Refrigerator defrosting system, refrigerator and refrigerator defrosting method

A refrigerator and branch circuit technology, applied in the field of refrigerator defrosting system, can solve the problems of low defrosting efficiency, high defrosting power consumption, rising temperature of the freezing chamber, etc., and achieve the effect of improving defrosting efficiency and shortening defrosting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

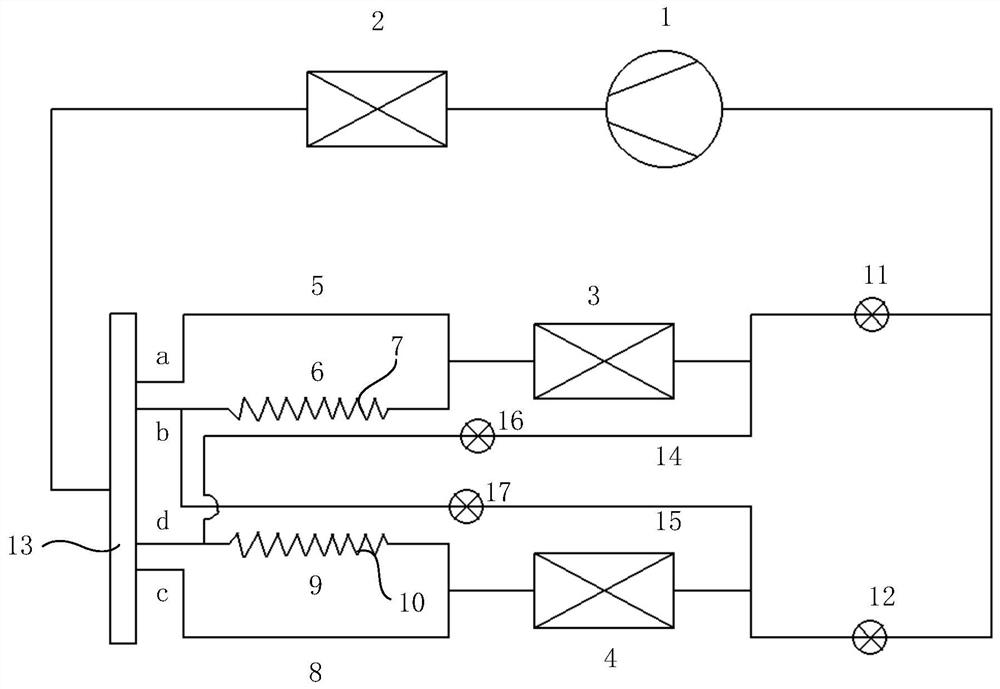

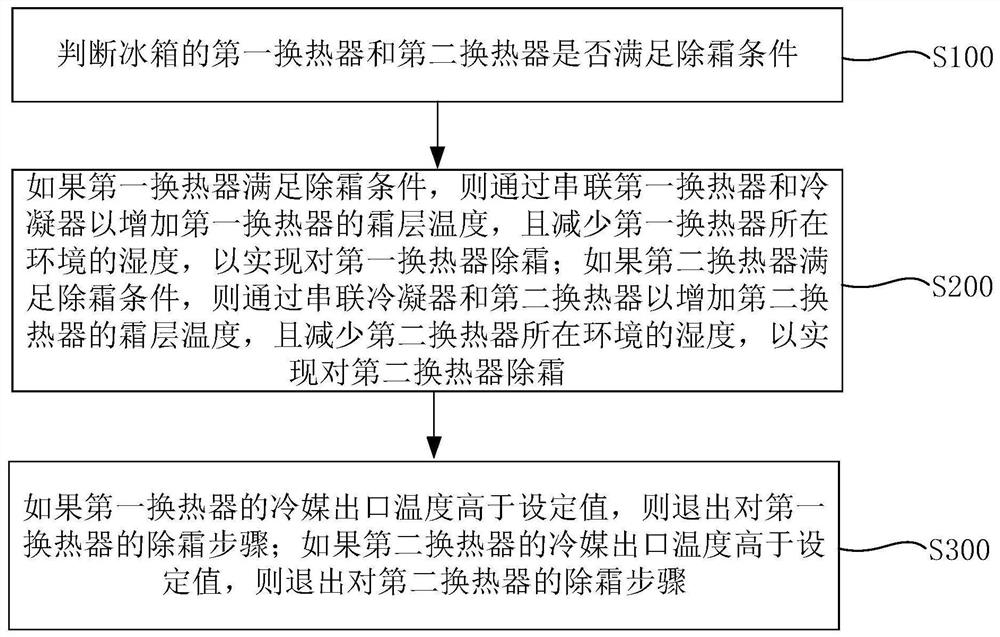

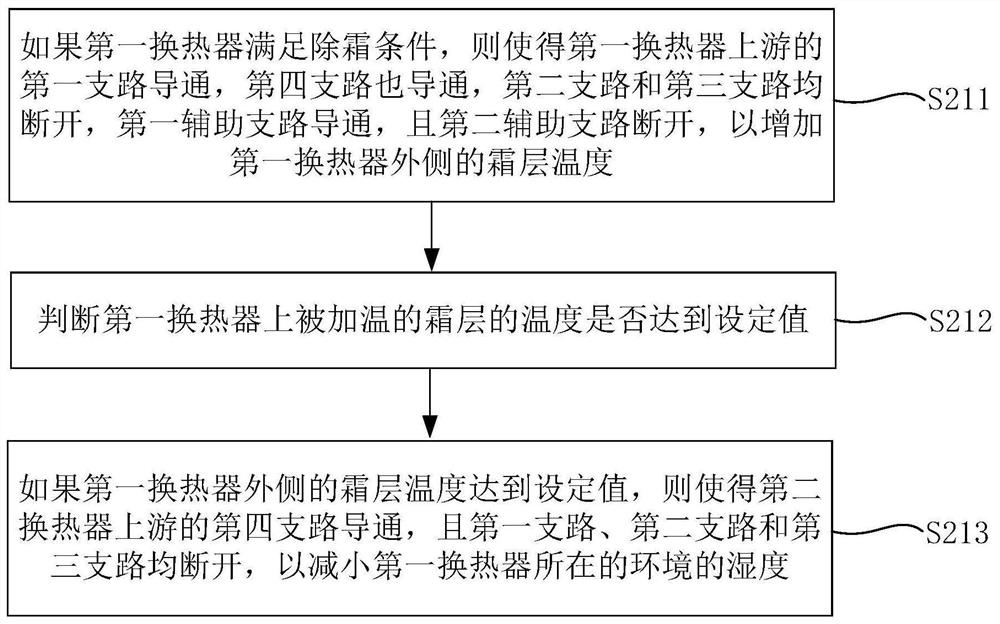

[0047] Combine below Figure 1 ~ Figure 4 The technical solution provided by the present invention is described in more detail.

[0048] see figure 1 An embodiment of the present invention provides a defrosting system for a refrigerator, including a compressor 1 , a condenser 2 , a first heat exchanger 3 , a second heat exchanger 4 , a first auxiliary branch 14 and a second auxiliary branch 15 . The compressor 1 is configured to compress refrigerant. The fluid inlet of the condenser 2 communicates with the fluid outlet of the compressor 1 . A first branch 5 and a second branch 6 are arranged in parallel between the fluid inlet of the first heat exchanger 3 and the fluid outlet of the condenser 2, the first branch 5 is not provided with a throttling element, and the second branch 6 is provided There is a first throttling element 7 ; the fluid outlet of the first heat exchanger 3 communicates with the fluid inlet of the compressor 1 . A third branch 8 and a fourth branch 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com