Split installation method of high connecting beam type precast concrete wall, high connecting beam split node and high connecting beam, high connecting beam type precast concrete wall

A technology of prefabricated concrete and installation method, applied in the direction of walls, joists, girders, etc., can solve the problems of disconnection of shear steel bars, inability to disassemble, unable to play a role in shear resistance, etc., to ensure stability and improve structural safety. , the effect of solving structural safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

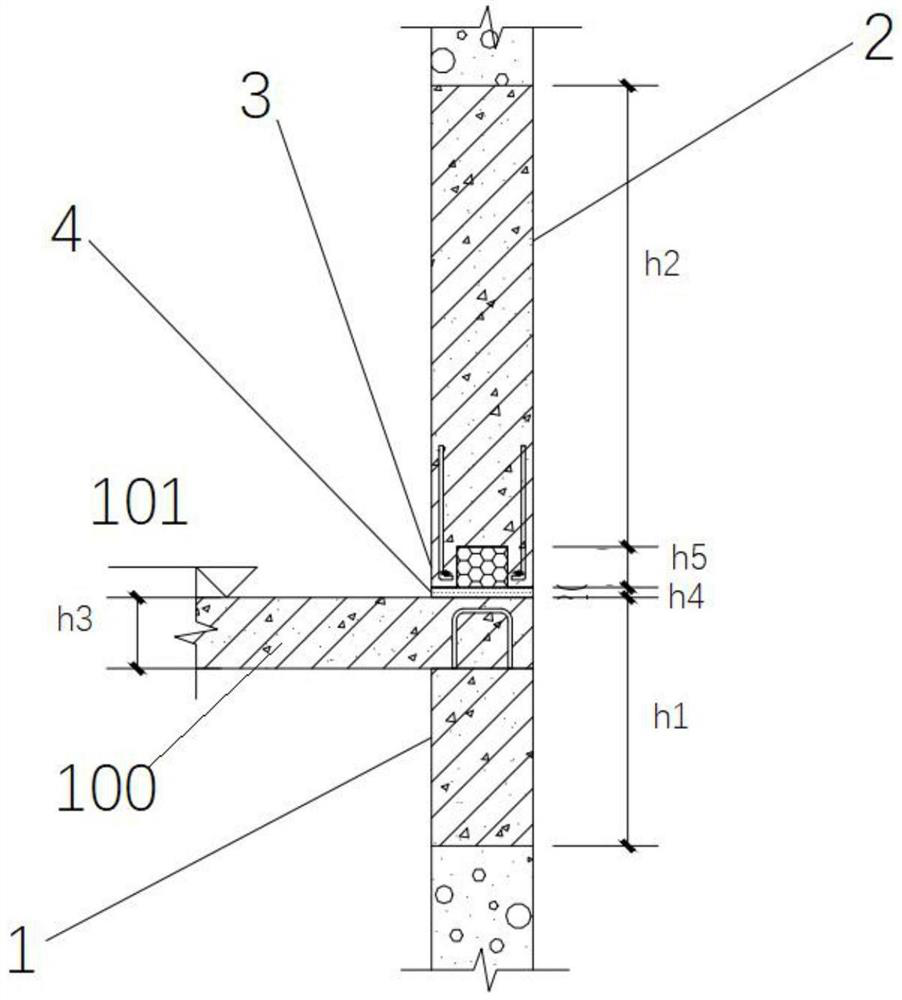

[0030] like figure 1 and figure 2 As shown in the figure, the splitting and installation method of the high connecting beam type precast concrete wall includes the following steps:

[0031] Splitting the high connecting beam into independent upper connecting beam 2 and lower connecting beam 1 along the floor elevation 101;

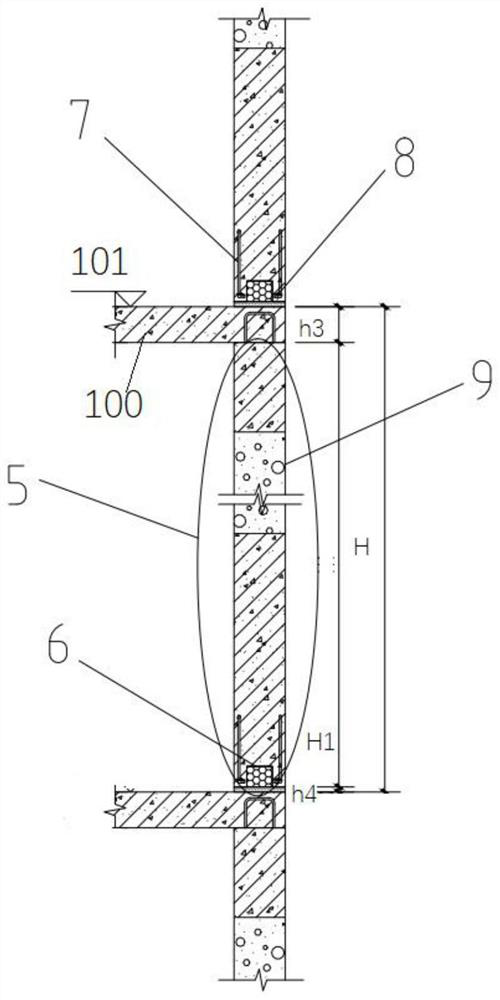

[0032] Splitting the prefabricated concrete wall into one-piece concrete wall bodies 5 along each of the floor elevations 101 in the height direction;

[0033] Lay the seat slurry layer 4 below the upper connecting beam 2 above the floor elevation 101;

[0034] A filling layer 6 is arranged at the inner bottom of the concrete wall 5 along the length direction of the precast concrete wall, so that the filling layer 6 is located above the slurry layer 4;

[0035] Make supports 3 on both sides of the filling layer 6;

[0036] The concrete wall 5 is hoisted and fixed to the floor slab 100, and is poured integrally with the floor slab 100 on the same floor...

Embodiment 2

[0038] like figure 1 and figure 2 As shown, in the method for disassembling and installing a high-coupling beam-type precast concrete wall described in Embodiment 1, it is also possible to specifically split the high-coupling beams into independent upper coupling beams 2 and lower coupling beams 1 along the floor elevation 101. , first measure the height h1 of the high connecting beam below the floor elevation 101; set the height of the lower connecting beam 1 as h1.

[0039] It is also possible to specifically measure the height h2 of the high connecting beam beyond the floor elevation 101 before splitting the high connecting beam into the independent upper connecting beam 2 and the lower connecting beam 1 along the floor elevation 101; The height of 2 is set to h2.

[0040] Specifically, before splitting the high coupling beam into independent upper coupling beam 2 and lower coupling beam 1 along the floor elevation 101 , first measure the total height h of the high coupl...

Embodiment 3

[0043] like figure 1 and figure 2 As shown, the high coupling beam split node is used to realize the split installation method of the high coupling beam type precast concrete wall described in any one of Embodiment 1 or Embodiment 2, and the high coupling beam split node includes a slurry layer 4 and a filling layer 6, the seat The slurry layer 4 is laid above the floor elevation 101 and below the upper connecting beam 2; the filling layer 6 is arranged in the concrete wall 5 along the length direction of the precast concrete wall, and the filling layer 6 is located above the seat slurry layer 4; Supports 3 are provided on both sides of the filling layer 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com