Self-adjusting road roller capable of preventing local bulge

A self-adjusting, road roller technology, applied in the field of road rollers, can solve problems such as road soil swelling and difficult adjustment, and achieve the effects of convenient expansion and contraction, convenient disassembly and maintenance, and convenient crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

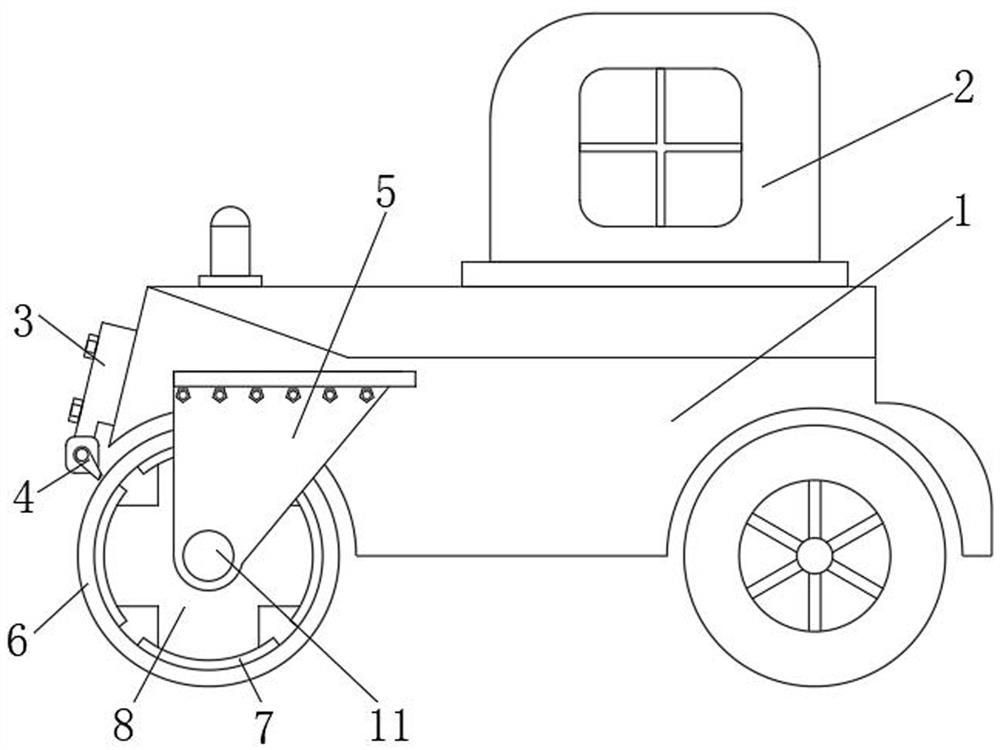

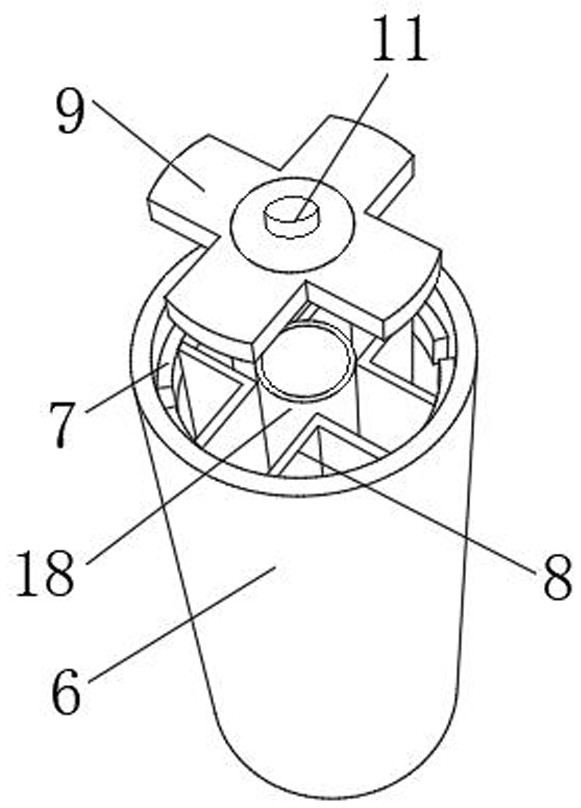

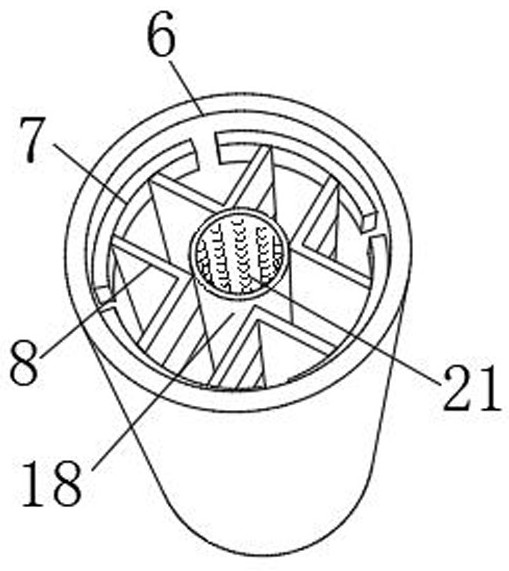

[0041] See Figure 1-7 , A self-adjusting roller of the anti-boreal drum, including the tractor 1, and the upper right upper side of the tractor 1 is fixedly mounted, and the left end of the tractor 1 is fixedly mounted with a baffle mount 3, the baffle mount 3 The lower end is connected to the fender 4, and the front and rear ends of the tractor 1 are fixedly mounted, and the inside of the side shaft mount 5 is connected to the inside of the side shaft mount 5, the inner side wall of the compacted roller 6. The fixed axis 7 is fixedly mounted, and the inner end of the paste shaft 7 is fixedly mounted and mounted, the front end of the mounting rail 8 is fixedly connected to the sealing end cover 9, and the inside peripheral periphery of the sealing end cover 9 is fixedly connected to the flange 10 The inner portion of the sealing end cover 9 is fixedly mounted, and the inside of the mounting rail 8 is fixedly mounted, the gravity touch sensor 12 is attached, the outer surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com