Electric lifting type hanging cabinet

A lifting and hanging cabinet technology, applied in the field of hanging cabinets, can solve the problems that the maximum height cannot meet the needs of users, and the descending stroke of the inner cabinet cannot be further reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

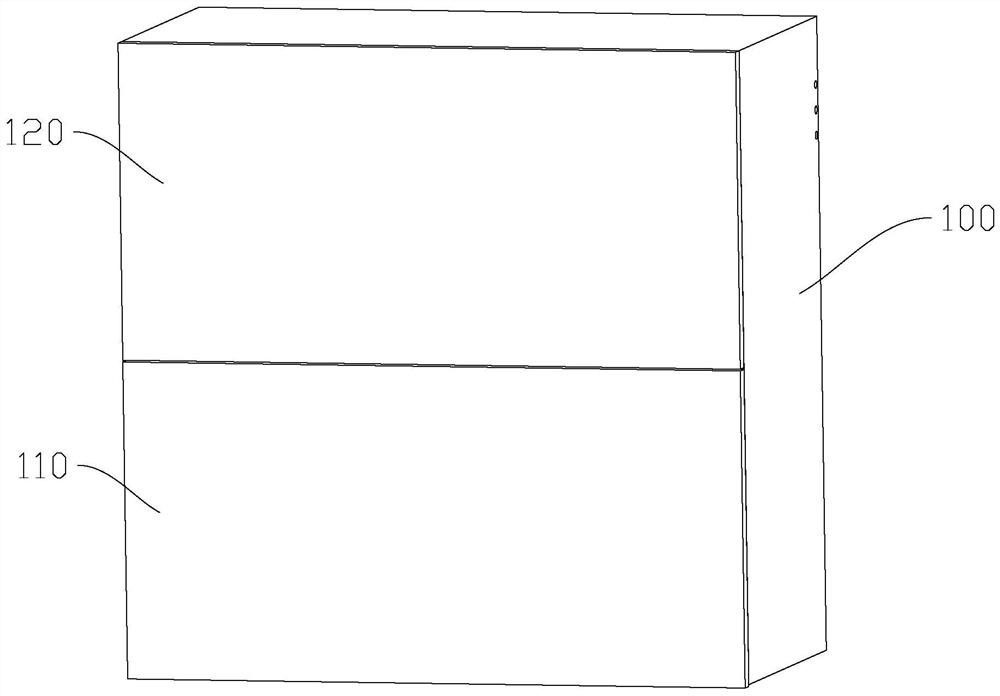

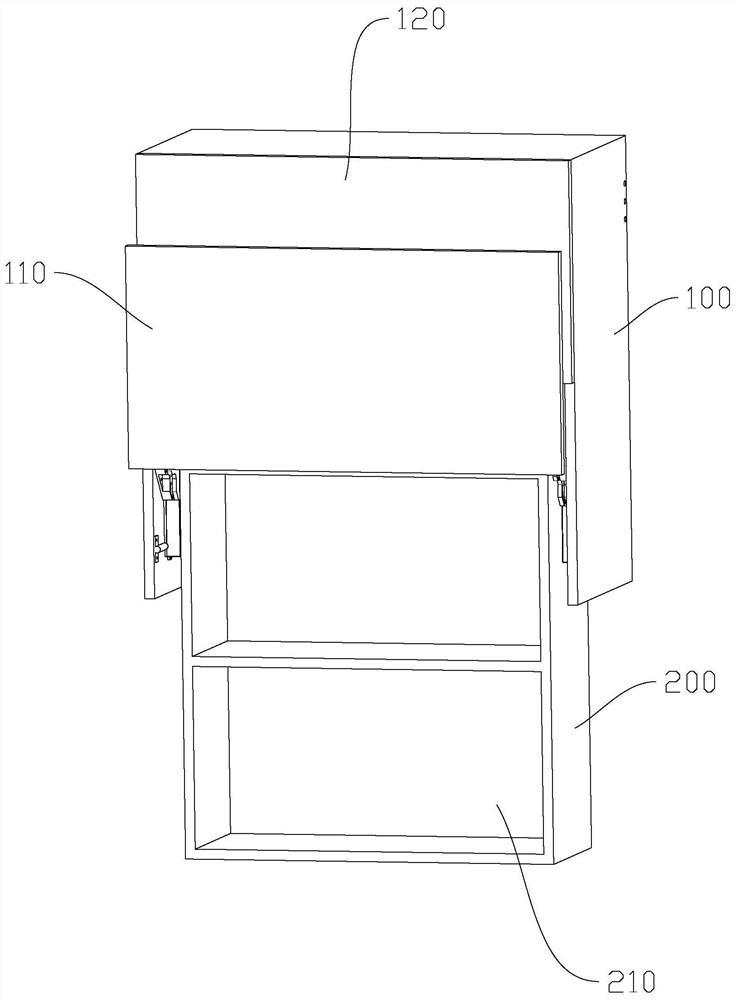

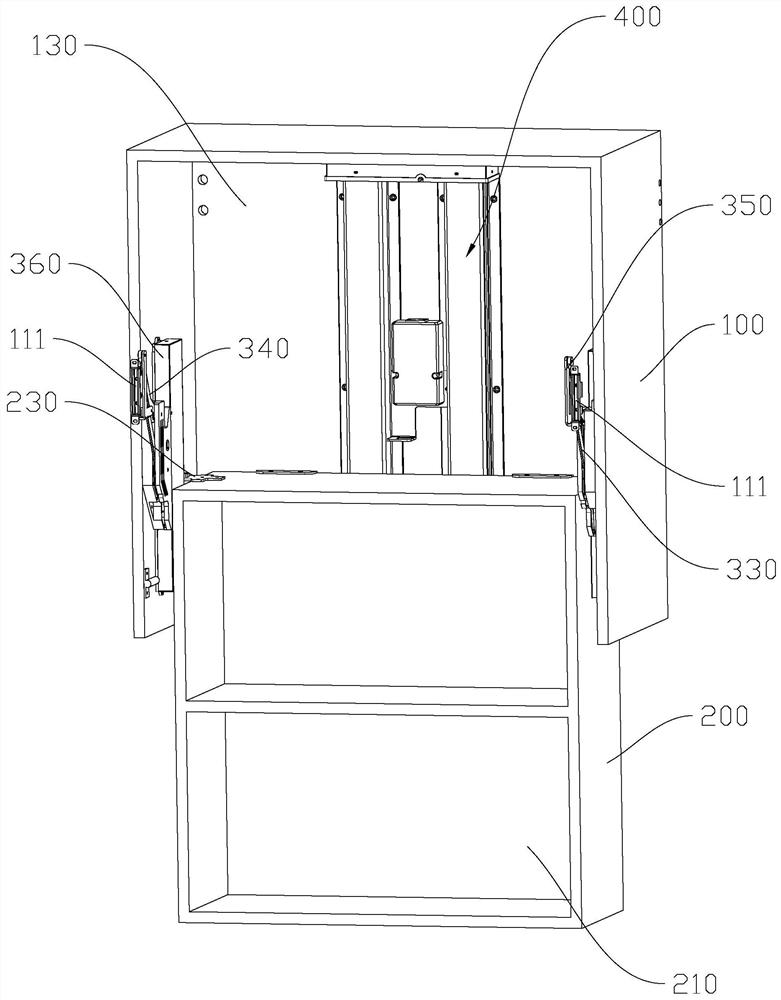

[0051] refer to Figure 1 to Figure 11 As shown, the electric liftable wall cabinet in this embodiment includes an outer cabinet 100 and an inner cabinet 200. The bottom of the outer cabinet 100 is opened to form an entrance and exit for the inner cabinet 200 to enter and exit. In the lifting mechanism 400 that drives the inner cabinet 200 to rise and fall, the lifting mechanism 400 drives the inner cabinet 200 to descend and expose downward through the entrance and exit, so as to be exposed to the outside of the outer cabinet 100; or the lifting mechanism 400 drives the inner cabinet 200 to rise and enter the outer cabinet through the entrance and exit. Inside the cabinet 100 to be stored inside the outer cabinet 100, the lifting mechanism 400 includes a motor 410, two gear boxes 420, and two lifting columns 430 arranged in parallel. The motor 410 includes an output shaft, and the two ends of the output shaft pass through the two gear boxes respectively. 420 is connected with...

Embodiment 2

[0078] Compared with Embodiment 1, the lifting column in this embodiment is a three-section lifting column, including a screw drive assembly and a three-section telescopic sleeve, wherein the screw drive assembly includes an inner screw rod, and a hollow socket outside the inner screw rod. Screw, inner drive nut and outer drive nut, the inner screw rod and the hollow screw rod rotate synchronously and cooperate with the hollow screw rod in axial expansion and contraction, the inner screw rod and the inner drive nut are screwed together, and the hollow screw rod is rotatable with the inner drive nut in the axial direction Upper positioning, the outer wall of the hollow screw is provided with an external thread that matches the outer drive nut, and the three-section telescopic sleeve includes an inner tube, an outer tube, and a middle tube that are sequentially set, the inner tube is set on the outer side of the hollow screw, the inner tube and the outer cabinet The top wall of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap