Hand crimp tool having wire inserter

一种压接工具、插入器的技术,应用在制造工具、线路/集电器零部件、连接等方向,能够解决组件变化、无法使用、导线位置不一致等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

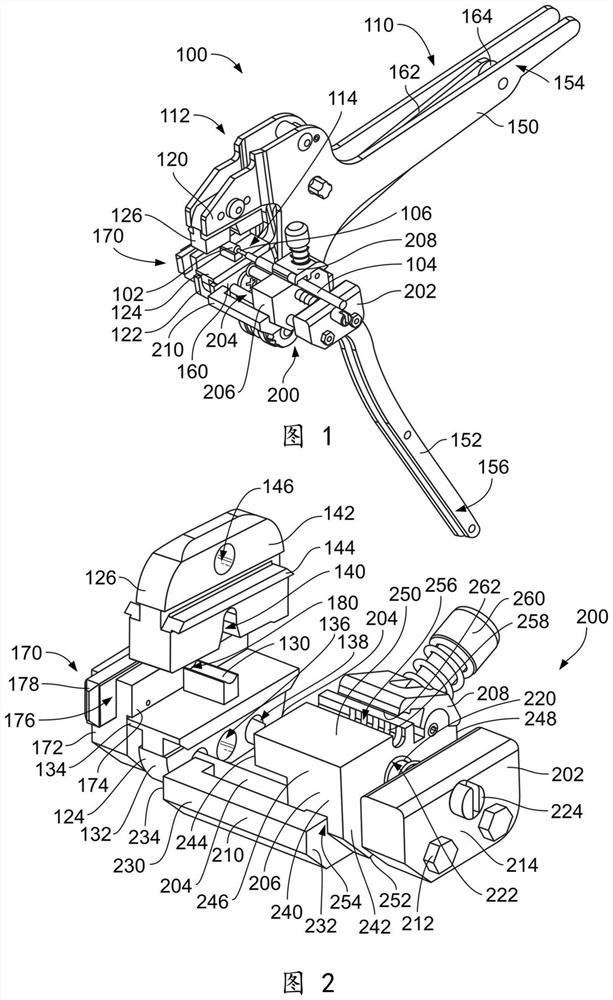

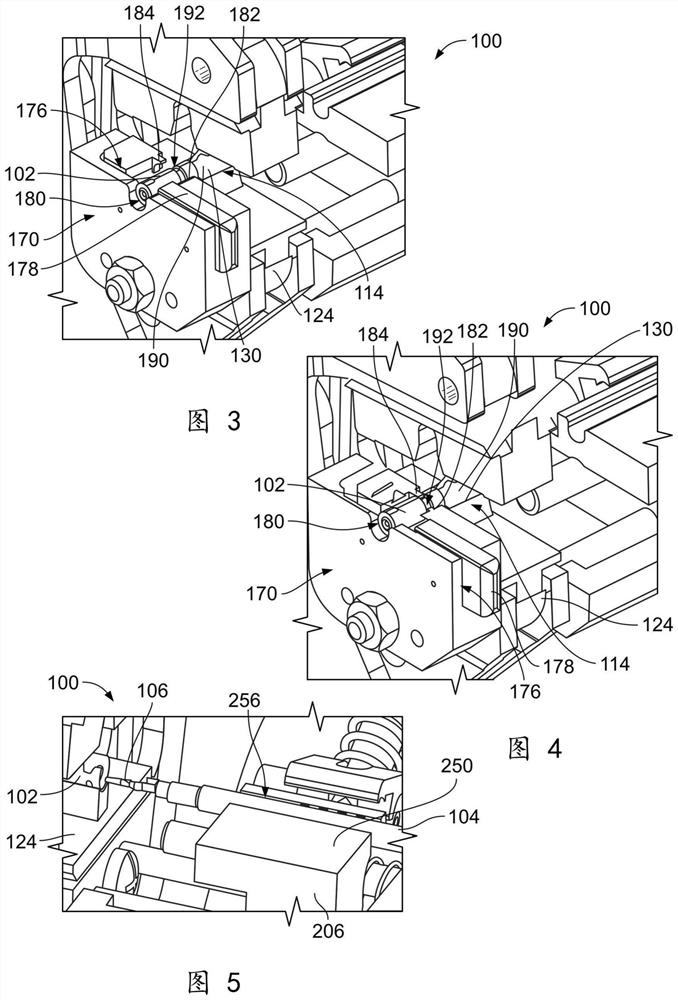

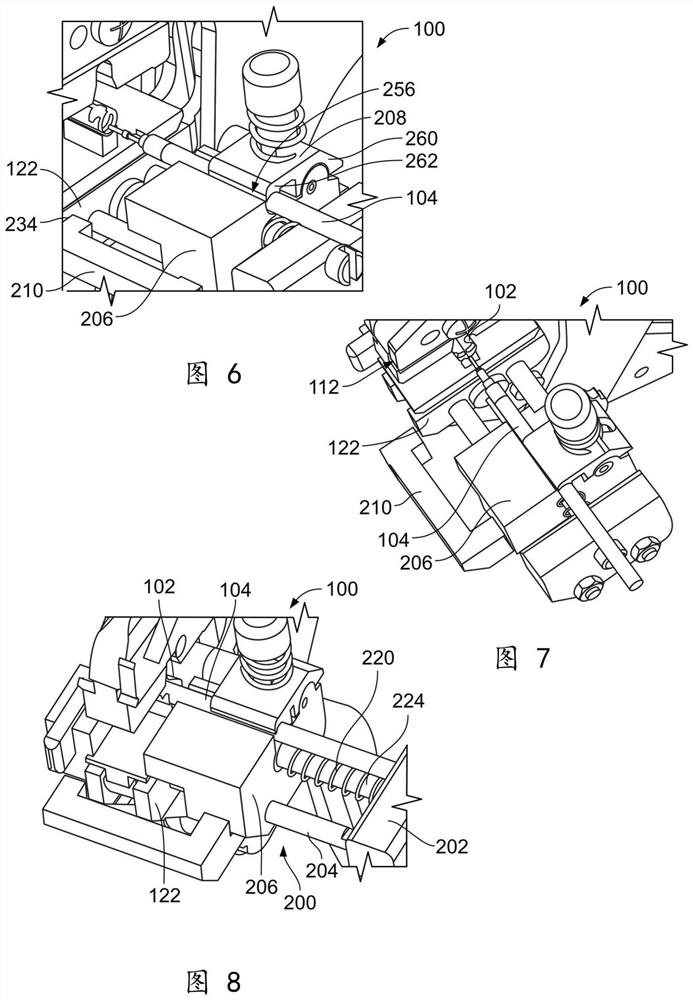

[0018] figure 1 is a perspective view of a hand crimp tool 100 according to an exemplary embodiment. The hand crimp tool 100 is used to manually crimp a terminal 102 to a wire 104 . For example, the hand crimp tool 100 may be opened and closed during the crimping process to crimp the terminal 102 to the wire 104 . The manual crimping tool 100 is manually actuated by an operator to close the manual crimping tool 100 during the crimping process. In the exemplary embodiment, the contacts 106 are disposed at the ends of the wires 104 and are loaded into the terminals 102 along with the wires 104 . Terminals 102 are crimped onto wires 104 around contacts 106 . For example, contact 106 defines a center contact that terminates to a center conductor of wire 104 , while terminal 102 defines an outer contact that terminates to a shield of wire 104 . In other various embodiments, the wire 104 is provided without the contact 106 , and the terminal 102 is terminated to the center condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com