Motor, motor control method, vehicle and medium

A technology of axis direction and components, applied in the direction of motor control, control system, control of mechanical energy, etc., can solve problems such as efficiency reduction, and achieve the effect of changing working characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

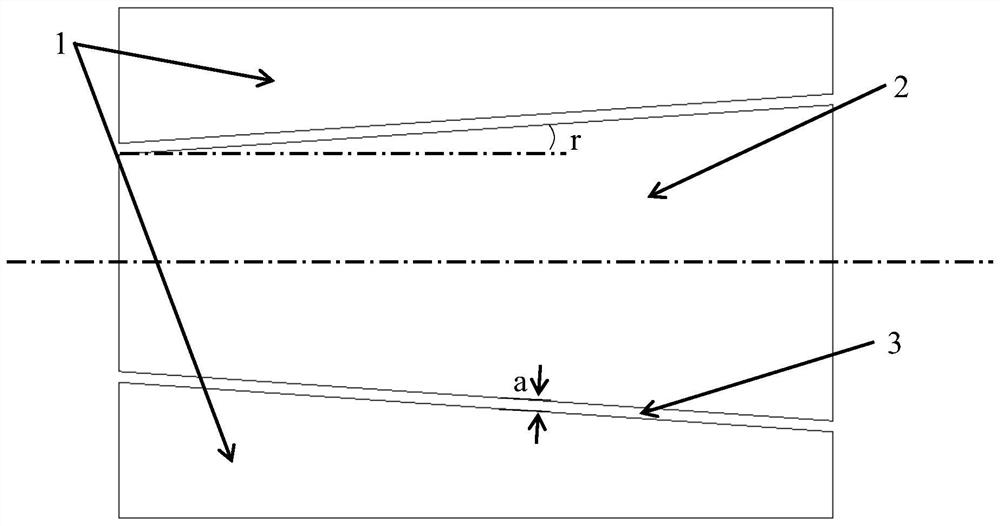

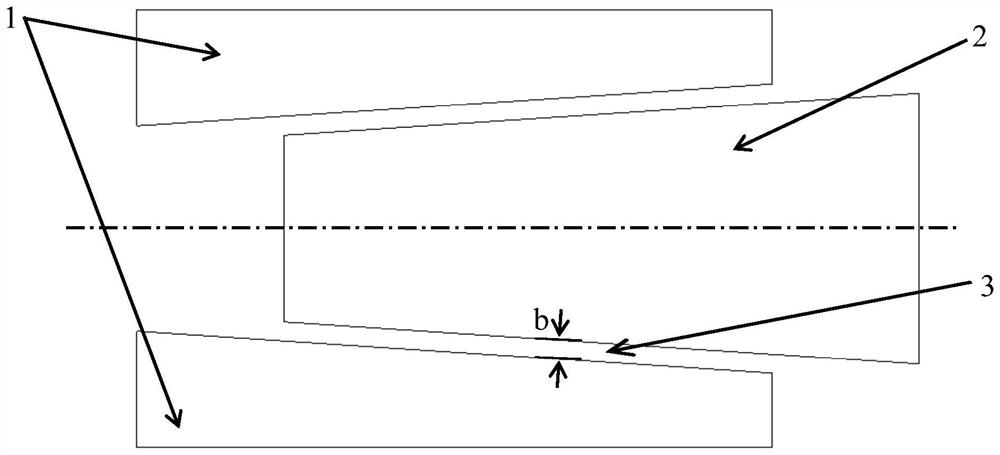

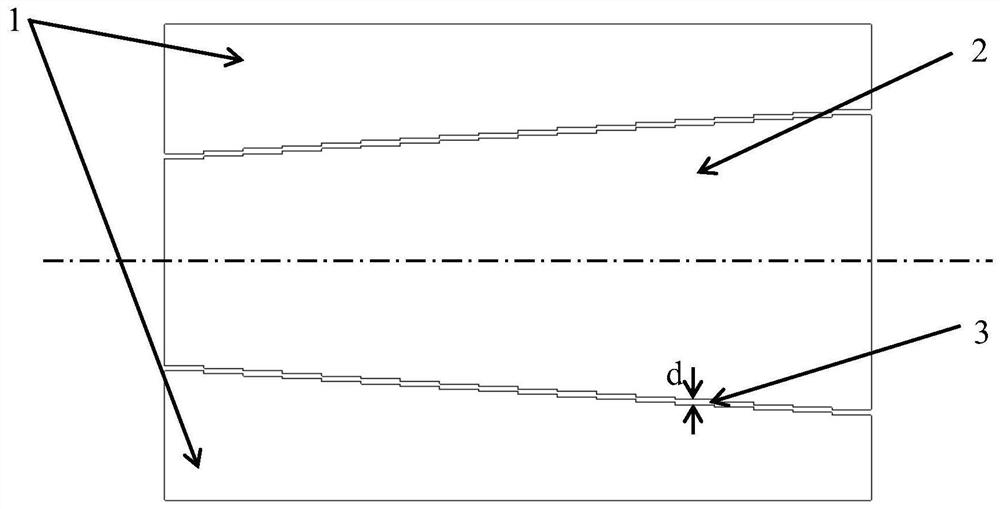

[0034] One of the core concepts of the embodiments of the present invention is that there is an air gap between the first component and the second component, and the plane where the contour of the outer surface of the second component is located intersects the axis of the second component, so that when the first When the component and the second component move relative to each other in the direction of the axis, the length of the air gap changes immediately, thereby providing a motor with adjustable air gap. By adjusting the length of the air gap of the motor, the working characteristics of the motor are changed, so that It is more suitable for the needs of the current working conditions.

[0035] refer to figure 1 , shows a topo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com