Electronic parts

A technology of electronic components and internal components, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as wiring disconnection, low productivity, and large processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0180] On the upper surface of a sheet-like substrate with a thickness of 20 μm composed of a silicon wafer constituting the movable piece, an oxide film with a thickness of 1.4 μm, a bottom electrode with a thickness of 0.3 μm, a piezoelectric element with a thickness of 2 μm, and an upper electrode with a thickness of 0.3 μm are stacked sequentially. The electrode is a micro relay composed of a movable piece, the overall thickness is 24μm, the span is 4mm, and the width is 0.8mm, and the contact load and the deformation relative to the applied voltage are calculated. The calculation results are shown in Figs. 37A and 37B.

[0181] According to FIG. 37A and FIG. 37B, it can be seen that a specific contact pressure and displacement can be obtained only by controlling the voltage applied to the piezoelectric element.

no. 2 example

[0183] A heating layer with a depth of 3 μm is formed in the surface layer of a thin sheet-shaped substrate composed of a silicon wafer constituting a movable piece with a thickness of 20 μm, and an insulating oxide film with a thickness of 1.1 μm is formed on the upper surface of the heating layer. The micro relay composed of moving pieces has an overall thickness of 21.1μm, a span of 4mm, and a width of 0.8mm. Calculate the contact load and the deformation relative to the applied voltage. The calculation results are shown in Figs. 38A and 38B.

[0184] According to FIGS. 38A and 38B, it can be seen that only by controlling the applied voltage to adjust the heating value of the heating layer, a specific displacement and contact pressure can be obtained.

[0185] Matrix relays of fourteenth to seventeenth embodiments for achieving the second object will be described below with reference to FIGS. 39A to 45 .

