Expansion rivet

A technology of expanding rivets and pins, which is applied in the direction of rivets, pins, screws, etc., and can solve problems such as creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Different figures and components in the same figure are not necessarily shown to the same scale. In all figures, the same parts have the same reference numerals.

[0036] The terms used in this specification should under no circumstances be interpreted in a limiting or restrictive manner, merely as it is used in connection with the detailed description of certain embodiments of the invention.

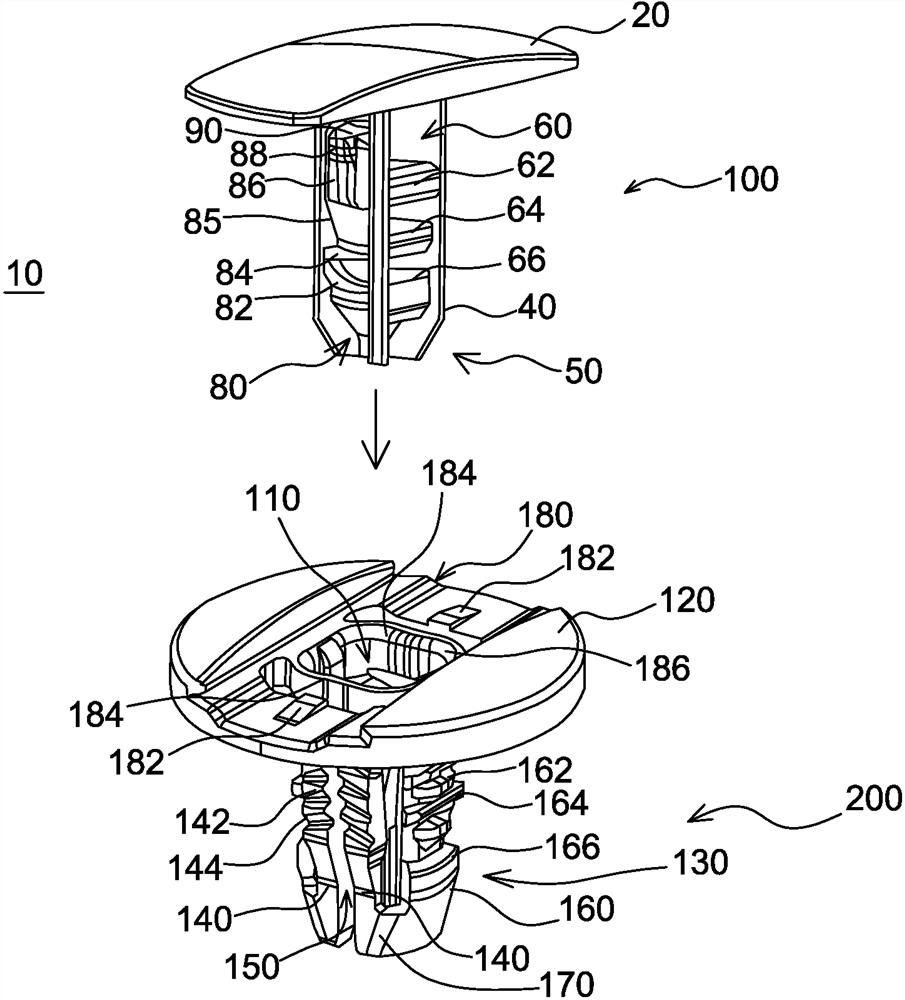

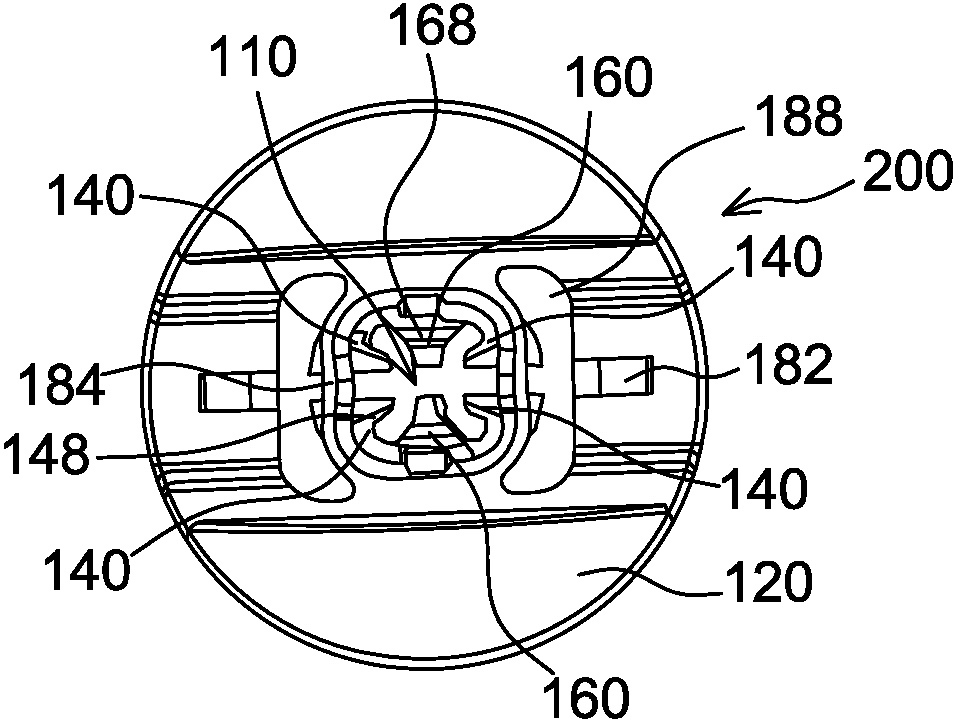

