A tilting mechanism, carriage and railway self-overturning vehicle

A technology of tipping mechanism and car box, which is applied to railway car body parts, dump trucks, transport passenger cars, etc., can solve the problems of inflexible dumping of goods and classification, inconsistent turning angles, and reduced unloading efficiency, so as to save transportation capacity and improve the efficiency of unloading. The effect of unloading rate and improving unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

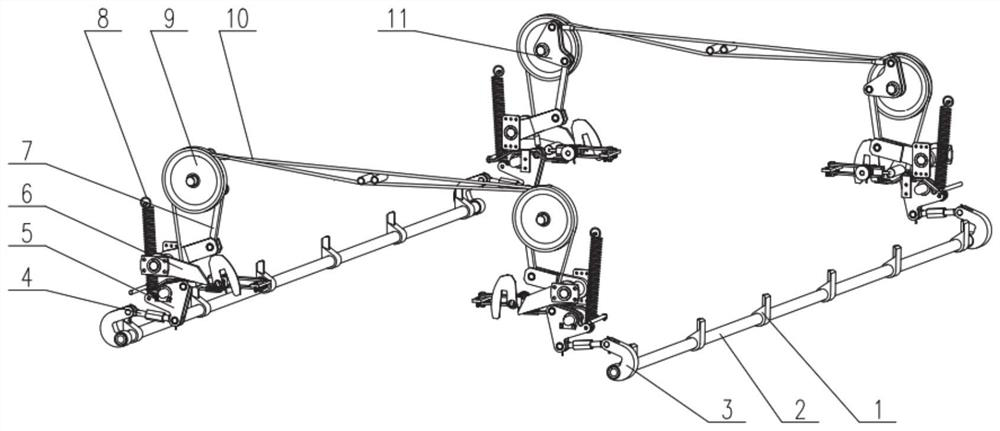

[0051] In this embodiment, a kind of railway self-rolling car box is provided, and the car box includes a box structure, side door components 15 are arranged on both sides of the box structure, end door components 13 are arranged at the end of the box structure, the side door components are fixed by steel beams at the top, and It can be opened and closed but the rotation angle is limited to prevent the side door from being washed away by the cargo during the tipping process.

[0052] The side door can be self-limited to limit the turning range.

[0053] The end door is composed of a tilting mechanism installation seat plate for fixing the tilting mechanism as described in Embodiment 1.

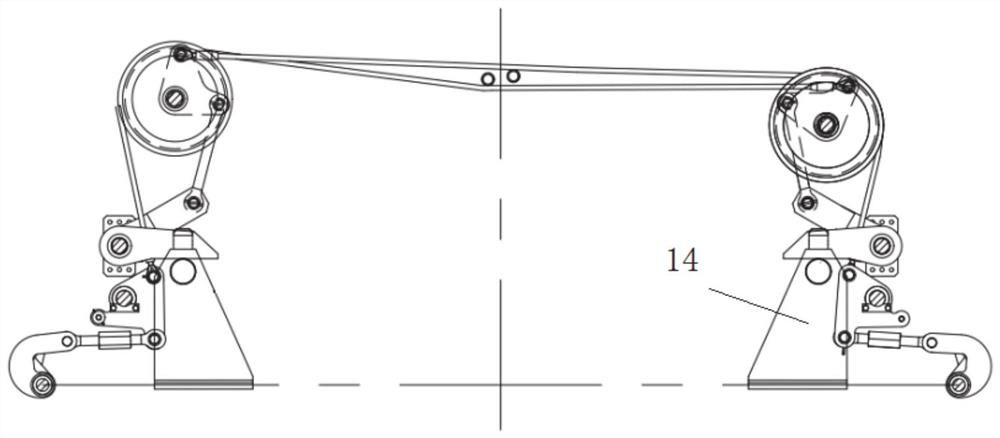

[0054] Lock seats 14 are arranged on both sides of the end door composition, and lock shafts are arranged on the lock seats. When the carriage does not tip over, the lock bar formed by the lock door pressing bar overlaps and is compressed on the lock shaft, and the lock seat and the lock door ...

Embodiment 3

[0058] In this embodiment, a railway self-dumping car is proposed, which includes a car body, and the car body is provided with a car box as described in the second embodiment.

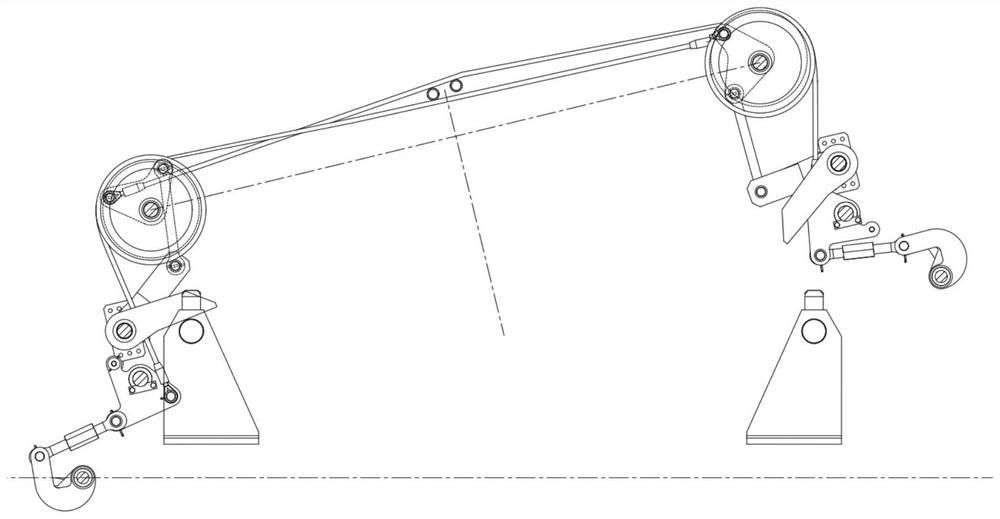

[0059] In this embodiment, each self-tipping vehicle is provided with two sets of carriages, and each set of carriages is equipped with the same tilting mechanism that operates independently, so that the tilting operation can be performed asynchronously.

[0060] The car body comprises an underframe, the carriage is arranged on the top of the underframe, and the outside of the side beam of the underframe is provided with a shroud 16, which is correspondingly arranged below the side door, and the shroud is arranged obliquely, that is, the shroud is arranged with the vertical direction. With a fixed angle, the shroud is used to dump goods when the vehicle is in overturning operation, improving the discharge rate of fine ore or slag, and preventing it from entering and accumulating in the lower chassis an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com