Packaging structure for light emitting diode light source

A technology of light-emitting diodes and packaging structures, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of low voltage efficiency and current fluctuations, achieve short circuit connections, increase life, and save coating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

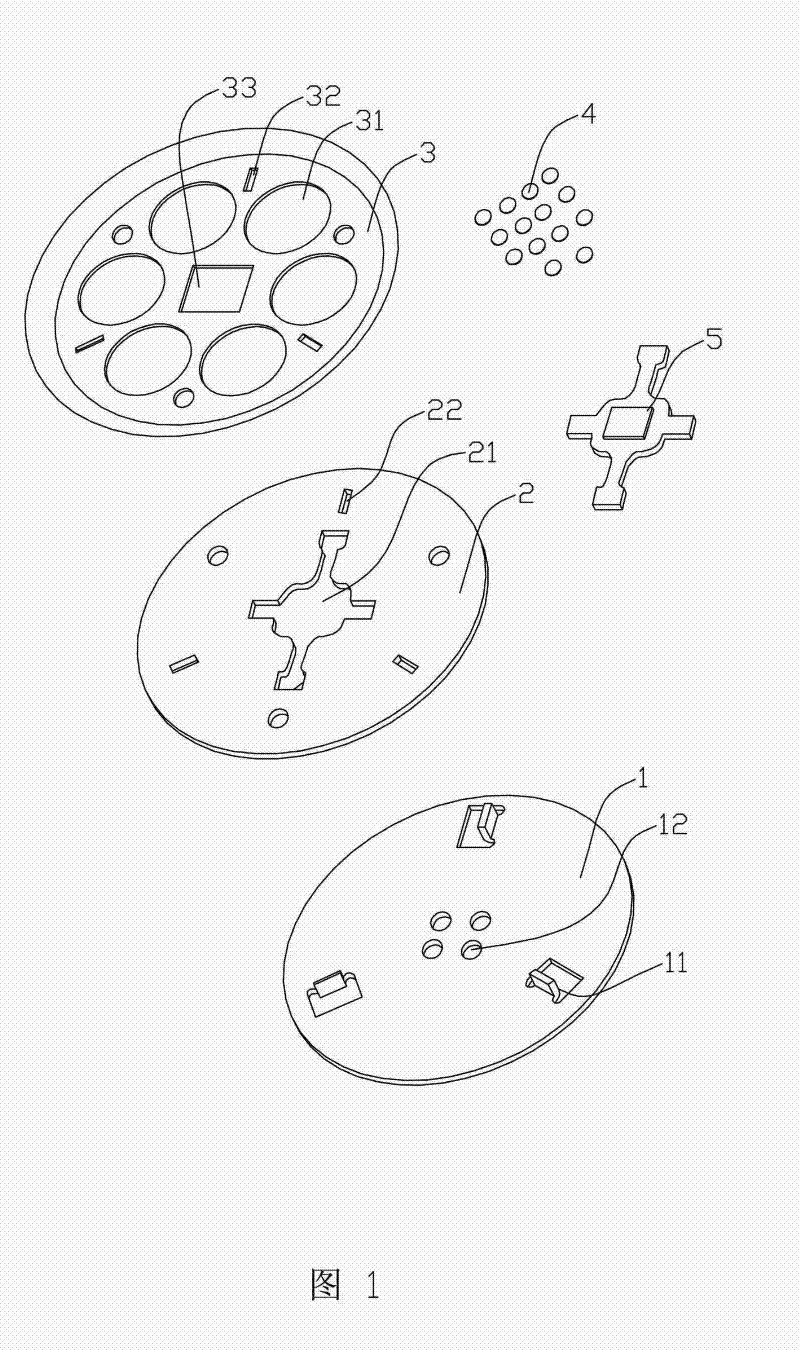

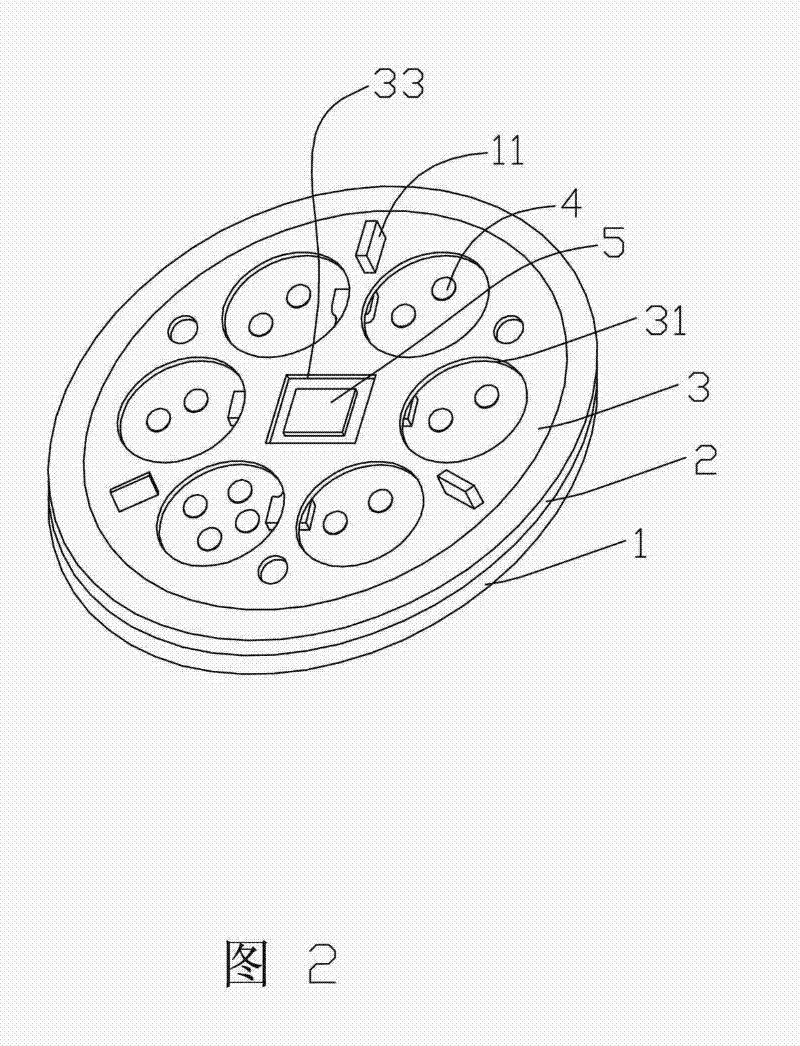

[0026] Such as figure 1 , figure 2 As shown, a package structure of a light-emitting diode light source includes a first stamped metal sheet 1, a second stamped metal sheet 2, and a third stamped metal sheet 3 in a circular structure, which are attached to the second stamped metal sheet 2. The light-emitting diode chip 4, the PCB circuit board 5 connected with the light-emitting diode chip 4, the second stamping metal sheet 2 is provided with the installation port 21 that can fix the PCB circuit board 5, and the