A non-contact excitation device for mems microstructure based on shock wave

A kind of excitation device, non-contact technology, applied in the direction of microstructure device, microstructure technology, etc., can solve the problems of difficult dynamic characteristic parameters of microstructure, achieve the effect of good excitation effect, improve vibration excitation ability, and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

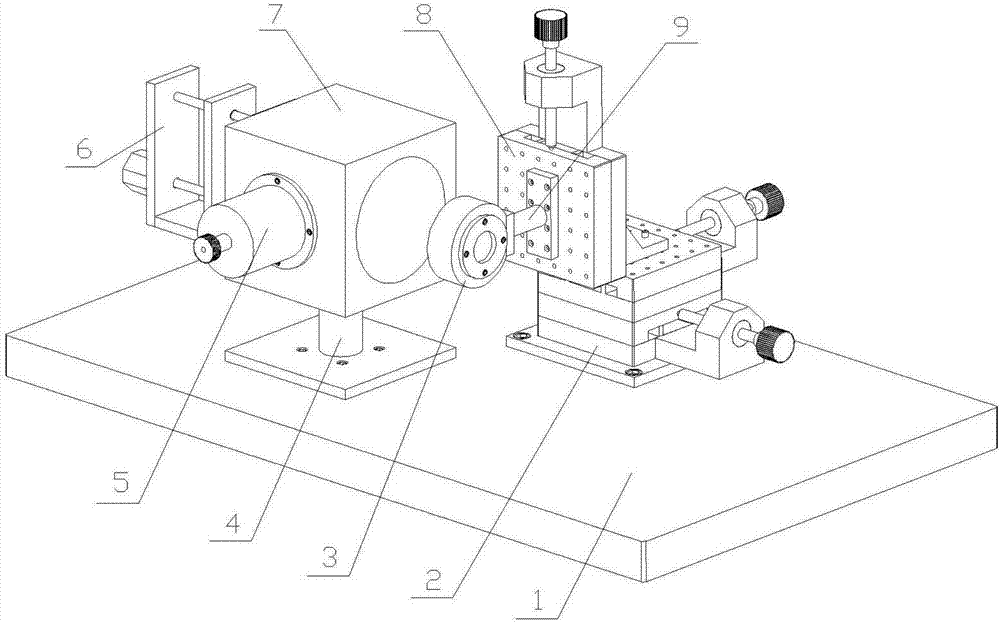

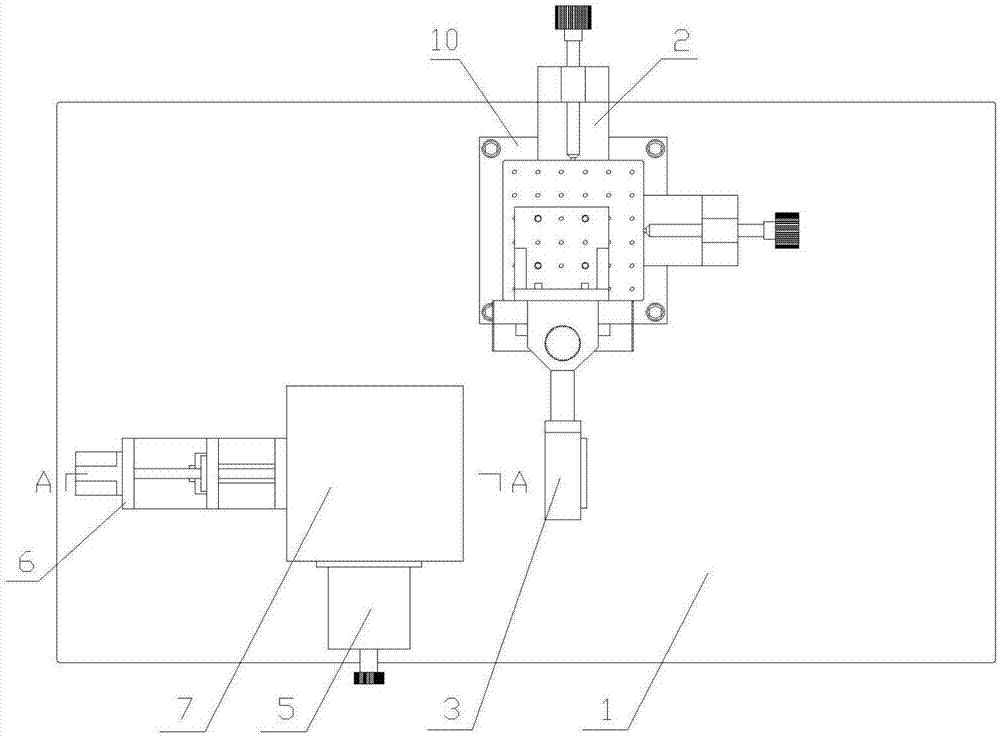

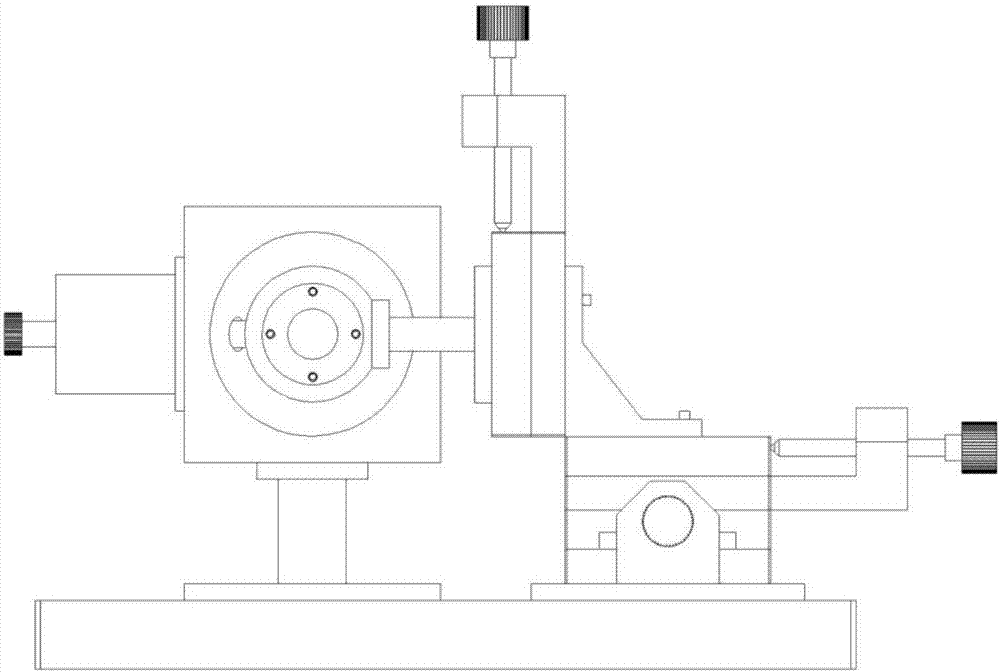

[0030] like Figure 1-Figure 3 As shown, a shock-based MEMS microstructure non-contact excitation device related to the present invention includes a substrate 1, on which a manual three-axis translation platform 2 and a support 4 are arranged, and the manual three-axis translation platform 2 is installed on a bottom plate 10, which is fixed on the base plate 1 by screws. A microstructure unit 3 is provided on the Z-axis slide plate 8 of the manual three-axis displacement table 2;

[0031] like Figure 7-Figure 9 As shown, the microstructure unit 3 includes a mounting sleeve 301 installed on the Z-axis slide plate 8 through a horizontal support 9, and a stepped first mounting hole is provided in the mounting sleeve 301. In the first mounting hole The inner bottom is equipped with a MEMS microstructure 305 through a microstructure mounting plate 307; A through hole corresponding to the small hole at the bottom of the first installation hole is provided on the upper surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com