Wire arranging device for winding of transformer iron core

A technology of transformer iron core and wire management device, which is applied in inductance/transformer/magnet manufacturing, coil manufacturing, electrical components, etc., can solve the problems of transformer coils that are not wound neatly, copper wires cannot be arranged, and transformer quality is not up to standard, etc. To achieve the effect of avoiding reverse buckle and avoiding loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

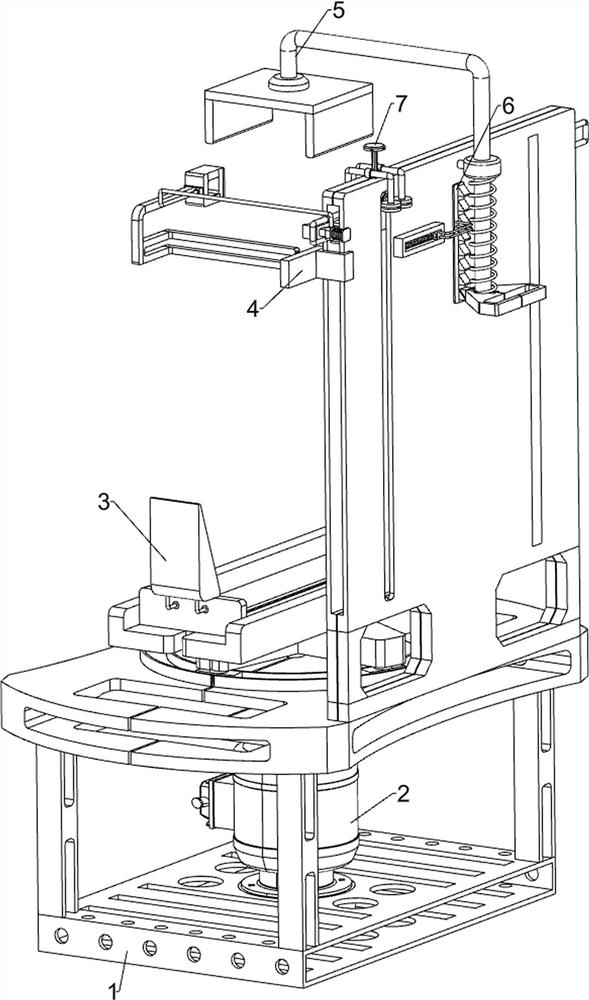

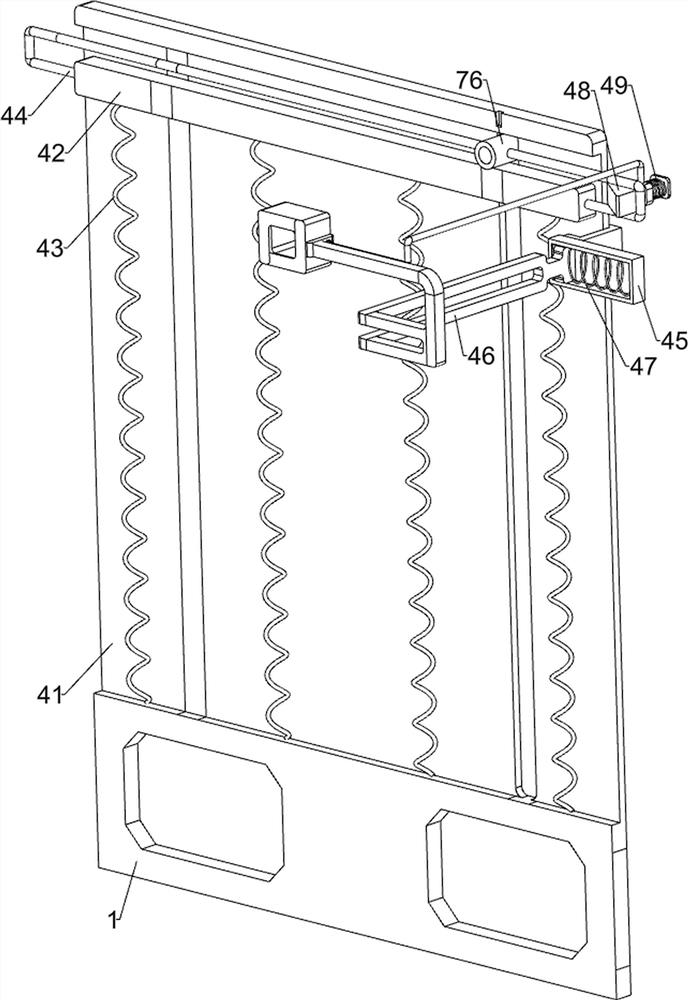

[0022] A wire management device for transformer core winding, such as Figure 1-5 As shown, it includes a base 1, a rotating assembly 2, a clamping assembly 3 and a cable management assembly 4. The base 1 is provided with a rotating assembly 2 that rotates by rotating, and the rotating assembly 2 is provided with a clamping assembly that slides. The clamping assembly 3 is tight, and the base 1 is provided with a wire management assembly 4 for wire management by sliding.

