Locating and gripping experimental device for aircraft thin-wall parts

An experimental device and technology of thin-walled parts, applied in the field of aircraft thin-walled parts positioning and clamping experimental device, to achieve the effects of strong adaptability, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

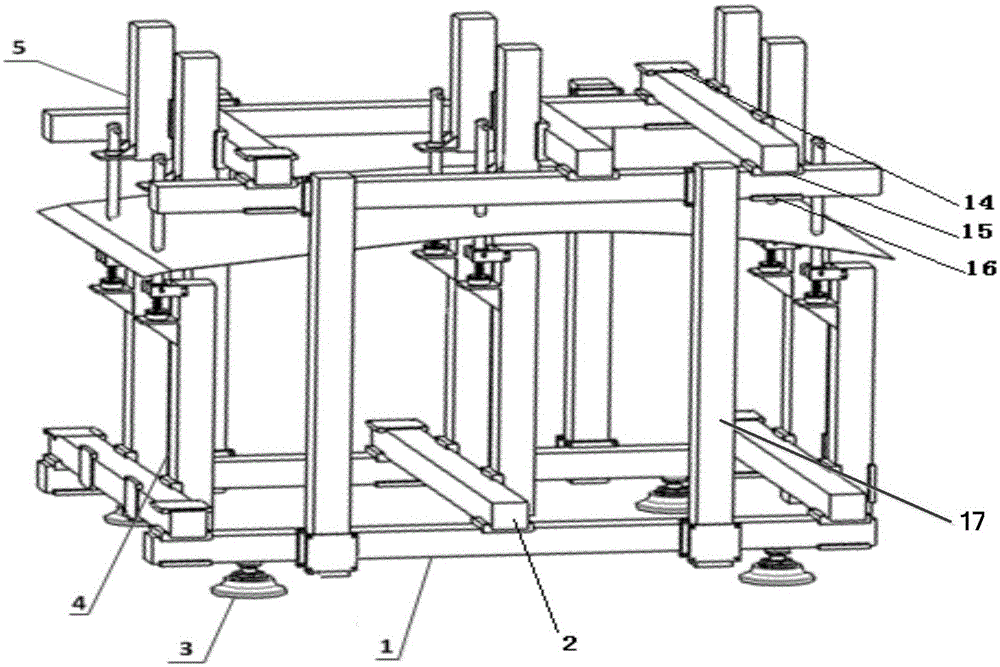

[0019] This embodiment is an experimental device for positioning and clamping aircraft thin-walled parts.

