Two-way usable pipeline sealing device

A pipeline sealing and concave technology, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, passing components, etc., can solve the problems of difficult installation and disassembly of pipeline sealing devices, and achieve simple structure, good sealing work and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

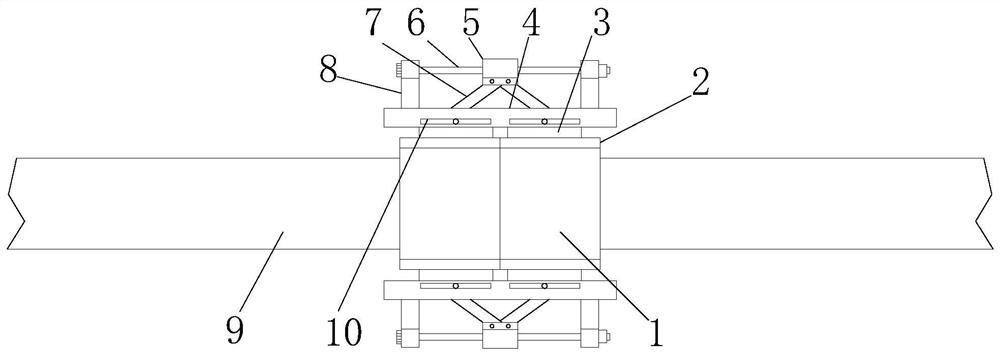

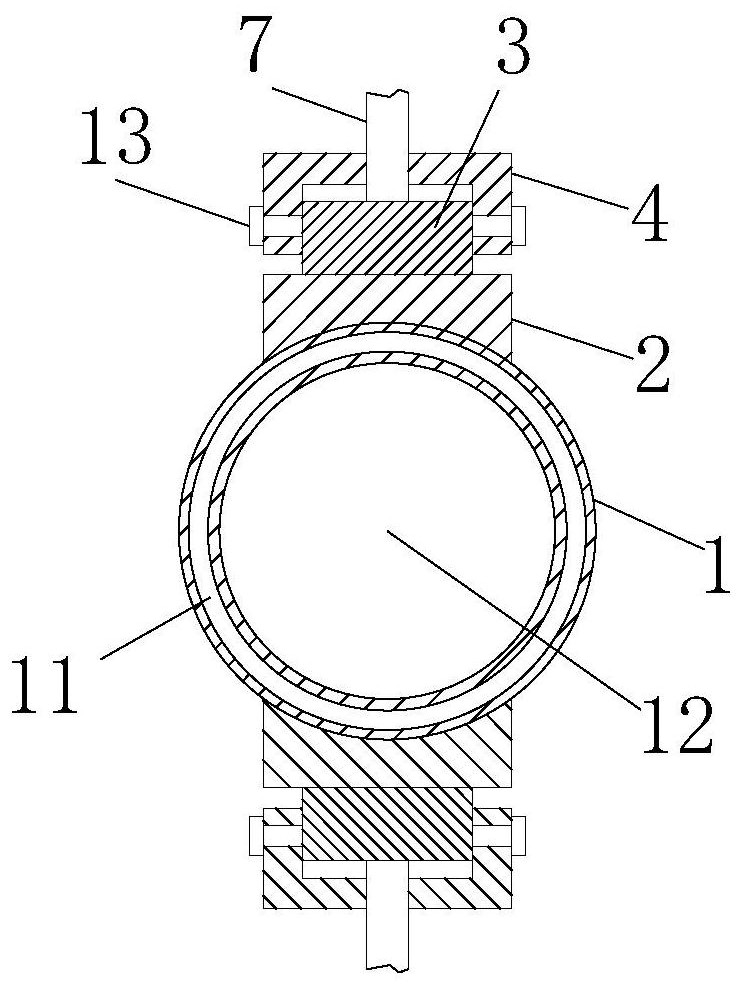

[0019] see Figure 1-2 , the present invention provides a two-way pipeline sealing device, comprising two discs 1, concave blocks 4 and limit blocks 5, two discs 1 are provided with threaded holes 12 penetrating through the end faces of both sides, two A connecting block 2 is fixedly installed on the circumferential surface of the disk 1, and a slider 3 is fixedly installed on the tops of the two connecting blocks 2, and the two sliders 3 are all slidably installed in the groove of the concave block 4. The top of the slide block 3 is hinged with drive rods 7, and the sides away from the concave block 4 on the two drive rods 7 are all hinged at the bottom of the limit block 5, and the limit block 5 is located above the concave block 4, and the concave The shaped block 4 is provided with openings for the movement of the two driving rods 7 , and the concave block 4 is provided with a limiting mechanism for fixing the position of the limiting block 5 .

[0020] In this embodiment...

Embodiment 2

[0025] see Figure 1-2 , this embodiment is further optimized on the basis of Embodiment 1, specifically, the limit mechanism includes a fixed plate 8 symmetrically arranged on the top of the concave block 4 and located on both sides of the limit block 5, two fixed plates 8 are provided with sockets, and the limit mechanism also includes screws 6 that are compatible with the sockets. The inside of the sockets is provided with threads that are compatible with the screws 6. The limit mechanism includes through holes that are opened on the limit block 5. The screws 6 pass through the through holes and are threadedly connected with the two fixing plates 8 respectively.

[0026] By using the screw 6 to pass through the limit block 5, and threadedly connected with the two fixing plates 8, and at the same time hinge the driving rod 7 under the limit block 5, so that the transverse force that affects the sealing between the two pipes 9 is transformed For the downward longitudinal for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com