Automatic chiseling equipment for concrete member and construction method

A technology of concrete and concrete test blocks, which is applied to stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of wasting time and insufficient chiseling effect, and achieve the effect of ensuring construction safety, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

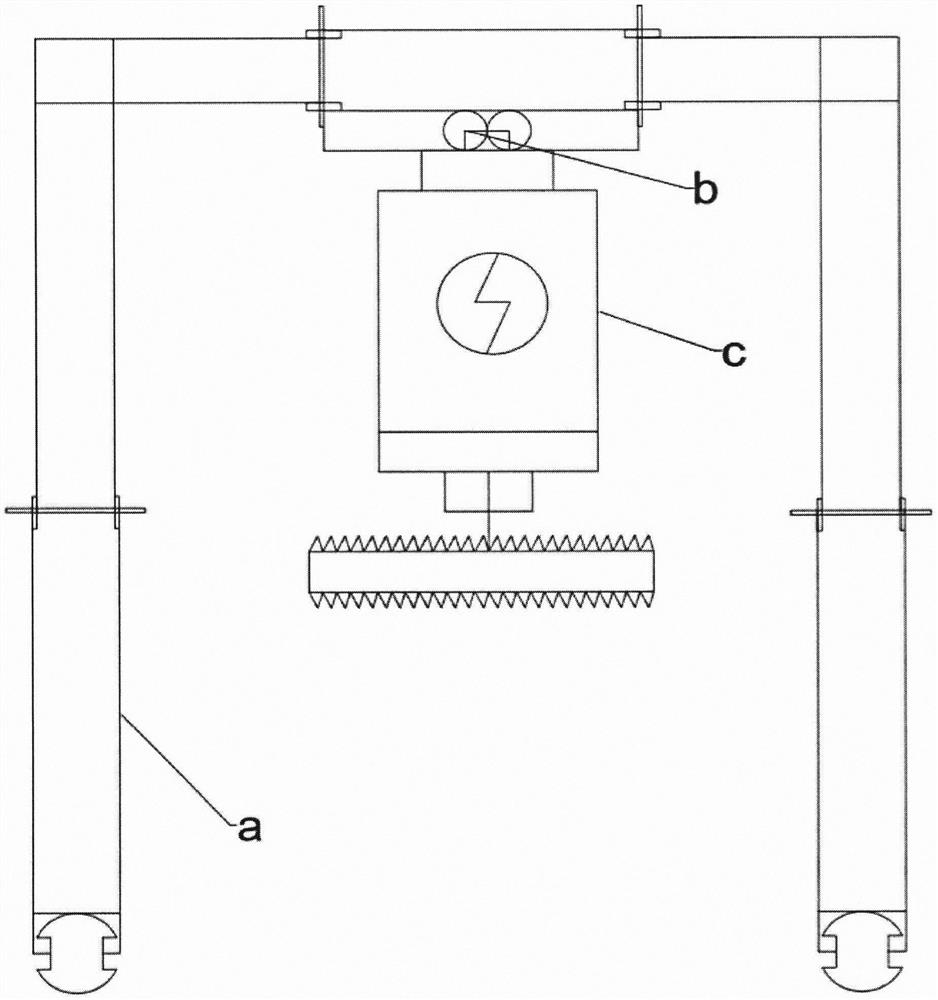

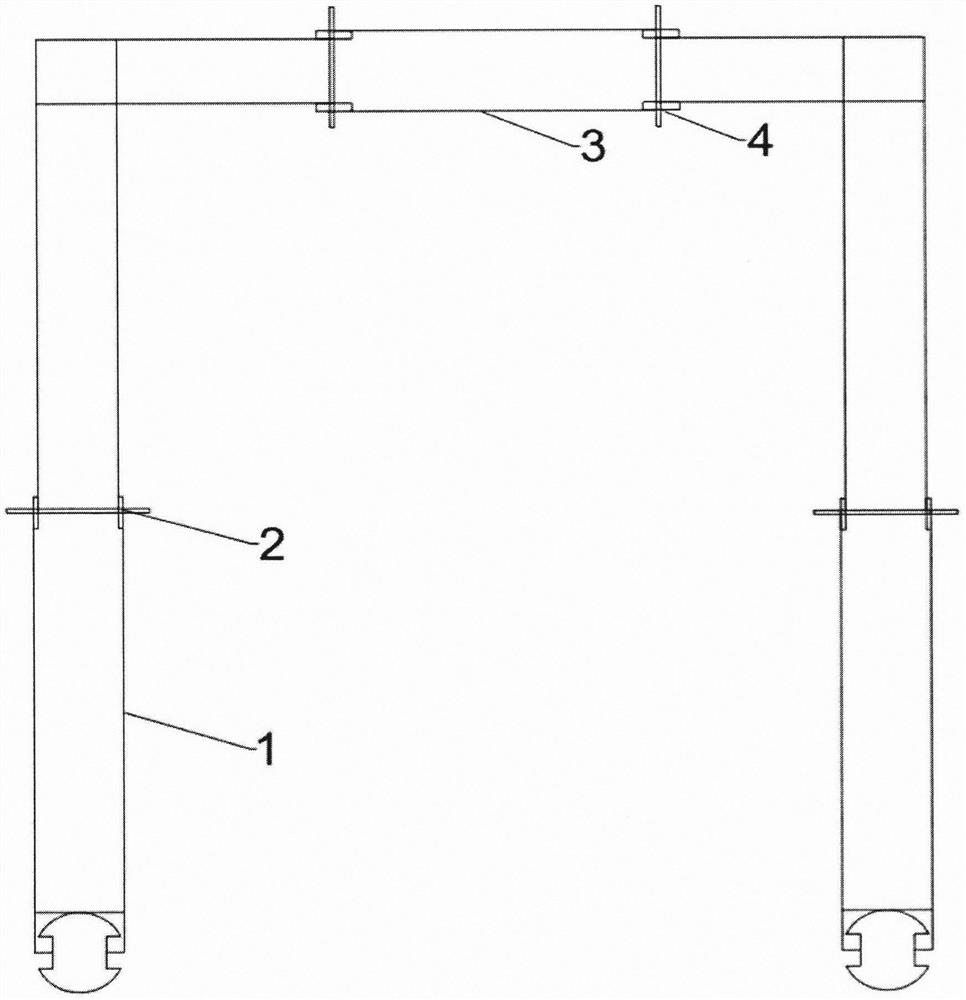

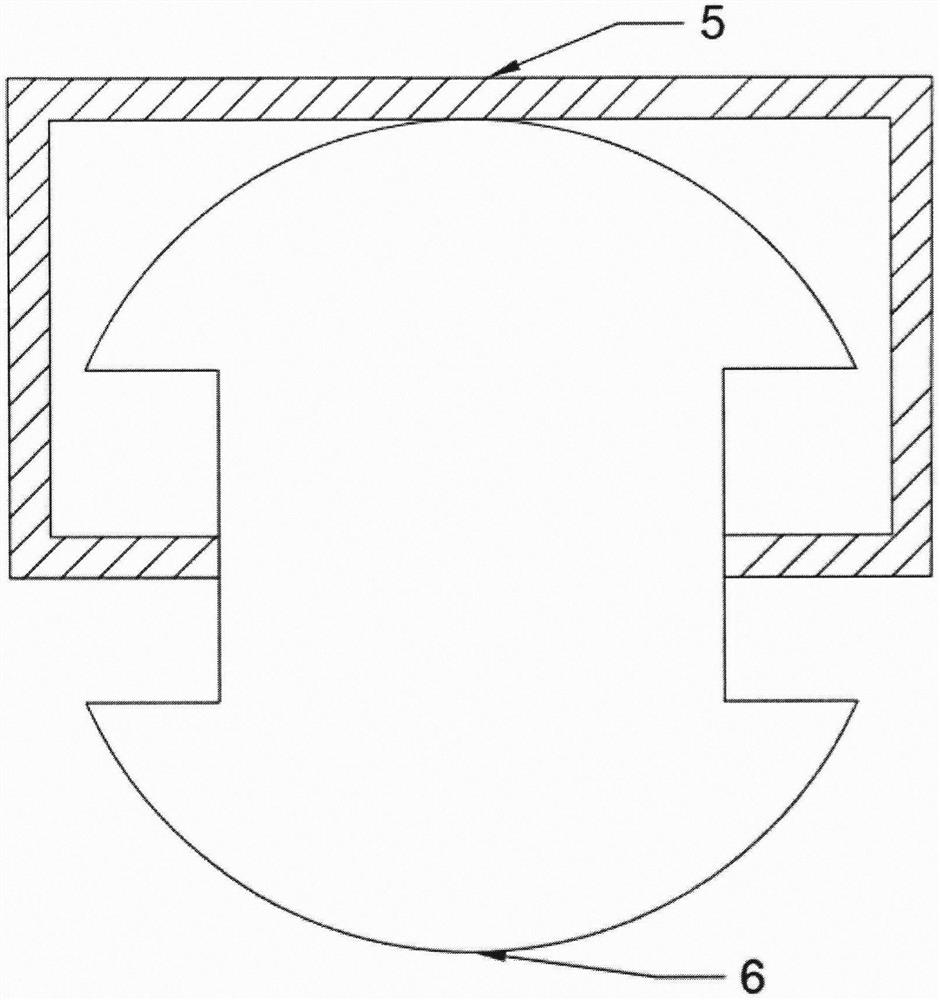

[0033] In order to have a deeper understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Please refer to the attached figure 1 ~ attached Figure 5 ,

[0034] In the example of the present invention, an automatic chiseling equipment for concrete components, the equipment includes a longitudinal steel support 1, a lifting device 2, a transverse steel support 3, a telescopic device 4, a brake device 5, special-shaped wheels 6, track beams 7, and motor travel Device 8, chisel hair tube 9, and motor 10 are jointly formed.

[0035] In the present invention, the support system a is composed of vertical steel support 1, horizontal steel support 3, lifting 2 and telescopic 4 devices distributed on both sides, so as to ensure the stability of the equipment and the safety of construction.

[0036] In the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com