Near-suction-type range hood and control method of range hood

A range hood and near-suction technology, which is applied in the control field of near-suction range hoods and range hoods, can solve the problems of large fume escape risk, fume escape, and inability to dynamically adjust, so as to improve the effect of range hood, Good smoke holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

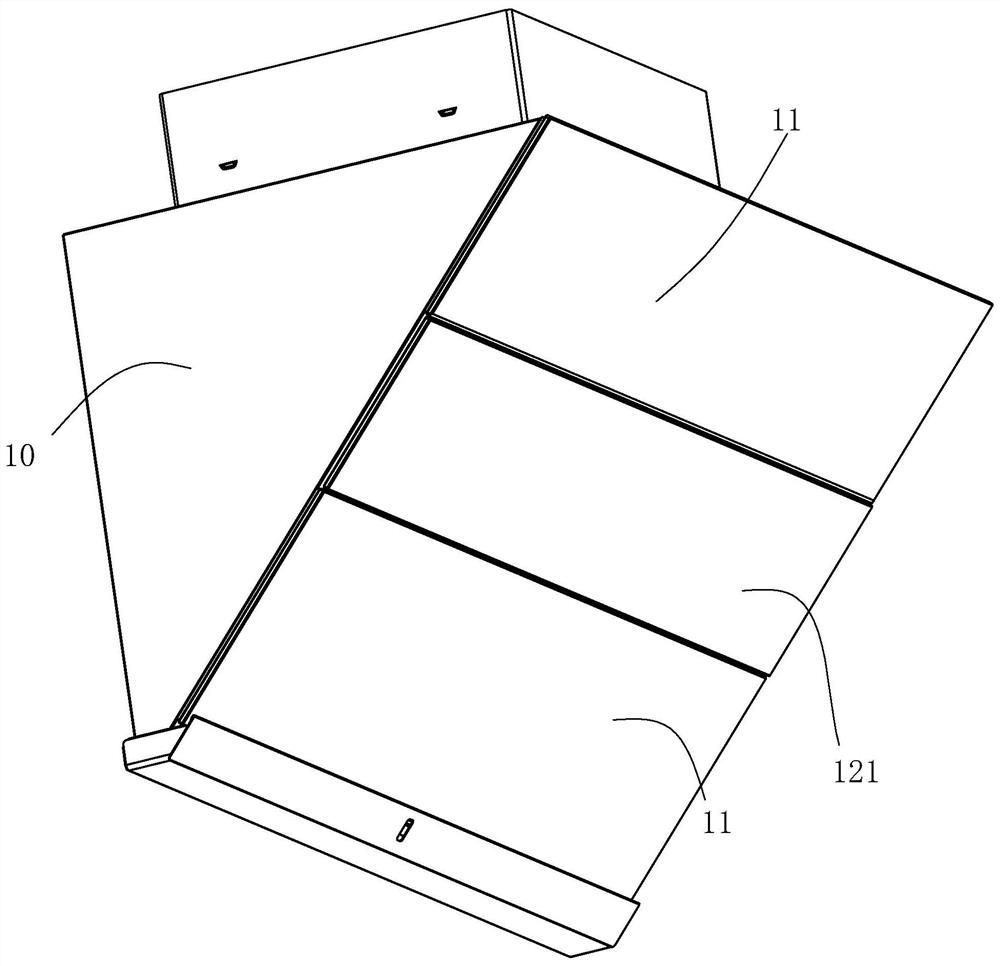

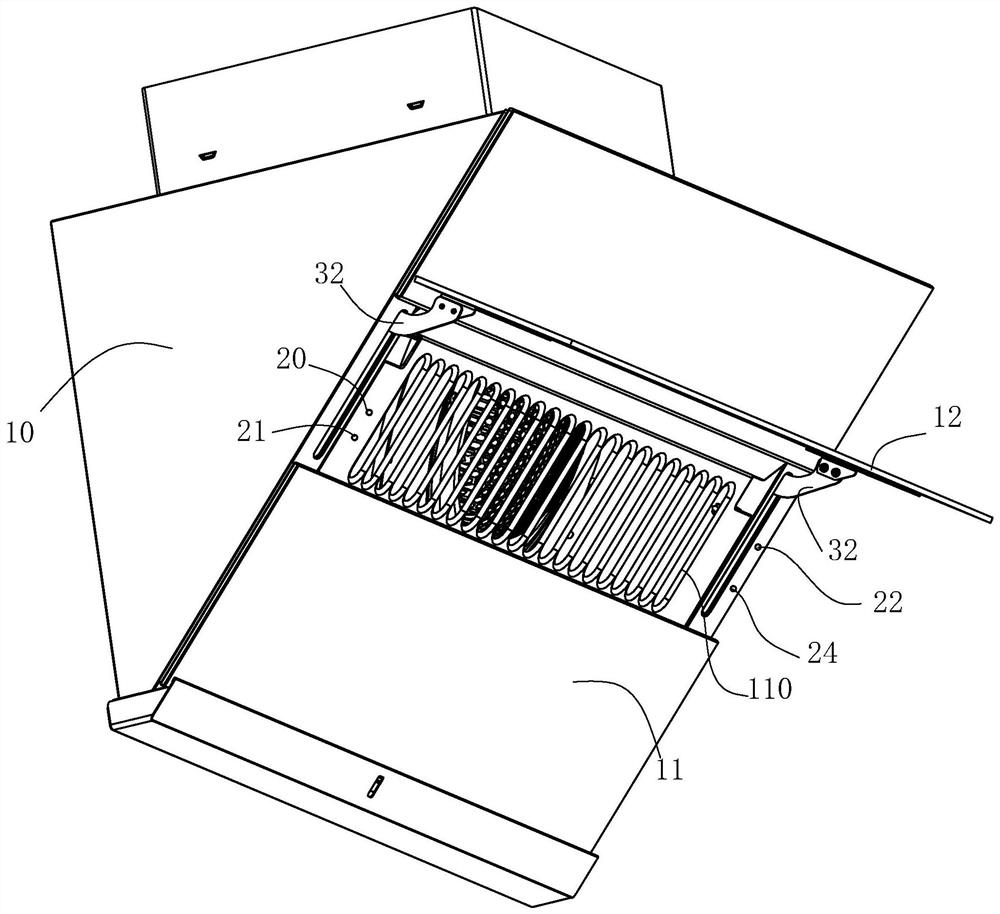

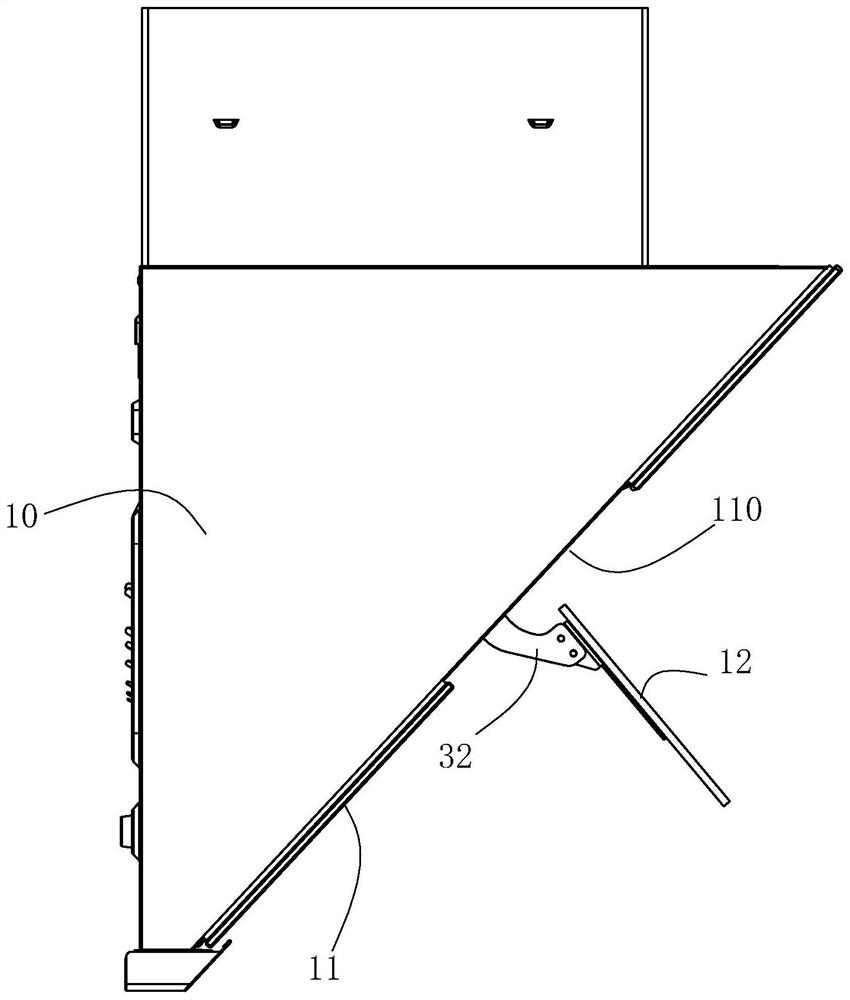

[0062] see Figure 1-Figure 9 , a near-suction range hood includes a housing 10, an air inlet plate 11, a smoke baffle 12, a first drive mechanism, a connecting rod transmission mechanism, a second drive mechanism, a first detection device, a second detection device and a sensor Detection module 20.

[0063] see figure 1 and figure 2 , the front side of the housing 10 has an opening, and the plane where the opening is located is an inclined surface that slopes downward from front to back. An air inlet plate 11 is provided at the position of the above opening, the air inlet plate is a rectangular plate, and an air inlet 110 is opened on the air inlet plate 11 . The plane where the above-mentioned air inlet plate 11 is located and the plane where the air inlet 110 on the air inlet plate 11 is located are also inclined surfaces that incline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com