Breaking-free cast-in-place device for constructional column and using method

A structural column and cast-in-place technology, which is applied to building structures, building components, walls, etc., can solve the problems of increased labor costs and garbage cleaning costs, the inability to fix the pump pipe port, and the inability to use it conveniently, so as to achieve reuse, Increase the cost of garbage cleaning and the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

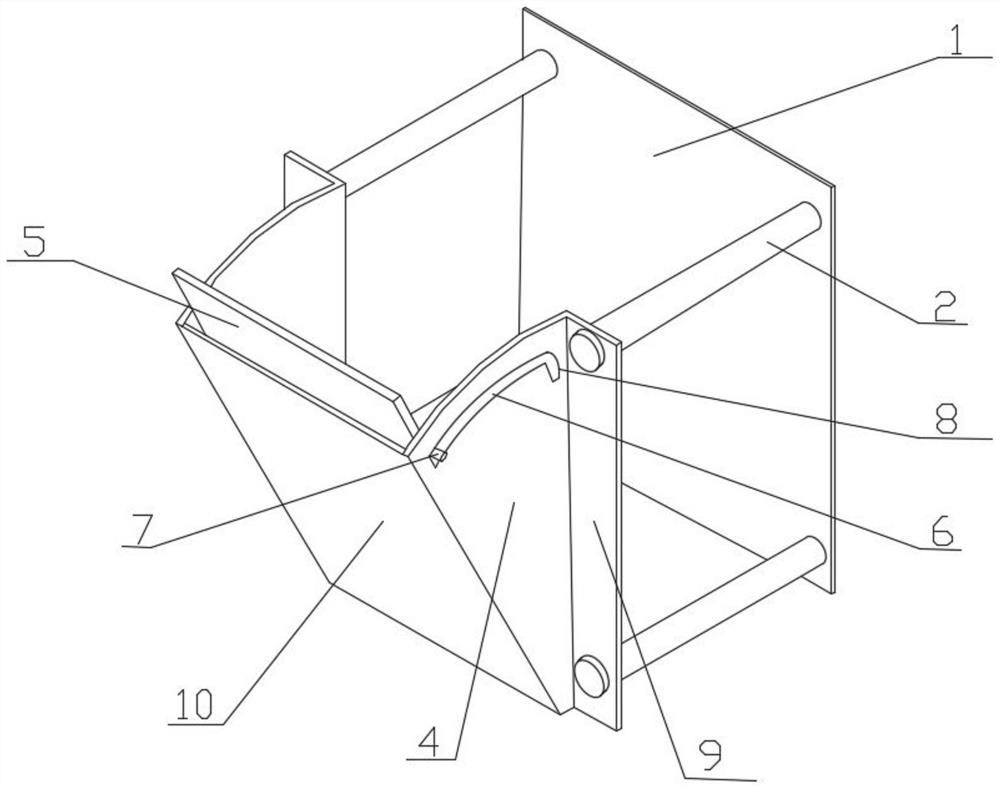

[0043] Such as Figure 1 to Figure 5 As shown, it is an embodiment of the present invention, a construction column free cast-in-place device, including a funnel and a back baffle 1, connecting bolts 2 are connected between the funnel and the back baffle 1, and the connecting bolts 2 are respectively It is detachably connected with the funnel and the tailgate 1, and the connecting bolt 2 is suitable for passing through the masonry 3 on both sides;

