Exhaust throttler for plane cascade flow simulation device

A cascade flow and simulation device technology, applied in the direction of measuring devices, engine testing, instruments, etc., can solve the problems of increased test error, reflection of exhaust flow, limited noise reduction effect, etc., to change the test Reynolds number, Wide airflow angle range and obvious noise reduction effect

Inactive Publication Date: 2021-06-15

中国空气动力研究与发展中心空天技术研究所

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the exhaust gas collection components used in the plane cascade flow simulation device at home and abroad have the following disadvantages: 1. Most of them use bell-shaped opening exhaust gas collection devices, and the noise reduction effect is limited; 2. To meet the large outlet airflow angle of the turbine cascade test Exhaust collection, the size of the bell mouth expands drastically, and the manufacturing cost will increase. Otherwise, it will be difficult to cover the exhaust collection of all cascade tests, and the exhaust collection effect is not ideal; 3. The bell mouth exhaust collection device is in some cases It may also cause the reflection of the exhaust to the incoming flow, thereby affecting the flow field in front of the test cascade, resulting in an increase in the test error; 4. The opening exhaust collection device cannot be equipped with a back pressure regulating valve, nor can it realize the auxiliary adjustment of the back pressure of the test section

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

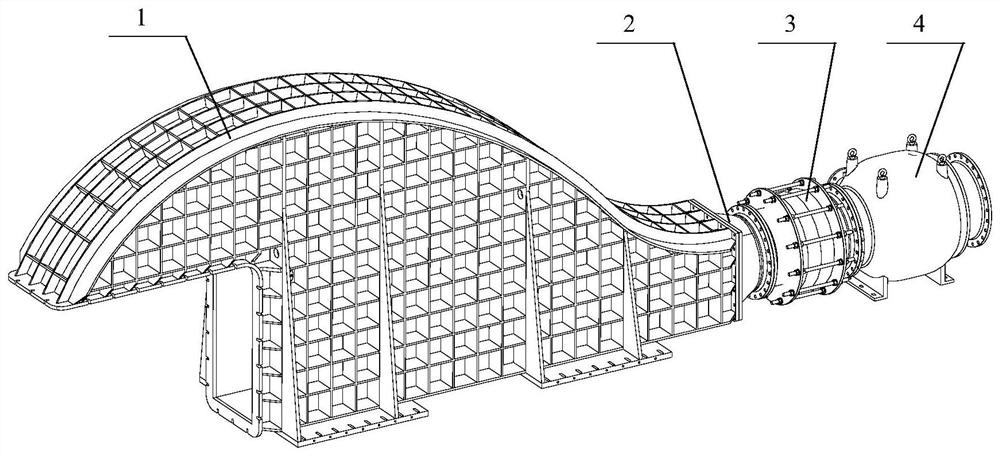

[0020] The transverse length of the inlet section of the exhaust restrictor of this embodiment is 2284 mm, the height is 1903 mm, and the width is 800 mm; the outlet section height is 850 mm, and the width is 800 mm; The diameter of the expansion joint 3 is 800mm, the diameter of the exhaust pressure regulating valve pipe 4 is 800mm, and the total length of the exhaust restrictor is 12430mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an exhaust throttler for a plane cascade flow simulation device. The exhaust throttler sequentially comprises an exhaust collector, a square-to-round part, an expansion joint and an exhaust pressure regulating valve from front to back in the airflow direction; the front end of the exhaust collector is clamped on the plane cascade test chamber to collect outlet airflow of the plane cascade test chamber, the outlet airflow is rectified through the exhaust collector and then guided into a subsequent exhaust system, and the ratio of the area of the maximum cross section of the inlet of the exhaust collector to the area of an outlet is (4-10):1. The exhaust throttler is simple in structure, not only can realize outlet airflow rectification, exhaust resistance reduction and exhaust noise reduction of various plane cascade tests and prevent the interference of incoming flow reflection of exhaust to a flow field in front of a test cascade, but also can assist in adjusting the test back pressure of a test section in a plane cascade test cabin and fulfill the aim of changing the test Reynolds number.

Description

technical field [0001] The invention belongs to the field of aero-engine basic research test equipment, and in particular relates to an exhaust restrictor used for a planar cascade flow simulation device. Background technique [0002] Aviation turbines (including fans / compressors and turbines) and gas turbines are key components for maintaining thermal cycles and generating thrust, and the aerodynamic shape of their rotor / stator blades determines the aerodynamic performance of aviation turbines and gas turbines. In order to design high-performance aerojet engines and gas turbines, it is necessary to study the design method and flow characteristics of the turbine at the cascade (two-dimensional airfoil) level. In order to conduct experimental research on the aerodynamic characteristics of cascade passage flow under real flight conditions on the ground, it is necessary to build ground equipment that can simulate parameters such as the Mach number and Reynolds number of the cas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M15/02

CPCG01M15/02

Inventor 任思源魏巍马护生时培杰陈峰宗有海李学臣黄康李聪叶敏谭锡容江辉

Owner 中国空气动力研究与发展中心空天技术研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com