Integrated brake caliper assembly

A brake caliper, integrated technology, applied in the direction of brake parts, brake types, brake components, etc., can solve the problem that the elastic potential energy is not fully utilized, the brake caliper assembly has a small contribution to reducing drag, and the friction block cannot be used. Moving and other problems, to achieve the effect of improving the competitiveness of market products, overcoming vibration, and returning to a thorough and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

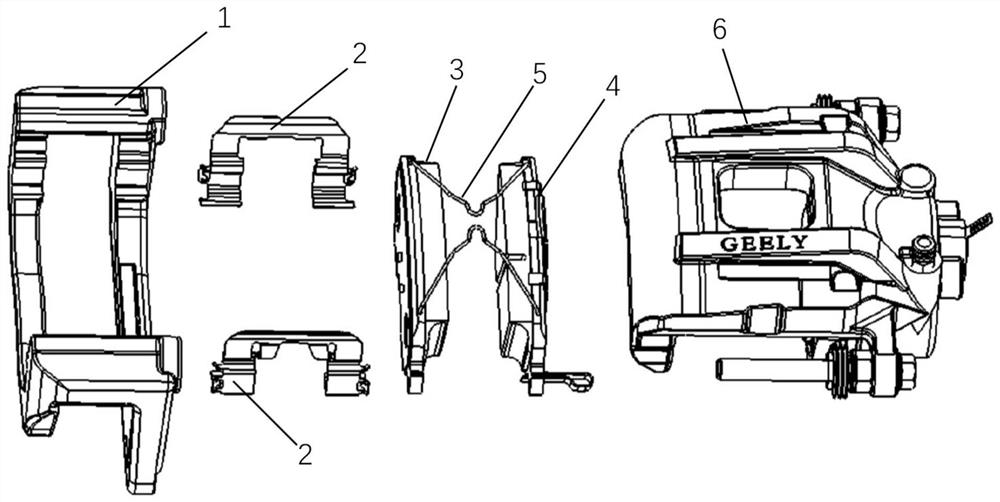

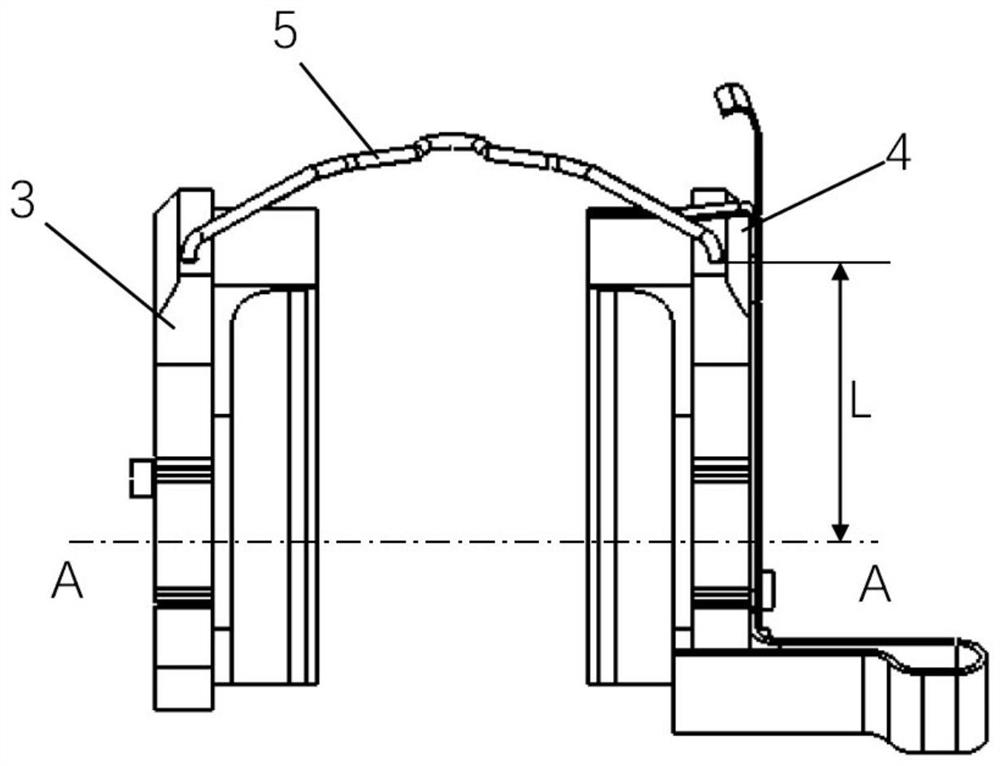

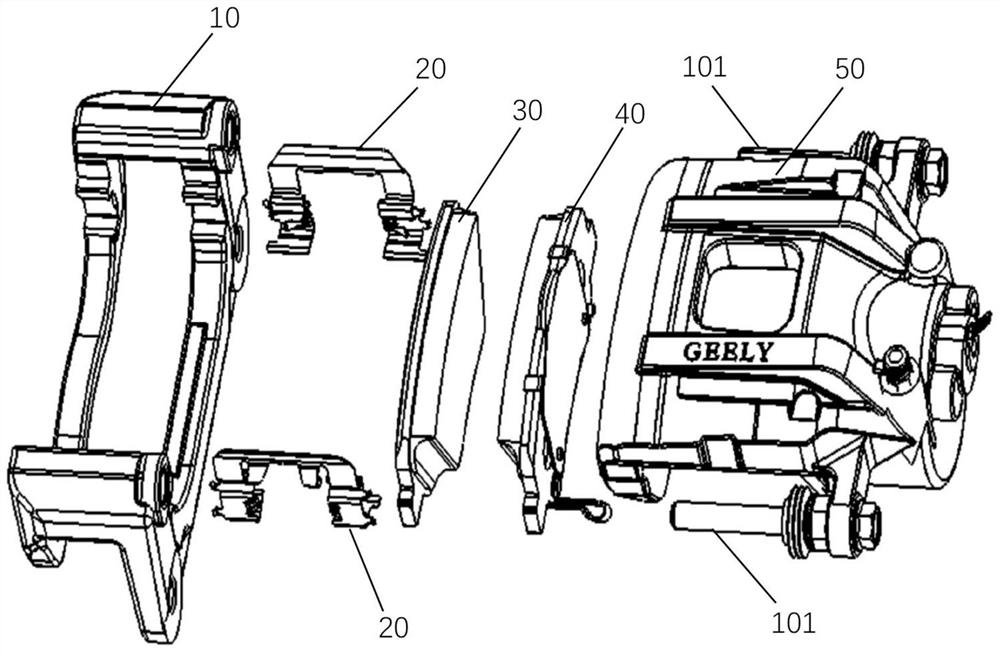

[0038] image 3 It is an exploded schematic diagram of an integrated brake caliper assembly according to an embodiment of the present invention. Figure 4 It is an assembly schematic diagram of a group of integrated return spring pieces 20 , outer friction blocks 30 and inner friction blocks 40 of the integrated brake caliper assembly according to an embodiment of the present invention. like image 3 As shown, in one embodiment, the integrated brake caliper assembly includes a caliper body bracket 10 , two integrated return spring pieces 20 , two outer friction blocks 30 and two inner friction blocks 40 . The two integrated return spring sheets 20 are respectively fixed on the two sides of the caliper bracket 10 along the radial direction of the wheel (see Figure 4 ), each integrated return spring sheet 20 is clamped with the outer friction block 30 and the inner friction block 40 at preset positions on both sides along the wheel axis, respectively. like Figure 4 As sho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap