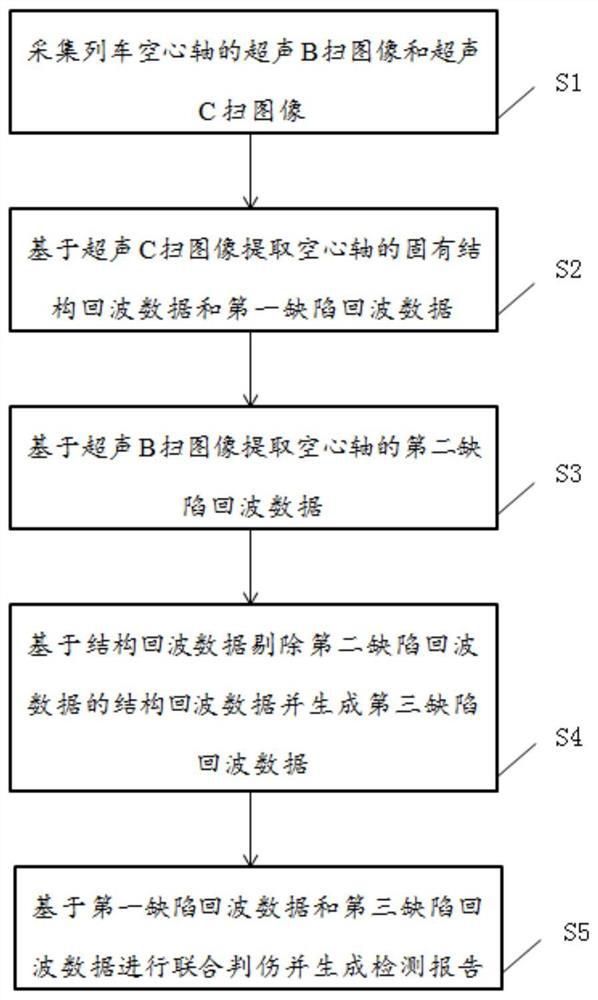

[0019] Such as figure 1 As shown, a hollow shaft ultrasound automatic injury method, including:

[0020] S1: Collect ultrasonic B-scan images and ultrasonic C-scan images of the hollow shaft of the train.

[0021] S2: Extracting intrinsic structure echo data and first defect echo data of the hollow shaft based on the ultrasonic C-scan image.

[0022] Further, the S2 includes: identifying and locating the inherent structural echo contained in the ultrasonic C-scan image by using the echo circumferential trend feature contained in the ultrasonic C-scan channel, generating the inherent structural echo data; extracting the The first defect echo data in the ultrasonic C-scan image. Wherein, the intrinsic structure echo incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com