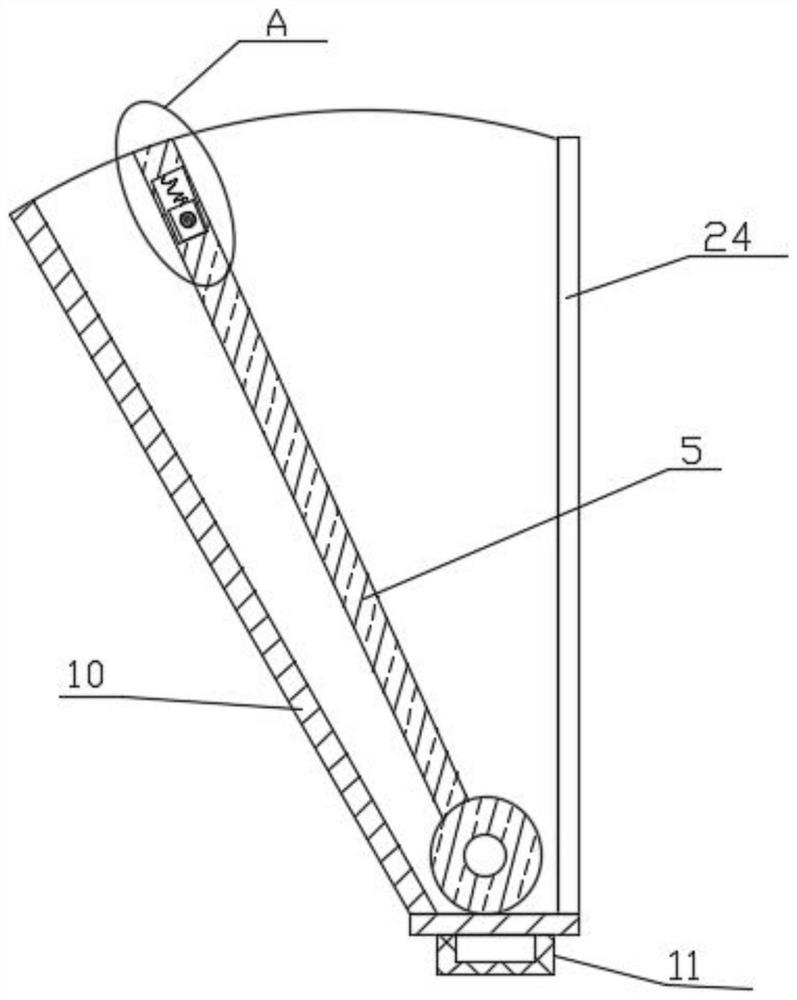

[0044]The funnel part includes connecting side plates 4 and inclined sealing plates 5, the connecting side plates 4 are provided with two groups, the inclined sealing plates 5 are arranged between the two groups of connecting side plates 4, and the inclined sealing plates 5 are rotatably connected with the two groups of connecting side plates 4 , the connecting side plate 4 is provided with an arc-shaped groove 6, the two sides of the oblique sealing plate 5 are provided with limit pins 7, the limit pin 7 is adapted to the arc-shape...

Embodiment 2

[0051] Such as Figure 6 to Figure 11 Shown, is another kind of embodiment of the present invention, on the basis of embodiment 1, add:

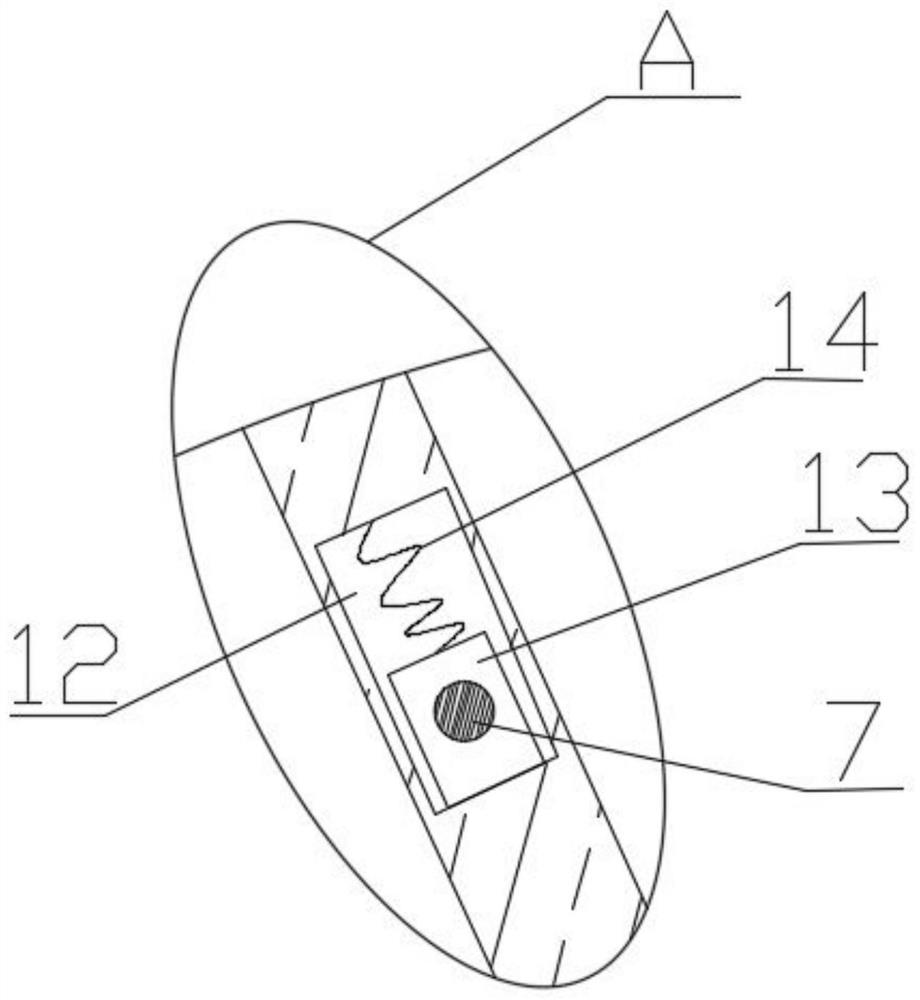

[0052] The upper end of the inclined sealing plate 5 includes a connecting portion 15, which is integrally connected with the inclined sealing plate 5, and the connecting portion 15 is suitable for connecting to the port of the pump tube 16;

[0053] A groove 17 is arranged in the connecting portion 15, and the groove 17 is arc-shaped. A second return spring 18 is installed in the groove 17. A reset plate 19 is installed on the second return spring 18. The reset plate 19 and the second return spring 18 fixed connections;

[0054] A connecting ring 20 is installed on the port of the pump tube 16. The diameter of the connecting ring 20 on one side relative to the rear baffle 1 is smaller than the diameter of the other side. The connecting ring 20 is suitable for clamping on the groove 17. The board 1 is arranged obliquely downward.

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com