Anti-scratch energy-saving wall module

An anti-scratch and anti-scratch film technology, applied in building components, thermal insulation, covering/lining, etc., can solve the problems of poor waterproof effect on inner walls, no anti-scratch mechanism on inner walls, wall damage, etc. To achieve the effect of improving the waterproof sealing effect, improving the effect of connecting and assembling, and improving the firmness of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

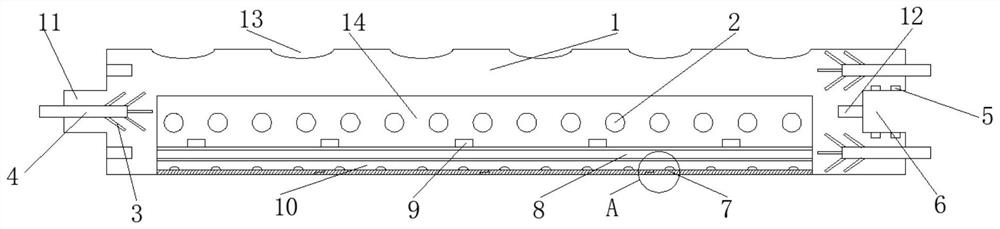

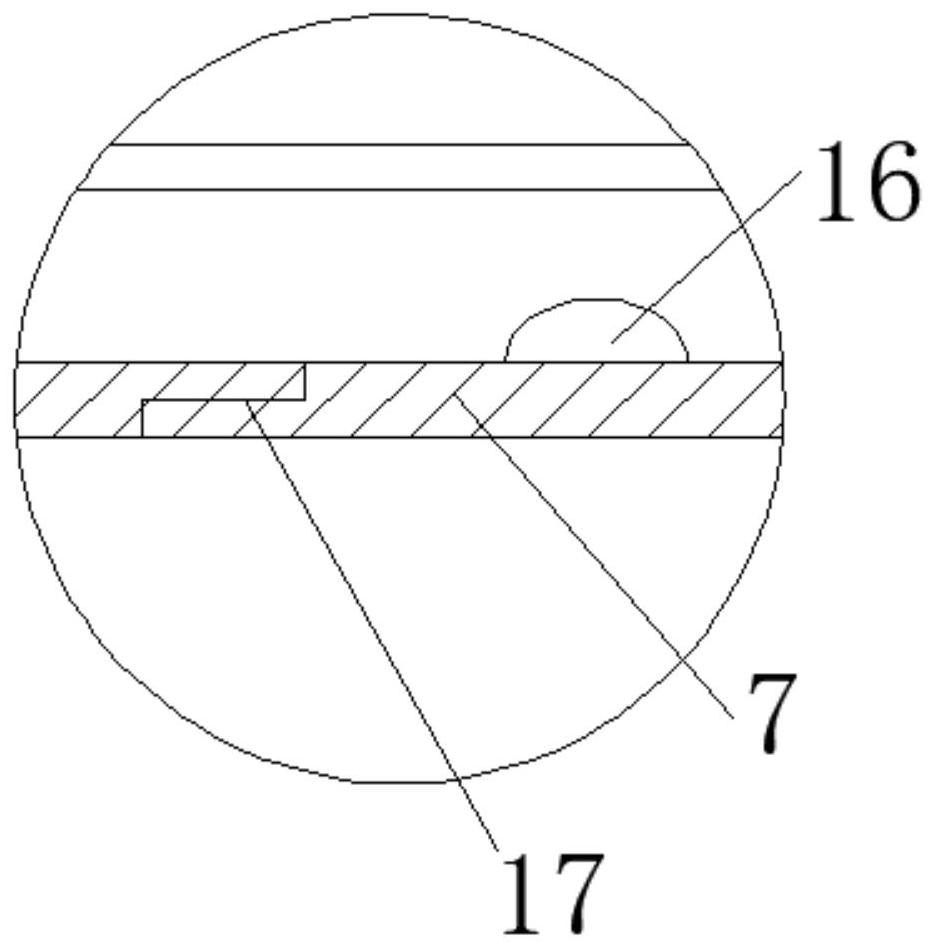

[0021] see figure 1 with image 3 , the present invention provides a technical solution: an anti-scratch energy-saving wall module, including a base wall 1, a connector 11 is fixed at one end of the base wall 1, and a strengthening mechanism is arranged on the inner side of the connector 11, and the base wall 1 The other end is provided with a first connection groove 6, which is convenient for connecting and fixing two base walls 1. The lower surface of the base wall 1 is provided with an expanded polystyrene board 14, which is convenient for heat preservation. The lower surface of the expanded polystyrene board 14 is passed through the anti-cracking glue A galvanized steel mesh 8 is fixed, and a waterproof putty layer 10 is arranged on the lower surface of the galvanized steel mesh 8 to facilitate a better waterproof effect. The lower surface of the waterproof putty layer 10 is fixed with an OPP anti-scratch film 7, which is convenient to improve the inner surface of the base...

Embodiment 2

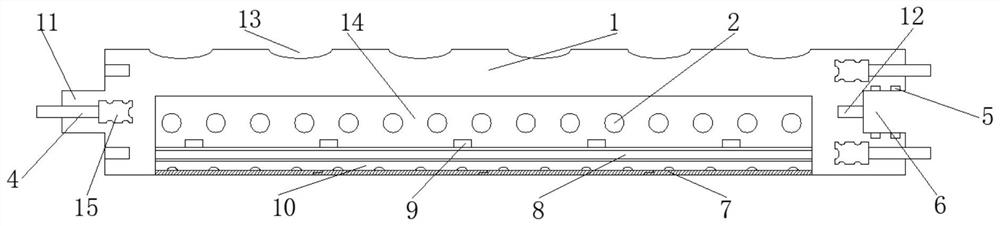

[0029] see figure 1 , figure 2 with image 3 , the present invention provides a technical solution: an anti-scratch energy-saving wall module, including a base wall 1, a connector 11 is fixed at one end of the base wall 1, and a strengthening mechanism is arranged on the inner side of the connector 11, and the base wall 1 The other end is provided with a first connection groove 6, which is convenient for connecting and fixing two base walls 1. The lower surface of the base wall 1 is provided with an expanded polystyrene board 14, which is convenient for heat preservation. The lower surface of the expanded polystyrene board 14 is passed through the anti-cracking glue A galvanized steel mesh 8 is fixed, and a waterproof putty layer 10 is arranged on the lower surface of the galvanized steel mesh 8 to facilitate a better waterproof effect. The lower surface of the waterproof putty layer 10 is fixed with an OPP anti-scratch film 7, which is convenient to improve the inner surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com