Overhead door mechanism of wall cupboard and wall cupboard

A hanging cabinet and flip door technology, applied in the field of hanging cabinets, can solve the problems that the open area cannot meet the needs of users, the maximum height of the flip door cannot meet the needs of users, etc., to improve the user experience, simple structure, and increase the height of the flip Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

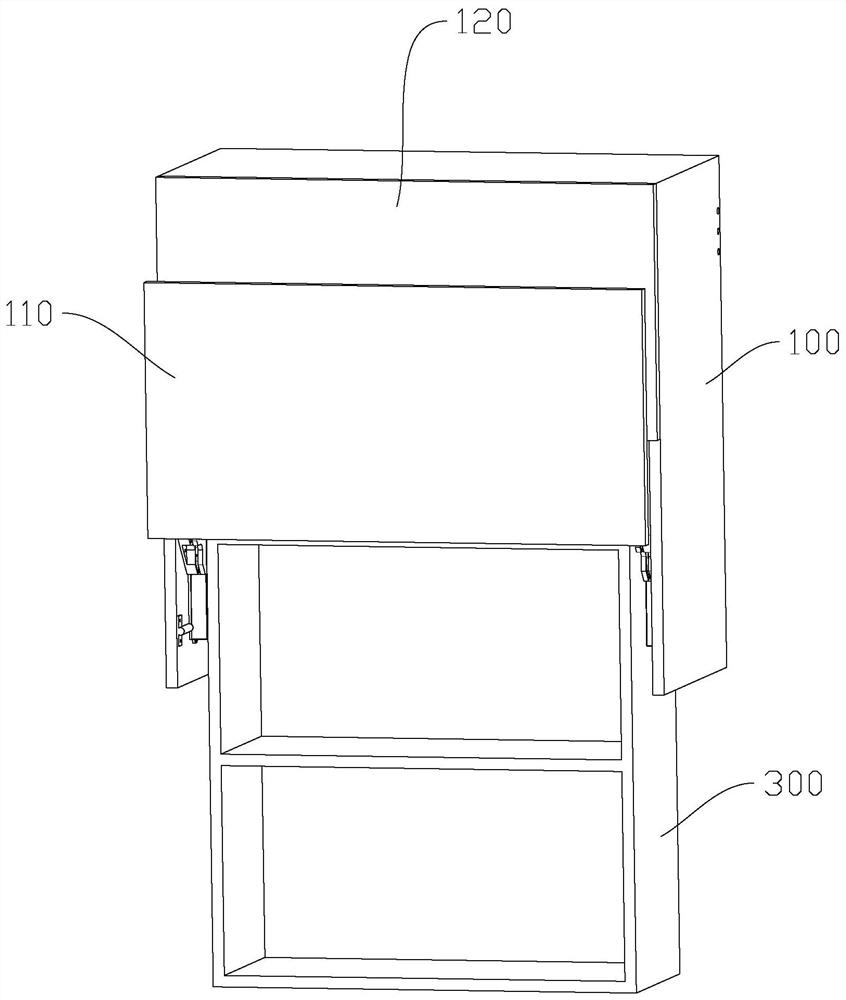

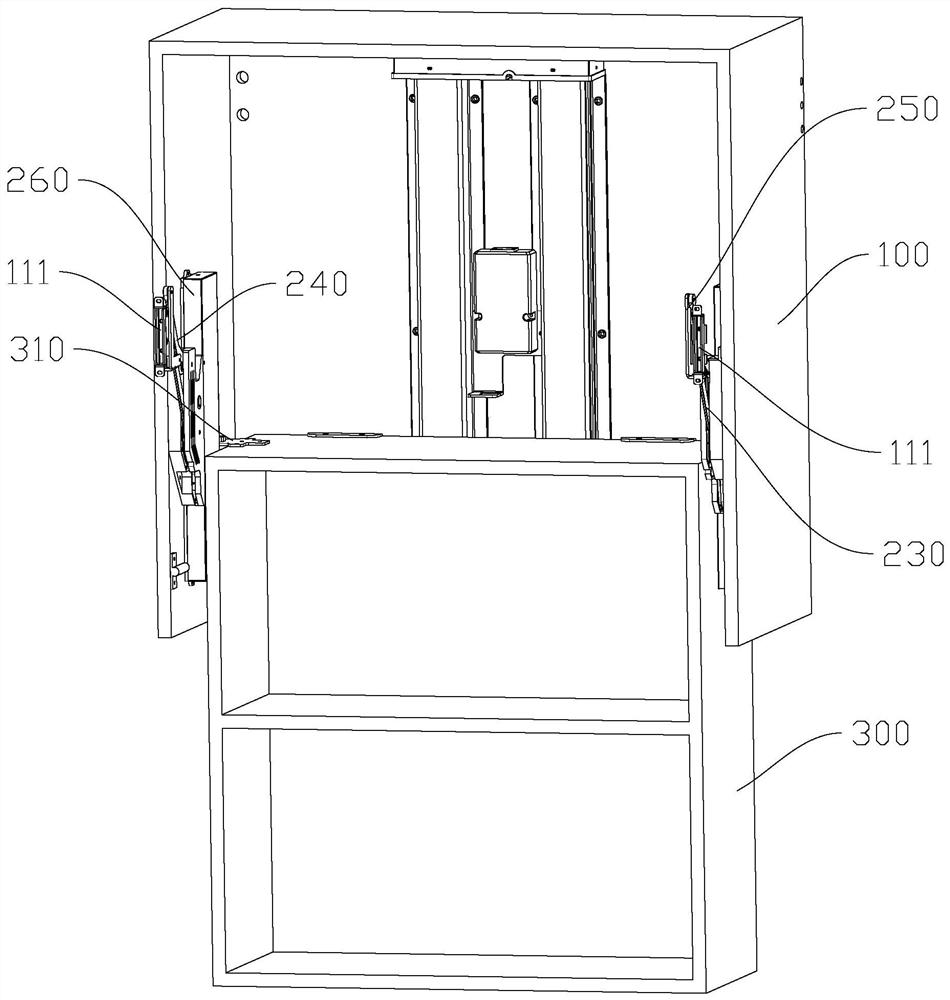

[0041] refer to Figure 1 to Figure 7 As shown, the hanging cabinet in this embodiment includes an outer cabinet 100, the front side of the outer cabinet 100 is provided with an opening and a flip door 110 corresponding to the opening, and a flip door is respectively provided on the inner walls of the two side walls of the outer cabinet Mechanism 200, two flap mechanisms 200 are symmetrically arranged, the flap mechanism can drive the flap 110 to open and close the opening, and the flap mechanism 200 includes a rack 210, a gear 220 meshing with the rack 210, and an active mechanism that rotates synchronously with the gear 220. The rod 230, the driven rod 240 hinged on the inner wall of the side wall of the outer cabinet, and the connecting rod 250 connecting the driving rod 230 and the driven rod 240, the driving rod 230, the driven rod 240 and the connecting rod 250 constitute a parallelogram mechanism, and the connecting rod 250 It is fixedly connected with the flip door 110...

Embodiment 2