third stamping metal sheet 3 is provided with There are six openings 31 that limit the areas of fluorescent powder glue, and the above-mentioned light-emitting diode chips 4 are attached to the six areas of the second punched metal sheet 2 corresponding to the through holes 31; the second punched metal sheet 2 is along the The second stamped metal sheet 2 is evenly arranged with three bayonet sockets 22 on the circumference, and the third stamped metal sheet 3 is eve...

Embodiment 2

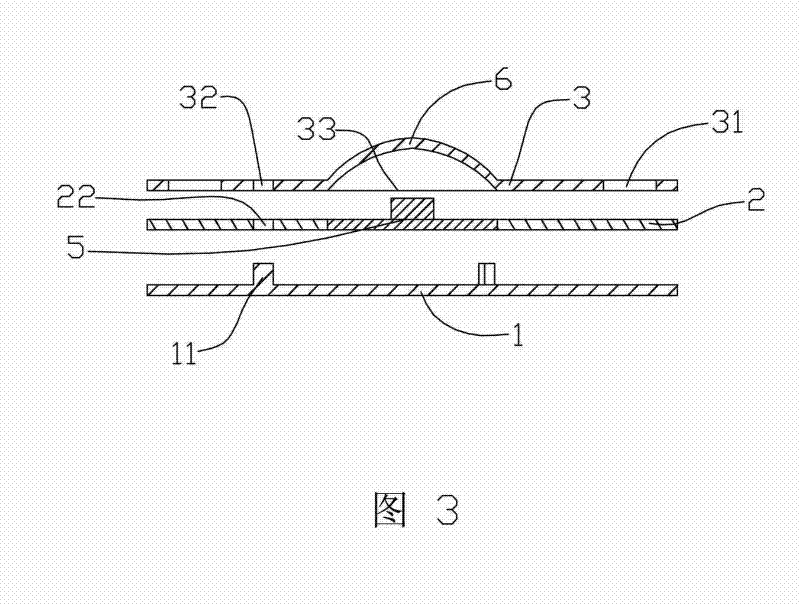

[0032] This embodiment is roughly the same as Embodiment 1, as image 3 , Figure 4 As shown, only a convex portion 6 is provided at the position of the limit opening 33 of the third punched metal sheet 3, the convex portion 6 is conical or arc-shaped, and the convex portion 6 can cover the PCB circuit board 5 to avoid The light is absorbed by the PCB circuit board 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com