Warp knitting machine

A technology of warp knitting machine and transmission mechanism, applied in the field of warp knitting machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

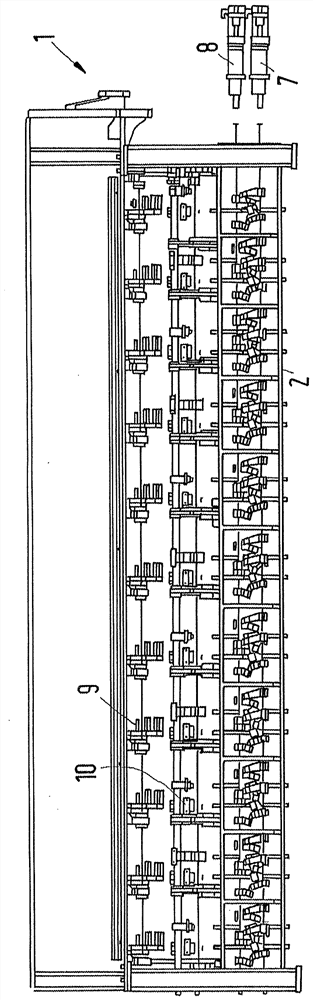

[0027] figure 1 A warp knitting machine 1 with a needle bed 2 is shown in very schematic form. The warp knitting machine 1 has a plurality of bars, not further shown, each of which carries a knitting tool. The bars are suspended from levers 9 , 10 which are driven by drives arranged in the needle bed 2 .

[0028] The combs have a longitudinal orientation. The longitudinal direction corresponds to the figure 1 The width direction of the warp knitting machine 1 shown in, that is, refer to figure 1 The diagram extends from left to right.

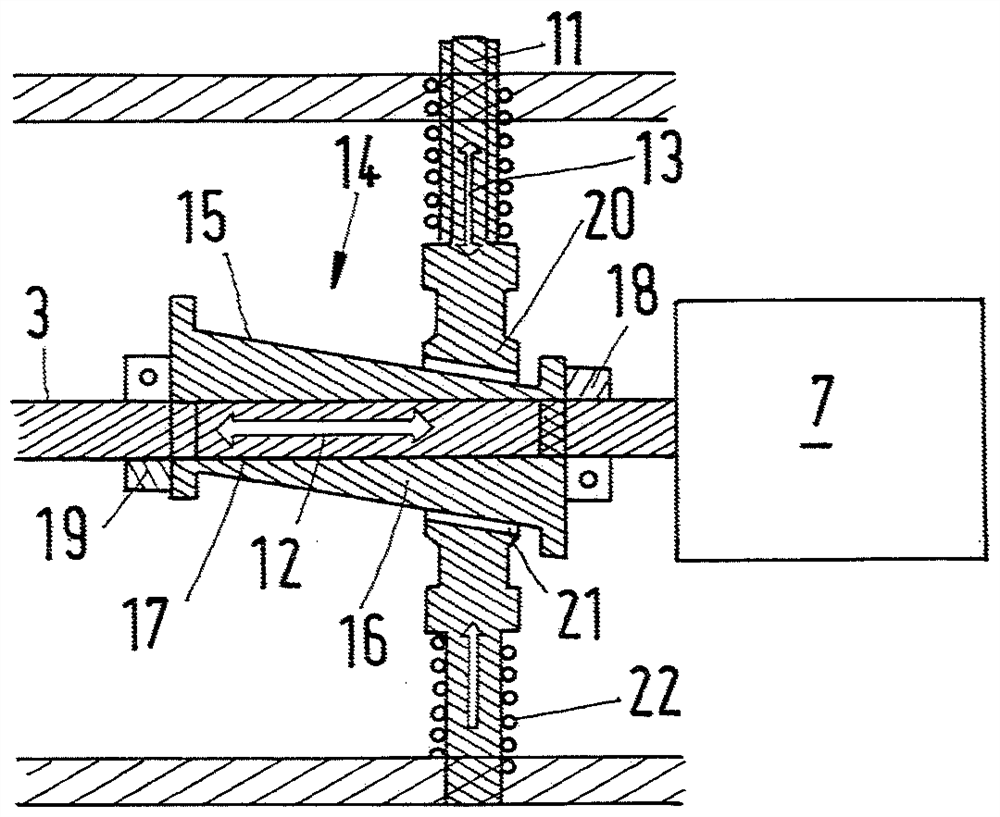

[0029] figure 2 The needle bed 2 with a plurality of drive plungers 3-6 is shown in a somewhat enlarged view. Each drive push rod 3-6 is in connection with a drive motor 7,8. exist figure 1 In the illustration of , the drive motors 7 , 8 are arranged at one end of the warp knitting machine 1 . However, the drive motors 7 , 8 can also be arranged at both ends of the warp knitting machine 1 .

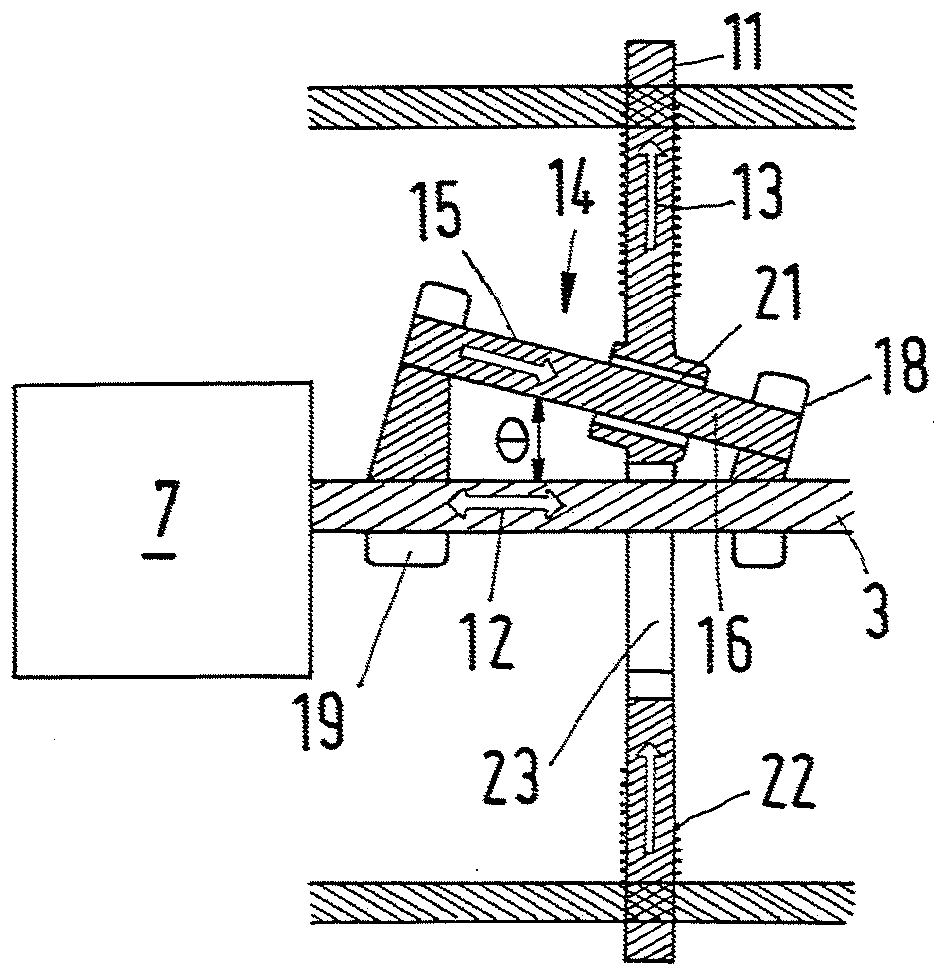

[0030] The drive motors 7, 8 drive the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com