Automatic adhesive tearing and discharging mechanism for adhesive tape pasting type material belt

A sticky and tape technology, applied in the direction of unsealing, packaging, cutting and unsealing of objects, which can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

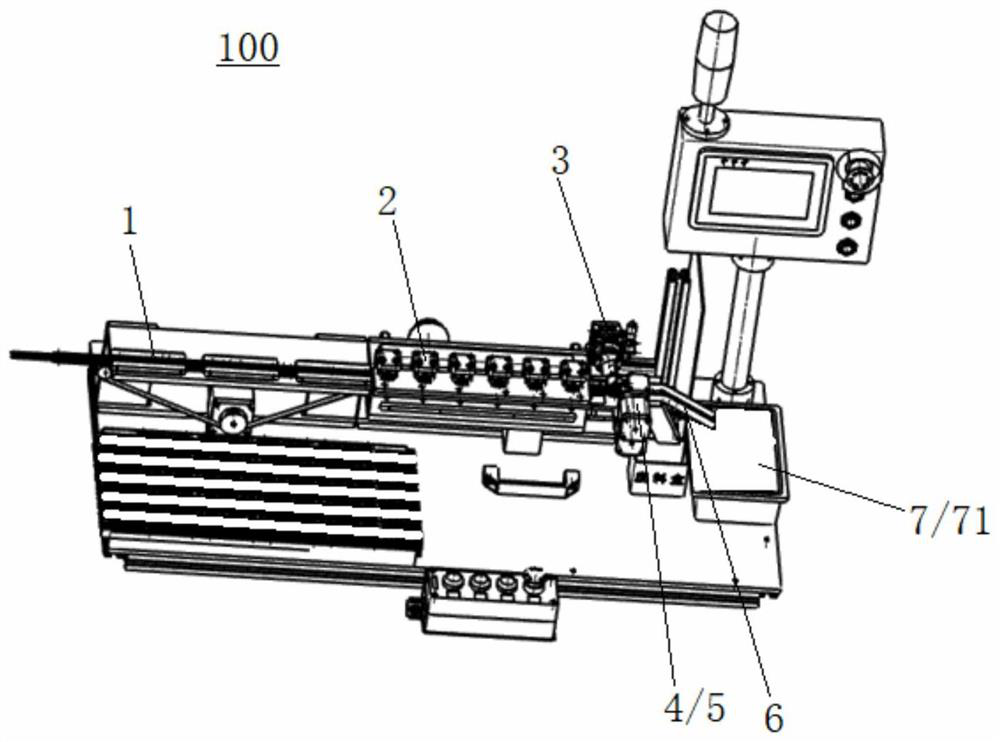

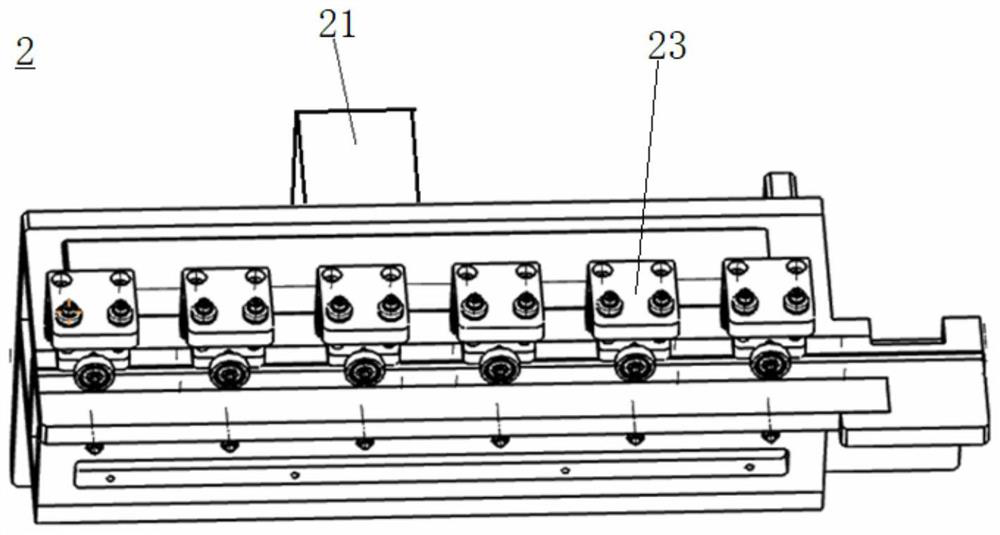

[0036] Please refer to Figure 1-Figure 8 , the present embodiment is an automatic glue tearing and unloading mechanism 100 for adhesive tape sticking type material belt, which includes a feeding unit 1, a material belt leveling unit 2 docked with the material loading unit 1, and is arranged at the end of the material belt leveling unit 2 and The peeling unit 3 that separates the tape on the upper and lower surfaces of the tape, the lower peeling unit 4 that holds the tape on the lower surface of the tape and transports it forward, and the upper tearing unit that holds the tape on the upper surface of the tape and feeds forward 5. The waste collection unit 6 that accepts the adhesive tape output from the lower glue removal unit 4 and the upper glue tear unit 5 and collects it, and the carrier tape receiving unit 7 located behind the lower glue tear unit 4 and the upper glue tear unit 5 that accepts the carrier tape.

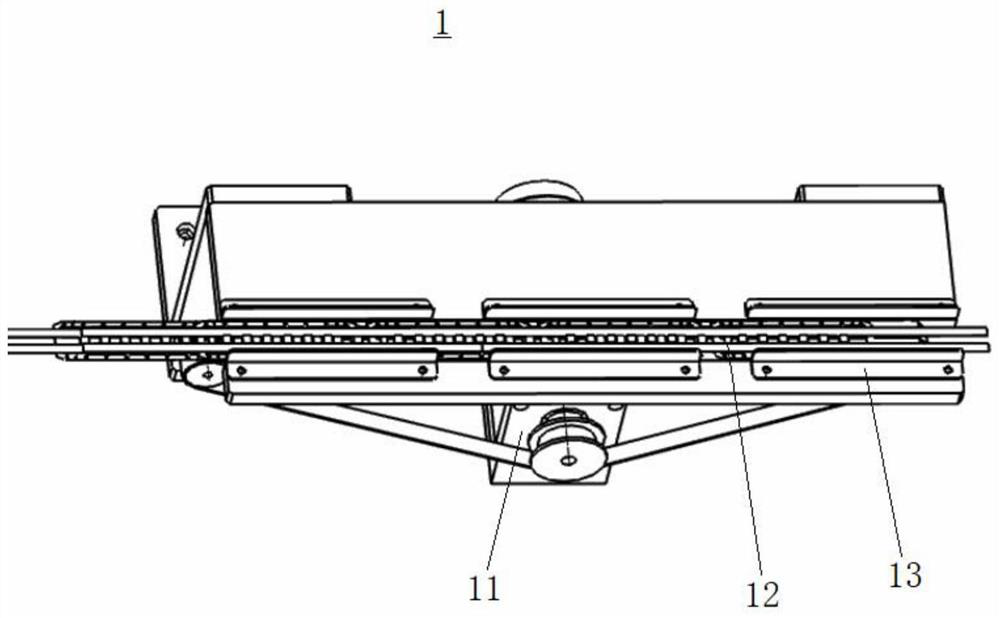

[0037] The feeding unit 1 includes a first motor 11 , a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com