Coating tool and coating method

A tool and coating technology, applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of difficult installation, large installation space, difficult to operate advance and retreat regulators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach >

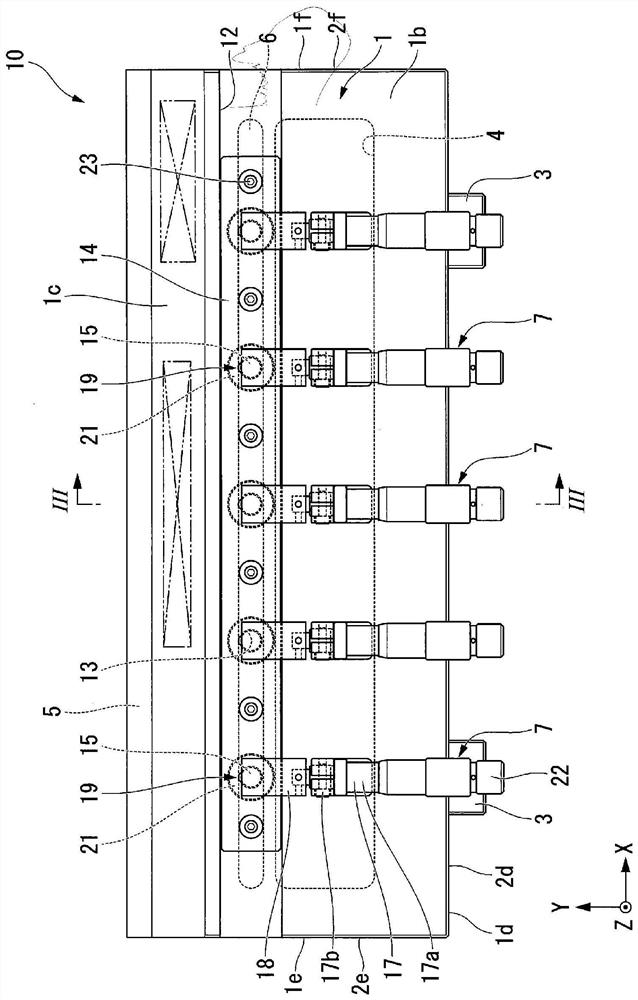

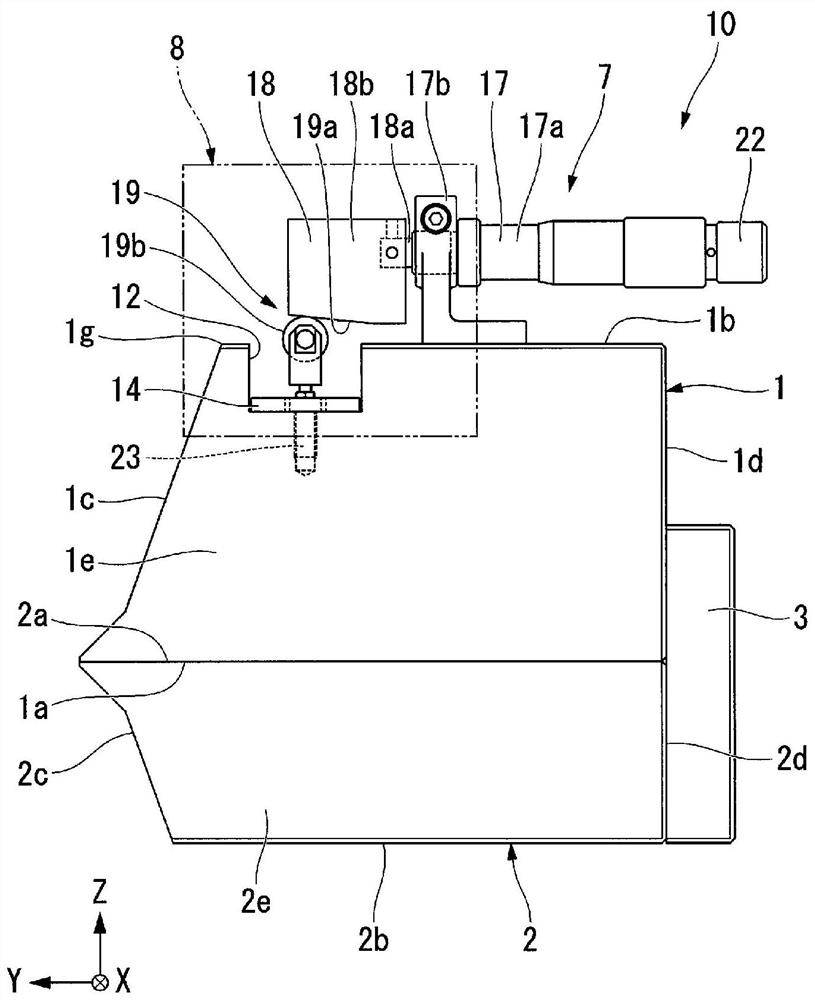

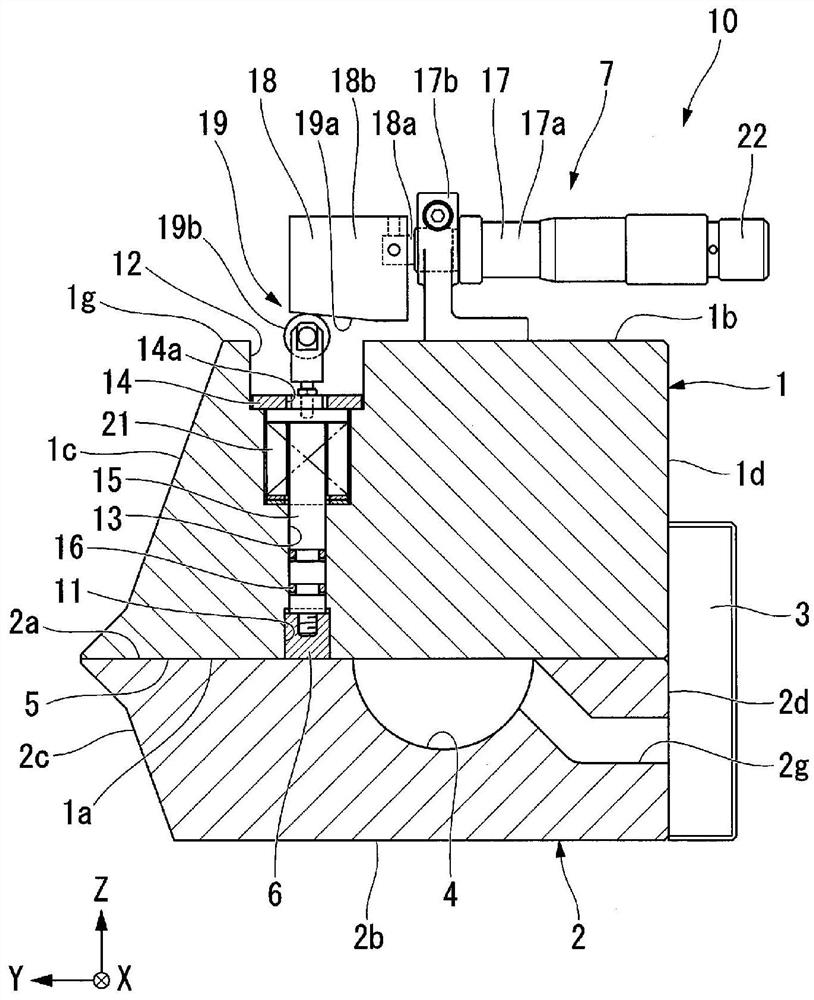

[0065] Below, refer to Figure 1 to Figure 5 , the coating tool 10 according to the first embodiment of the present invention will be described.

[0066] The coating tool 10 of the present embodiment is, for example, a so-called roll-to-roll (ROLL TO ROLL) slot die for coating a coating liquid on the surface of a film, metal foil, or other object to be coated.

[0067] Such as Figure 1 to Figure 5 As shown, the coating tool 10 of this embodiment includes a first head member 1, a second head member 2, a spacer member (not shown), a positioning block 3, a manifold 4, a slot 5, and a throttle rod. 6. The adjustment mechanism 7 and the cover body 8 .

[0068] The first head member 1 and the second head member 2 each have a substantially rectangular plate shape or a substantially cuboid shape. The first head member 1 and the second head member 2 are arranged adjacent to each other with their inner surfaces facing each other.

[0069] [Definition of directions used in this embo...

no. 2 Embodiment approach >

[0169] Next, refer to Figure 6 ~ Figure 8 Next, the coating tool 20 according to the second embodiment of the present invention and a coating method for coating a coating liquid on an object to be coated using the coating tool 20 will be described. In addition, in the second embodiment, the same reference numerals are assigned to the same constituent elements as those in the first embodiment, and description thereof will be omitted.