[0023] When using this device, the staff first puts the transformer body on the clamping assembly 3 and fixes it. After putting it in place, the staff starts the rotating assembly 2, and the rotating assembly 2 drives the clamping assembly 3 to rotate for winding. At the same time, the copper wires can be sorted through the wire management assembly 4 .

[0024] Such as figure 1 and figure 2 As shown, the rotating assembly 2 includes a geared motor 21, a rotating rod 22, a circular guide rail 23, an arc-sh...

Embodiment 2

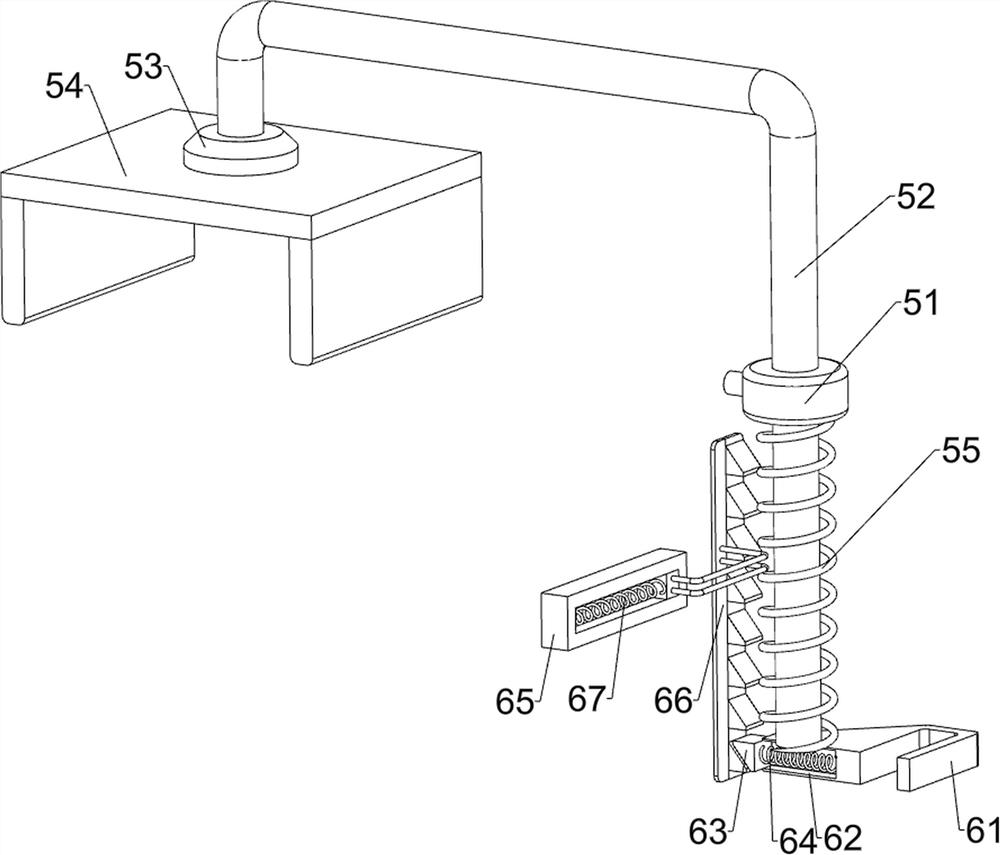

[0031] On the basis of Example 1, such as figure 1 and Figure 4 As shown, a fixed assembly 5 is also included, and the fixed assembly 5 includes a sliding sleeve 51, a sliding rod 52, a circular block 53, a U-shaped plate 54 and a fifth spring 55, and the upper right side of the base 1 is provided with a sliding sleeve 51. Sliding type is provided with slide bar 52 in cover 51, and the rotary type on slide bar 52 is provided with circular block 53, and circular block 53 is provided with U-shaped plate 54, and is wound around between slide bar 52 and sliding sleeve 51 and is connected with the fifth. Spring 55.

[0032] When using this device, before placing the transformer, the staff first pushes the sliding rod 52 to slide upward in the sliding sleeve 51, the fifth spring 55 is compressed, and the sliding rod 52 moves upward through the circular block 53 to drive the U-shaped plate 54 to move upward After the transformer is put away, the staff releases the sliding rod 52, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com