[0054] Compared with the first embodiment, the difference of this embodiment is that the hanging cabinet also includes an electric lifting mechanism for driving the inner cabinet 300 to rise and fall. The electric lifting mechanism includes a motor and a screw drive assembly, and the motor is fixed on the outer cabinet. On the inner wall of the back plate, the screw drive assembly includes a vertically arranged drive screw and a drive nut threaded with the drive screw. The drive nut is fixedly connected to the inner cabinet, and the motor drives the drive screw to rotate to make the drive nut move up and down. The drive nut moves up and down to drive the inner cabinet to rise and fall, thereby realizing automatic control of the lifting and lowering of the inner cabinet 300 and improving the user experience.

[0055] It can be understood that, in other embodiments of the present invention, the electric lifting mechanism can also use the lifting adjustment assembly in CN202011197...

Embodiment 3

[0058] Compared with Embodiments 1 and 2, the difference of this embodiment is that the hanging cabinet in this embodiment only includes an outer cabinet, the bottom of the outer cabinet is closed and used for storing articles, and the front side of the outer cabinet is provided with an opening and an outer cabinet. For the flip door corresponding to the opening, an electric push rod for driving the rack 210 to slide up and down is fixed on the inner wall of the side wall of the outer cabinet. This design can save the lifting of the inner cabinet and the lifting mechanism that drives the lifting of the inner cabinet, and can directly realize the opening and closing action of the parallel flip door on the outer cabinet.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap