Train wheel ultrasonic flaw detection method and system

A train wheel and ultrasonic technology, which is applied in the direction of material analysis, image data processing, and detection response signal processing using sound waves/ultrasonic waves/infrasonic waves, which can solve the problems of low reliability of detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

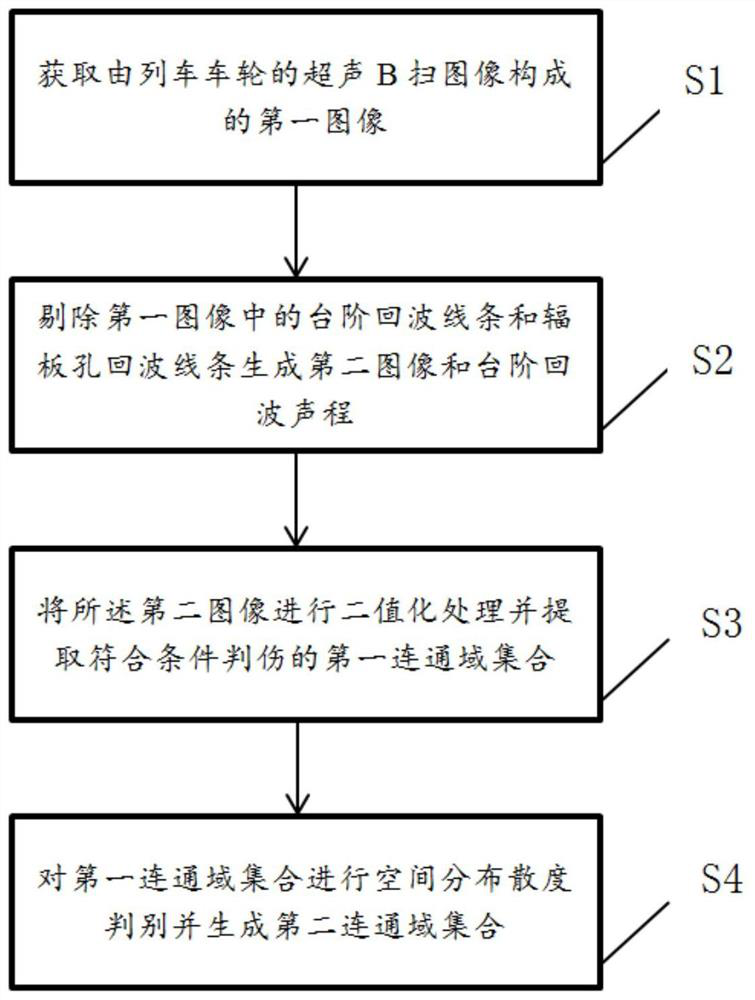

[0021] Such as figure 1 Shown, a kind of train wheel ultrasonic judgment method comprises:

[0022] S1: Acquiring a first image composed of ultrasonic B-scan images of train wheels.

[0023] S2: Eliminate the step echo lines and the web hole echo lines in the first image to generate a second image and a step echo sound path corresponding to the step echo lines.

[0024] Further, since the line of the step echo is a horizontal straight line, the influence of the step echo can be eliminated by performing feature detection on the first image and eliminating the horizontal straight line representing the step echo included in the first image. The step echo sound path corresponding to the horizontal straight line is extracted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com