Steel structure gravity center detection and correction method and system

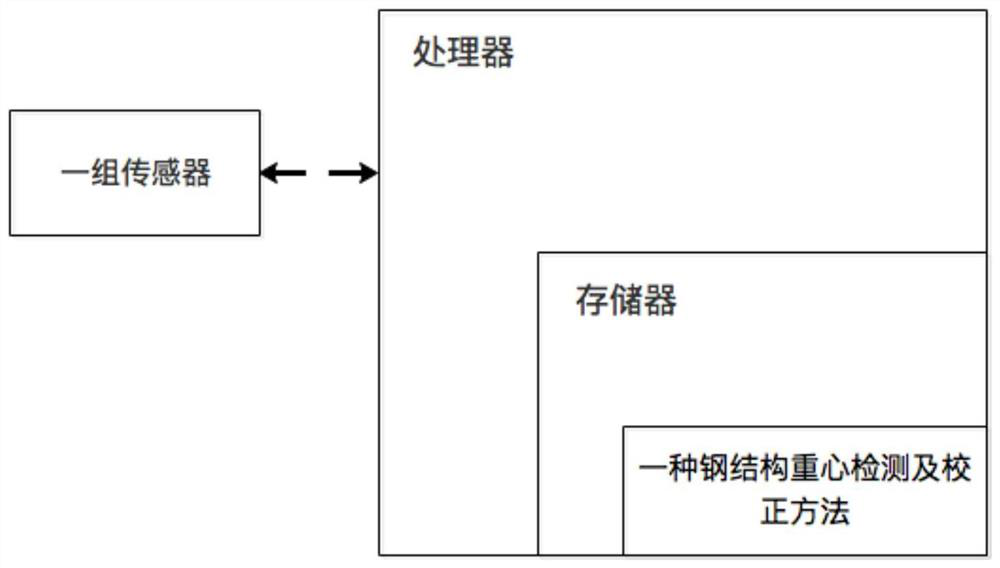

A correction method and steel structure technology, applied in the testing of machines/structural components, measuring devices, static/dynamic balance testing, etc., can solve problems such as inability to effectively detect the influence of the center of gravity, no detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The preferred embodiment of the present invention will be described in detail below.

[0051] The steel structure of the present invention can be applied to different application scenarios, such as assembled building construction, industrial building construction, traditional construction, repair bridge repair path, etc., for different application scenarios, access within the construction area Steel structural installation information and center of gravity are different.

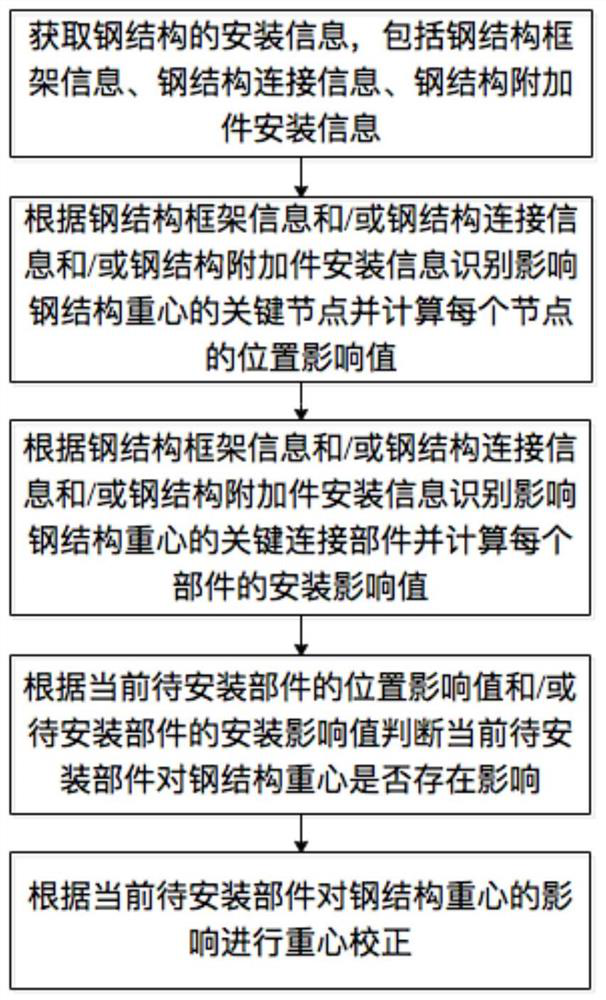

[0052] The stencil structure of the steel structure of the present invention and an embodiment of the correction method are characterized in that:

[0053] Get installation information of the steel structure, including steel structure frame information, steel structure connection information, steel structure attachment installation information;

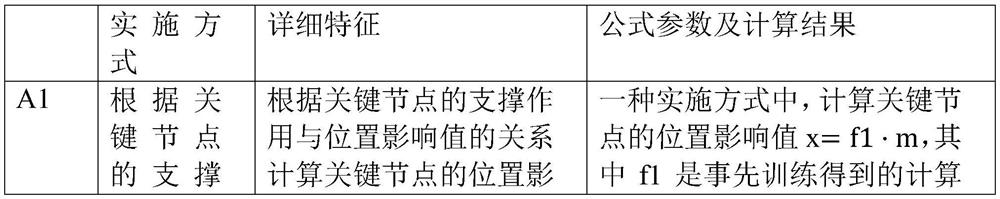

[0054] According to the steel structure frame information and / or steel structure connection information and / or steel structural attachment installation infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com