Rust-proof and corrosion-resistant electrostatic powder spraying device for refrigerator shell

A technology of electrostatic powder and spraying device, applied in electrostatic spraying device, spraying device, liquid spraying equipment, etc., can solve the problems of low efficiency and increase labor cost, and achieve the effect of simple operation, novel design, convenient automatic flanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

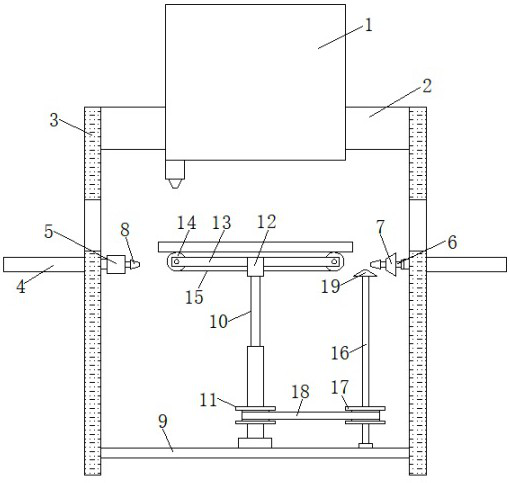

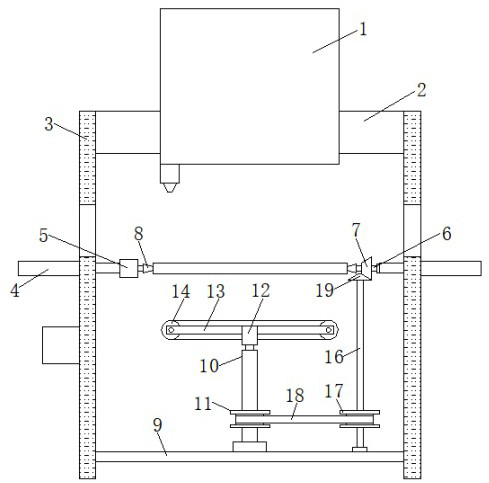

[0027] refer to Figure 1-3 : An anti-rust and anti-corrosion electrostatic powder spraying device for a refrigerator shell, comprising a spraying box 1, two sides of the spraying box 1 are fixedly connected with support plates 3, and the sides of the two support plates 3 away from each other are provided with a clamping turning mechanism, The bottom between the two support plates 3 is fixedly connected with a supporting plate 9, and the top of the supporting plate 9 is rotatably connected with a second push rod motor 10, and the top of the second push rod motor 10 is fixedly connected with a transmission mechanism, and the second push rod motor 10 is provided with transmission mechanism.

[0028] In the present invention, the turning mechanism includes a first push rod motor 4 fixedly connected to the support plate 3, the output shaft of the first push rod motor 4 on the left side is fixedly connected with a drive motor 5, and the output shaft of the first push rod motor 4 on...

Embodiment 2

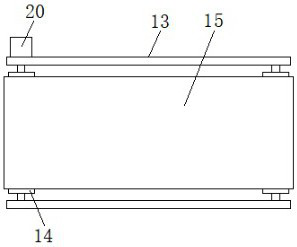

[0031] refer to figure 2 , Figure 4-6 : A kind of anti-rust and anti-corrosion electrostatic powder coating device for refrigerator shells. In the present invention, the transmission mechanism includes a fixed plate 12 fixedly connected with the output shaft of the second push rod motor 10, and two splints 13 are fixedly connected on the fixed plate 12. , there are two transmission rollers 14 rotatably connected between the two splints 13, the outside of the transmission rollers 14 is provided with a conveyor belt 15, and a servo motor 20 is fixedly connected to the left side of the back splint 13; the servo motor 20 can drive the transmission roller 14 to rotate , the transmission roller 14 drives the transmission belt 15 to rotate, so that feeding and spraying can be realized.

[0032] In the present invention, the transmission mechanism includes a first pulley 11 fixedly sleeved on the outside of the second push rod motor 10, the right side of the first pulley 11 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com