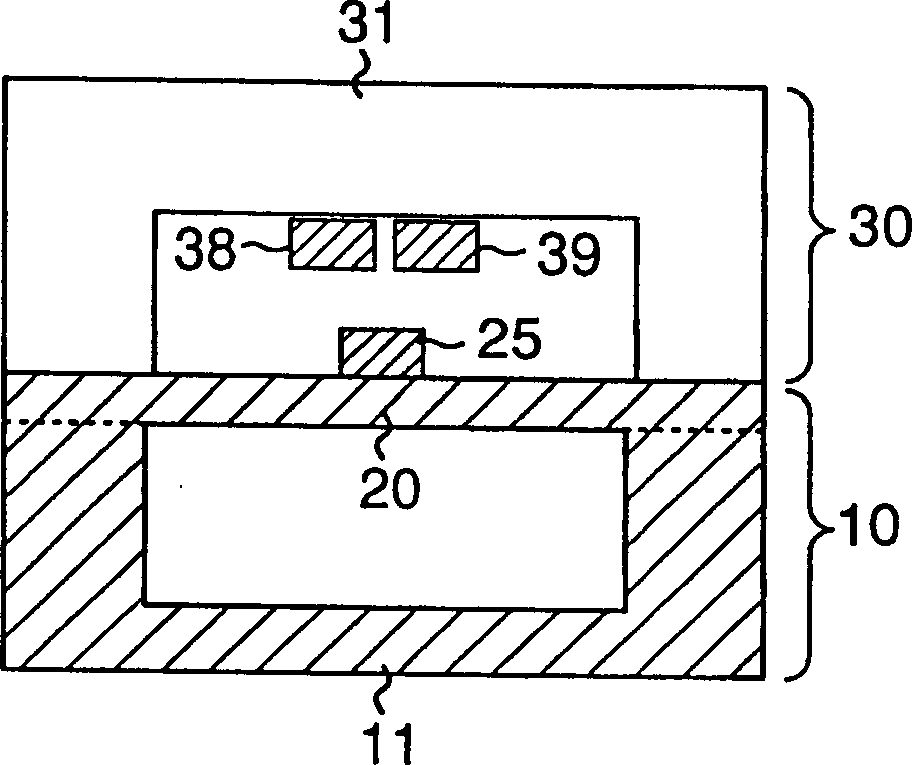

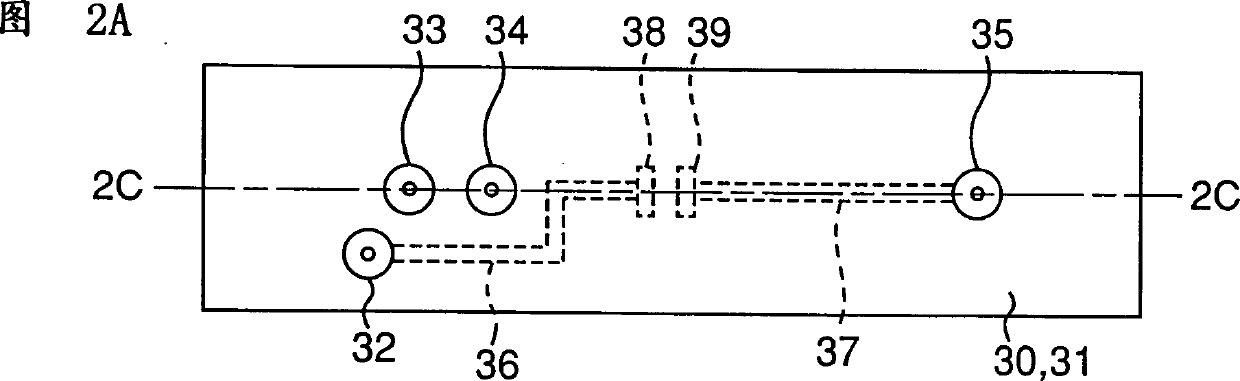

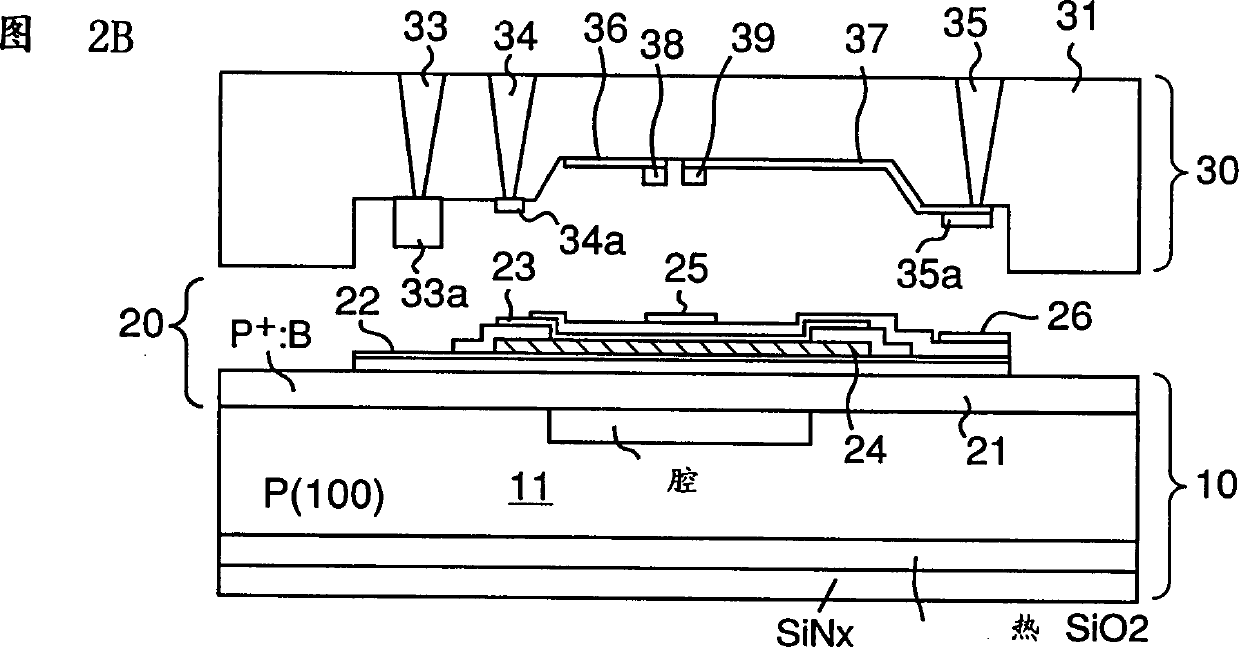

[0186] As shown in FIGS. 39A and 41B , the fourteenth embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com