Small-diameter micro-resistivity scanning imager

A technology of micro-resistivity and scanning imaging, which is applied in the directions of measurement, borehole/well components, earthwork drilling and production, etc. It can solve the problems of poor heat dissipation performance of the acquisition module, short usable time, and low logging efficiency, so as to improve the logging efficiency. Well efficiency, low risk of fluid leakage and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following is attached Figure 1-10 The application is described in further detail.

[0062] The embodiment of the present application discloses a small-diameter micro-resistivity scanning imager.

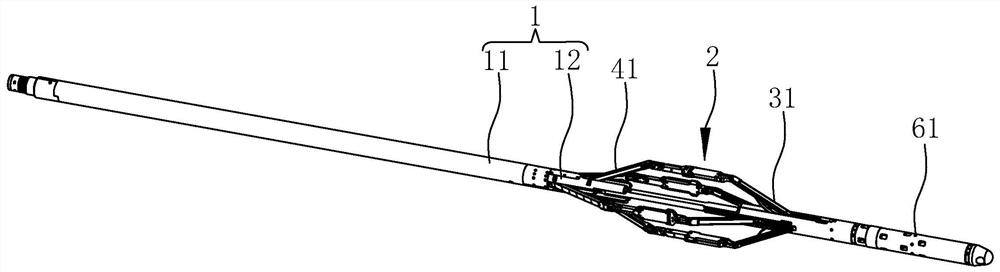

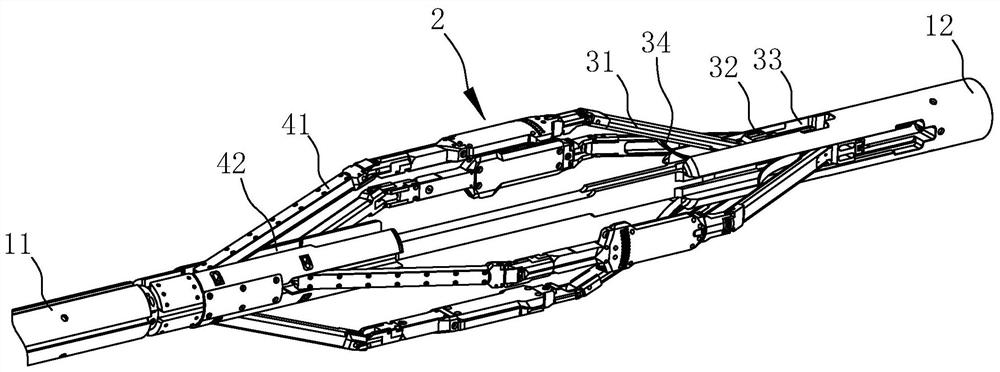

[0063] refer to figure 1 and figure 2 , the small-diameter micro-resistivity scanning imager includes a main rod 1 and several acquisition modules 2 . The main rod 1 includes a first rod 11 and a second rod 12 , the first rod 11 is a cylinder, and the second rod 12 extends into the first rod 11 and is fixedly connected with the first rod 11 . In this embodiment, four collection modules 2 are provided, and the four collection modules 2 are arranged circumferentially around the second rod 12, and the collection modules 2 are staggered in the axial direction of the second rod 12, and each collection module 2 Both are parallel to the main rod 1.

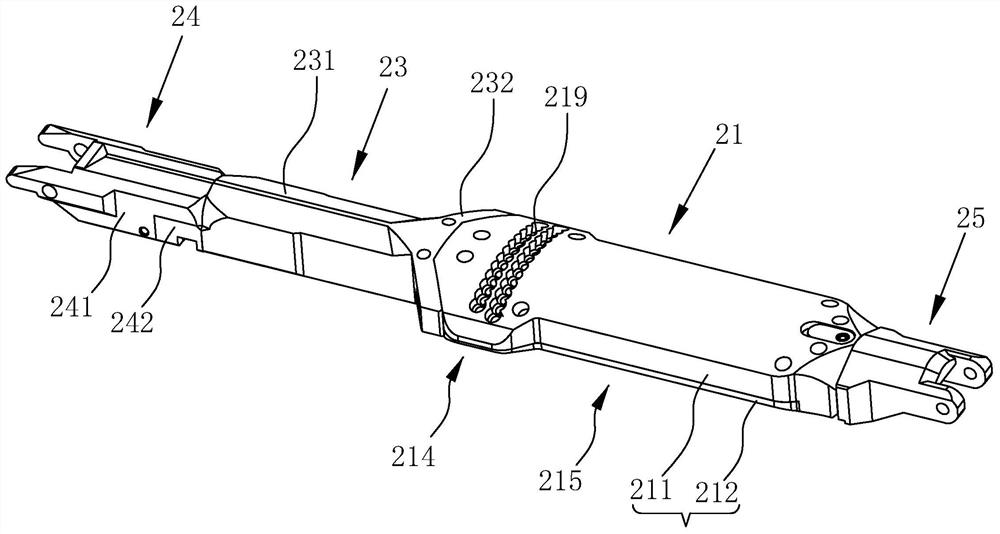

[0064] refer to image 3 and Figure 4 , the collection module 2 includes a collection plate 21 , a main arm connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com