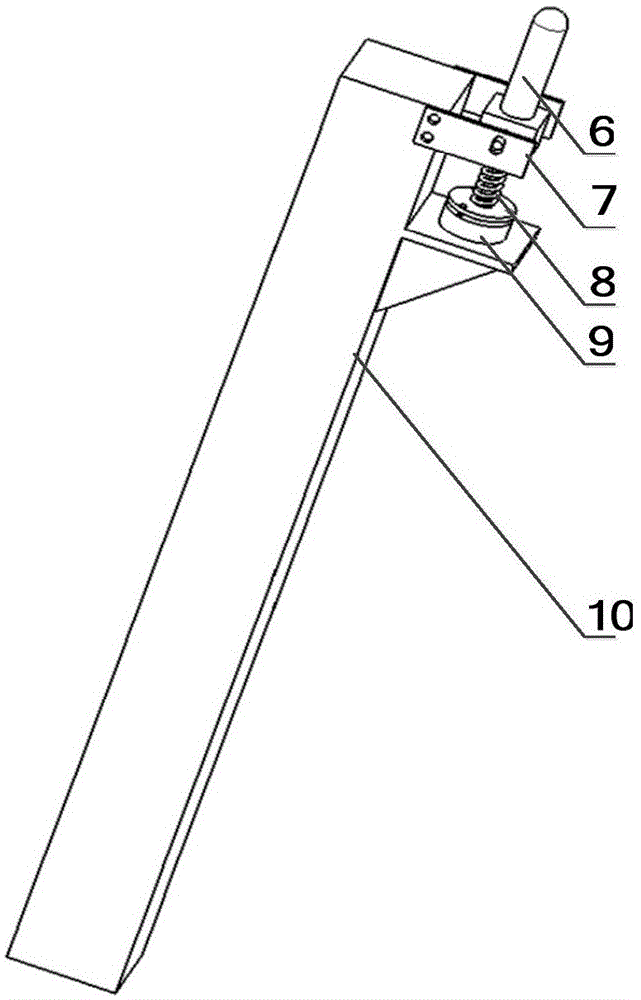

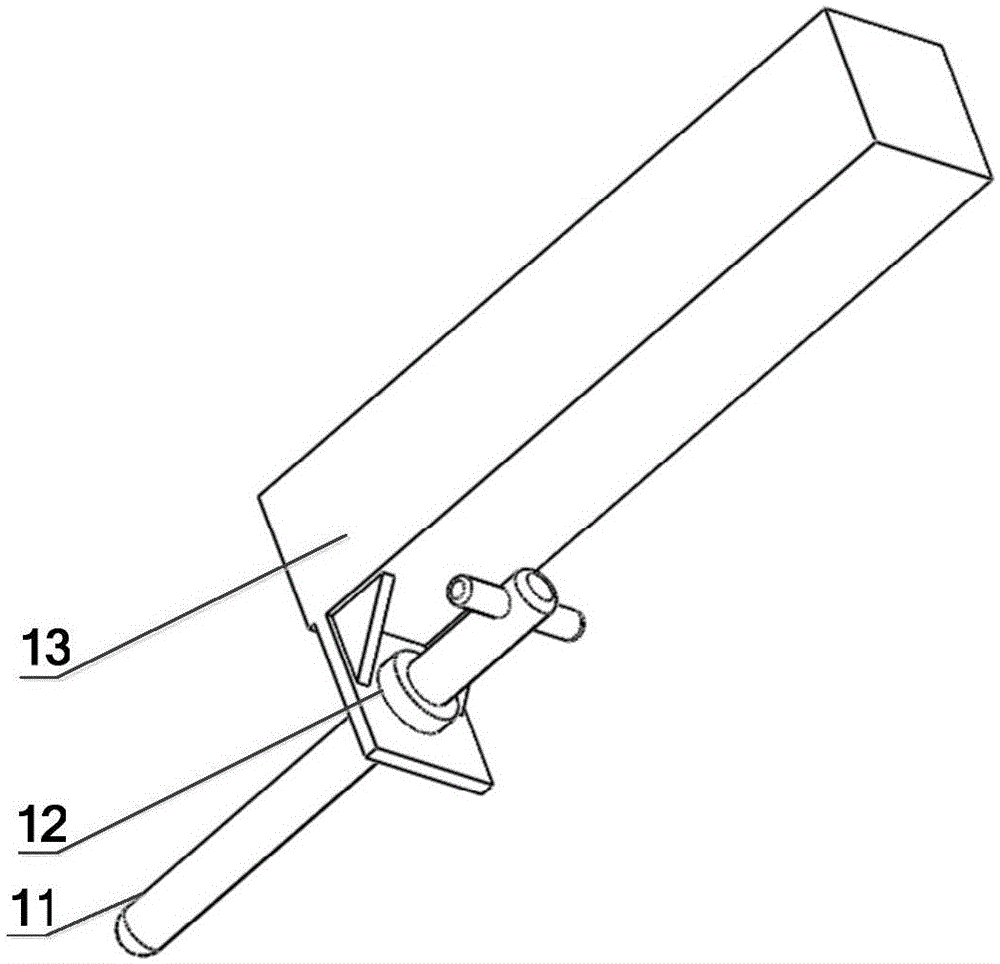

[0020] refer to Figure 1 to Figure 5 , The experimental device of this embodiment is composed of a plurality of positioners 4, a plurality of holders 5, a leveling support 3 and a support frame. The support frame structure is composed of crossbeam 1, vertical support beam 17, connecting beam 2 and connecting plate. The connecting plate includes an upper connecting plate 14, a middle connecting plate 15 and a lower connecting plate 16. The upper connecting plate 14 and the lower connecting plate 16 have the same structure; The four vertical beams 17 are fixedly connected to the four beams 1 respectively, and the multiple connecting beams 2 are fixedly installed on the upper surface of the upper beam 1 and the upper surface of the lower beam 1 of the support frame in parallel, and the connecting beams 2 on the upper surface of the upper beam 1 are connected to the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com