[0170] In addition to the first head member 1, second head member 2, spacer member (not shown), positioning block 3, manifold 4, slot 5. In addition to the throttle rod 6, the adjustment mechanism 7 and the cover body 8, a coating film thickness detection mechanism (not shown) and a control unit (not shown) are also provided.

[0171] Furthermore, the configuration of the adjustment mechanism 7 of the applicator 20 is different from the configuration of the adjustment mechanism 7 of the applicator 10 described in the above embodiment.

[0172]...

no. 3 Embodiment approach >

[0197] Next, refer to Figure 9 ~ Figure 11 , the coating tool 30 according to the third embodiment of the present invention will be described. The structure of the applicator 30 of the third embodiment is partially different from the structure of the applicator 10 described in the first embodiment. In addition, in this embodiment, the same code|symbol is attached|subjected to the same component as the above-mentioned embodiment, and the description is abbreviate|omitted.

[0198] Such as Figure 9 ~ Figure 11 As shown, the applicator 30 of the present embodiment includes the first head member 1, the second head member 2, the spacer member (not shown), and the positioning block 3 included in the applicator 10 of the first embodiment. , the manifold 4, the slot 5, the throttle rod 6, the adjustment mechanism 7, and the cover 8 (not shown), a fixing portion 25 is also provided.

[0199] In addition, the configuration of the adjustment mechanism 7 of the applicator 30 is parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com