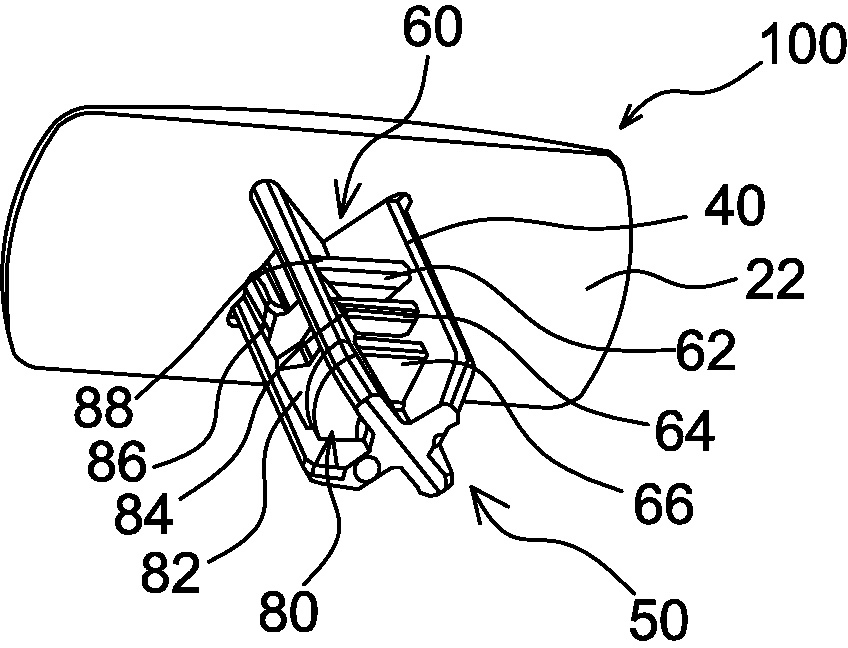

[0037] figure 1 An exploded view of the expansion rivet 10 according to the invention is shown, which essentially consists of a body 200 and a pin 100 . For illustrative purposes only, such as Figure 4D As shown, the device 10 may be used to fasten a first structure 300, such as an instrument panel, to a second structure 400, such as a vehicle body panel, as will be described in detail below. The first structure and the second structure are respectively provided with through holes to allow such fastening using the expansion rivets 10 .

[0038] The two basic parts 100, 200 o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap