A method for extracting 1,3-propanediol in fermentation broth with alcohol mixed solvent

A mixed solvent and propylene glycol technology, applied in the field of biological engineering, can solve the problems of increasing the complexity of the separation process, energy consumption, and large loss of extractant, and achieve the effects of reducing losses and reducing separation pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026](1) Preparation of 1,3-propanediol fermentation broth: 1,3-propanediol fermentation broth is obtained by batch fed-batch fermentation by Clostridium butyricum, fermentation culture conditions: inoculum size 10% (v / v), 1h before inoculation Nitrogen was blown, the fermentation temperature was 37°C, the fermentation stirring speed was 250r / min, and 5mol / L NaOH solution was used to adjust the pH to maintain neutrality during the fermentation process. The initial glycerol concentration was 80g / L, and the feed was fed in two pulses. When the glycerin concentration dropped below 15g / L, the feed was fed to 80g / L. Fermentation was terminated when glycerol was no longer consumed. Clostridium butyricum is a commercially available Clostridium butyricum commonly used in the art for fermentative production of 1,3-propanediol.

[0027] (2) Preparation of 1,3-propanediol supernatant: use a conventional centrifuge or a membrane separation system to remove bacteria from the 1,3-propaned...

Embodiment 1

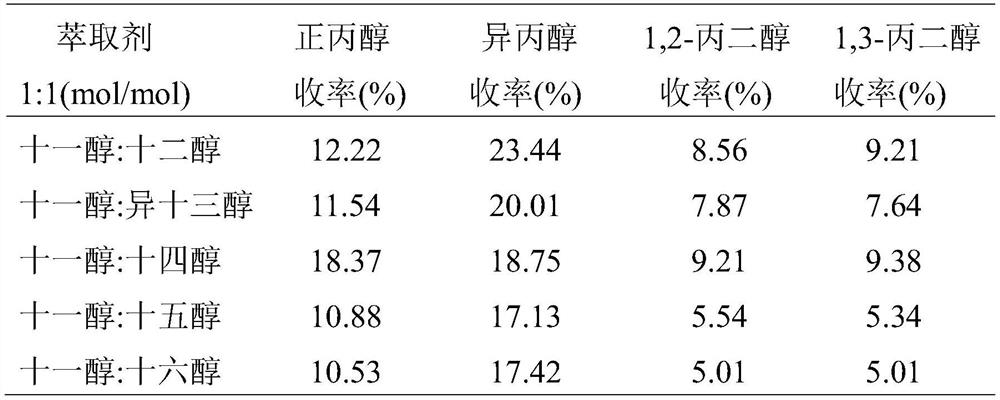

[0036] Example 1 The extraction effect of two kinds of alcohol mixed solvents based on undecyl alcohol composition

[0037] The materials used in this example are simulated solutions prepared with n-propanol, isopropanol, 1,2-propanediol, and 1,3-propanediol standard products respectively, with a concentration of 100 g / L. The extractant is prepared by mixing undecanol with dodecanol, isotridecanol, tetradecyl alcohol, pentadecyl alcohol and hexadecanol at 60°C at a ratio of 1:1 (mol / mol). At 60°C, mix 10mL of extractant with 10mL of n-propanol, isopropanol, 1,2-propanediol, and 1,3-propanediol simulation solution, shake well for 1min, and let stand for 5h. The content was determined by gas chromatography, and the yield was calculated. The results are shown in Table 1.

[0038] Table 1. Extraction results of n-propanol, isopropanol, 1,2-propanediol and 1,3-propanediol

[0039]

[0040] For extractants with different components, the greater the total number of C atoms of th...

Embodiment 2

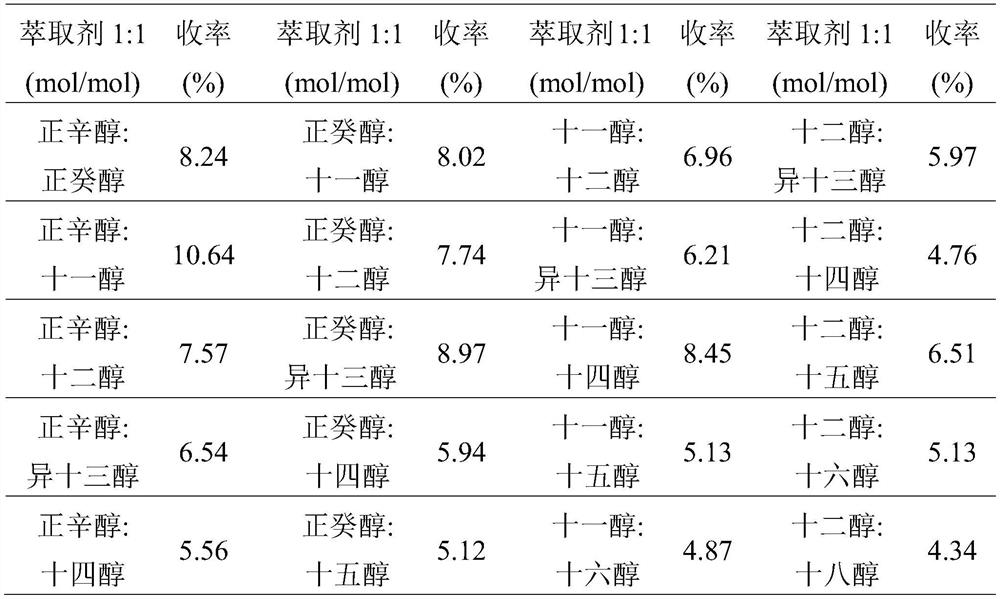

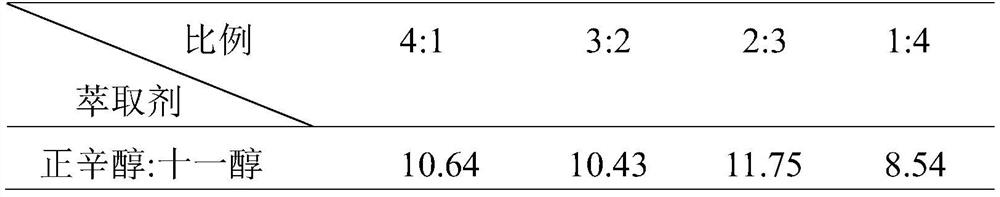

[0041] Embodiment 2 Two kinds of alcohols mixed solvents are to the extraction effect of 1,3-propanediol

[0042] The material used in this example is a simulated solution prepared with a 1,3-propanediol standard product, with a concentration of 100 g / L. The extractant is a mixed alcohol solvent of four series: (1) n-octanol is mixed with n-decyl alcohol, undecyl alcohol, dodecyl alcohol, isotridecanol, and myristyl alcohol respectively; Mixture of monoalcohol, lauryl alcohol, isotridecanol, tetradecyl alcohol and pentadecyl alcohol; (3) undecyl alcohol mixed with dodecyl alcohol, isotridecanol, tetradecyl alcohol, pentadecyl alcohol and cetyl alcohol respectively (4) Dodecyl alcohol is mixed with isotridecanol, tetradecyl alcohol, pentadecyl alcohol, cetyl alcohol, and stearyl alcohol respectively. The mixing condition is 60°C, and the two alcohols are mixed uniformly at a ratio of 1:1 (mol / mol). At 60°C, take 10mL of extractant and 10mL of 1,3-propanediol simulated solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com