Method for calibrating adjustment means for adjusting a die gap of an outlet die for a film web on a flat film machine

A technology for adjusting mechanisms, outlet nozzles, applied in applications, flat products, household appliances, etc., which can solve the problems of high time, high time expenditure and production loss, lack of repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

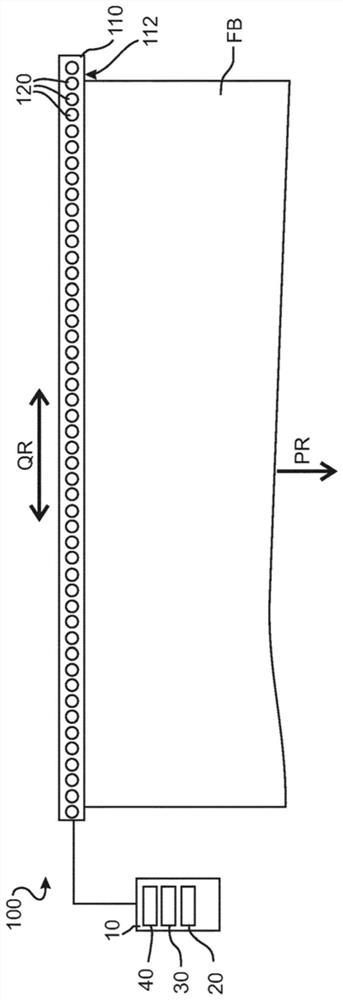

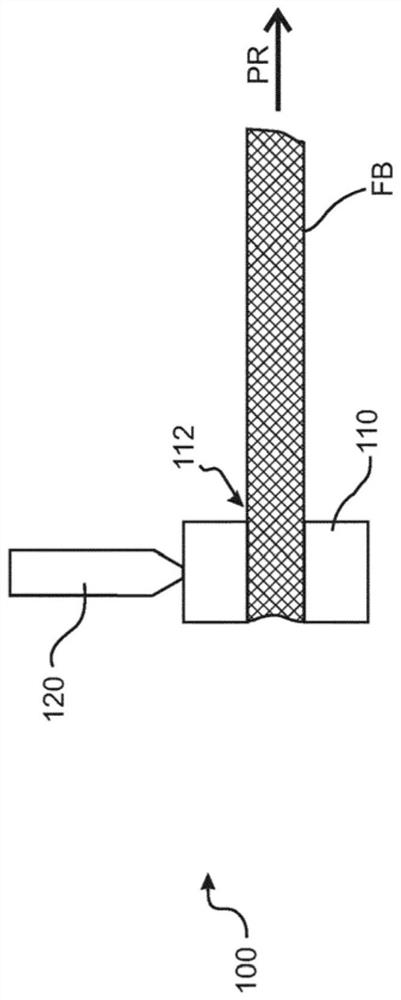

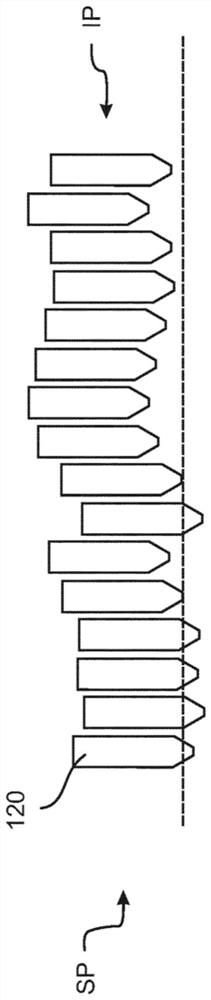

[0032] figure 1 and figure 2 Shown is a film flattener 100 in which a nozzle slot 112 of an outlet nozzle 110 is provided over the entire transverse direction QR. The film web FB is delivered from the nozzle slit 112 in the production direction PR. In order to adjust the thickness profile of the film web FB, a plurality of adjustment mechanisms 120 in the form of heat-sensitive pins are provided here.

[0033] figure 2 A heat-sensitive pin, shown as an adjustment mechanism 120 , acts on the nozzle lip above the nozzle slit 112 from above. Thermal expansion of the adjustment mechanism 120, through the application of thermal energy, reduces the nozzle gap 112, resulting in a corresponding reduction in the strength or thickness profile of the film web. figure 1 The control device 10 is shown on the left side of the flat film machine 100 . In this case, the calibration position KP can now be predetermined by means of the presetting module. Based on this, a corresponding co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com