A multi-flow hole type safety shut-off plate valve

A technology of multi-flow holes and flat valves, which is applied in wellbore/well valve devices, wellbore/well components, sealing/isolation, etc., and can solve the problems that flat valves cannot achieve multi-flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

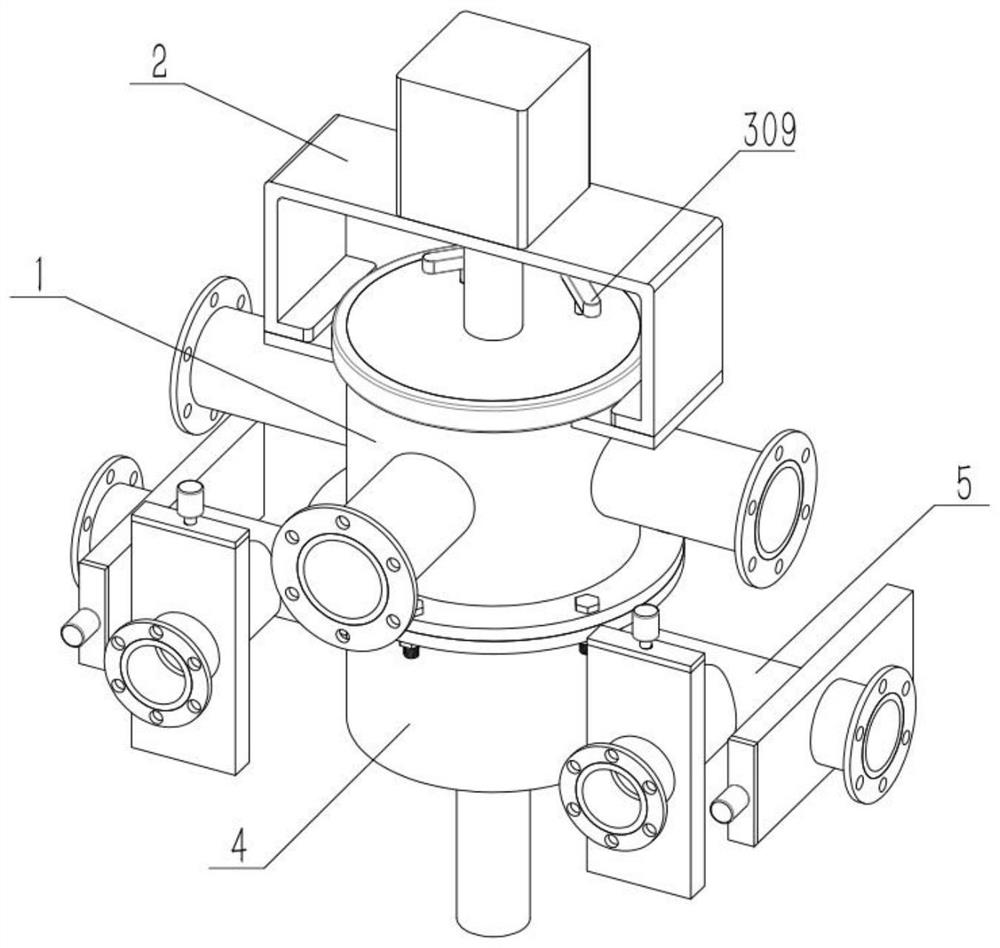

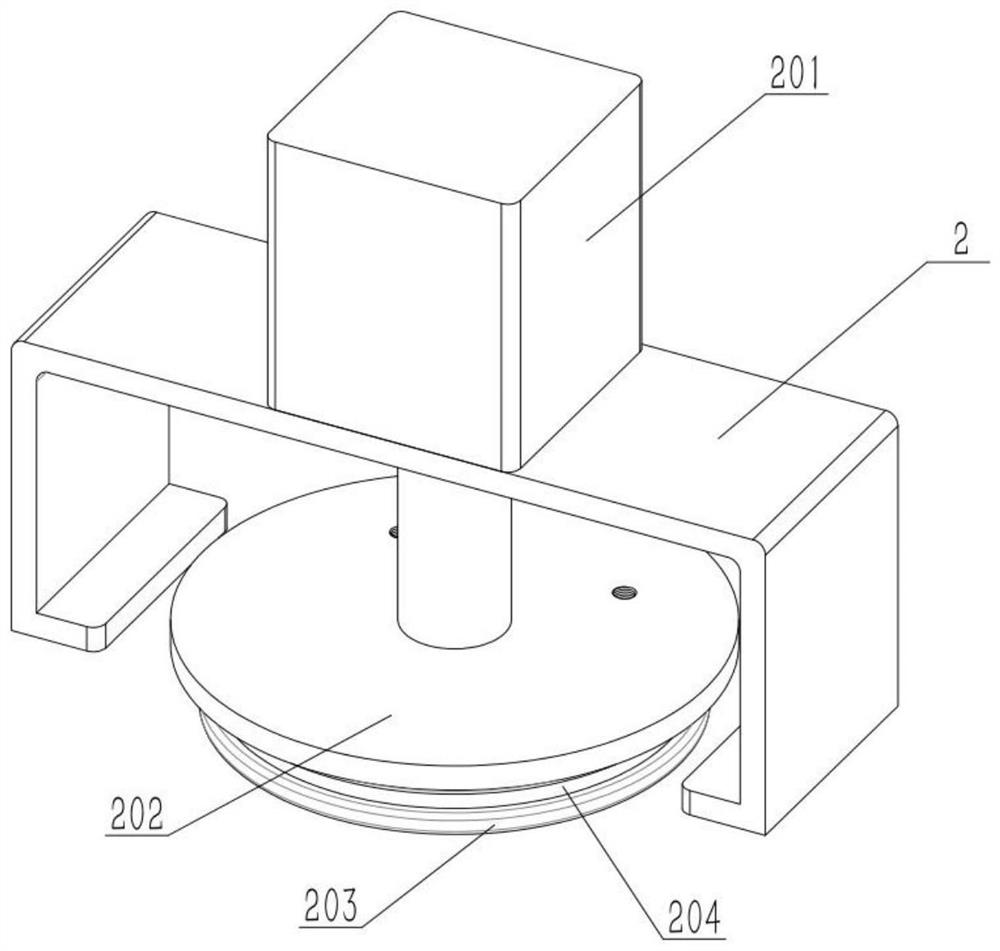

[0029] As shown, a multi-flow well safety truncated flat valve, including a multi-flow well-type safety truncated flat valve, including housing I1, mounting ring 101, buckle 202, plug column 203, central column 3, medium The through hole 301, the die 302, the medium slot 303, the bypass hole 304, the plate I305, the connecting port I306, the connecting block 307, the screw I308, and the housing II4, the upper end of the housing I1 Secondary mounting ring 101, mount The ring 101 rotates the stopper 202, the lower end fixation plunger 303 of the fastener 202, and the plunger 203 rotate within the housing I1, the center post 3 is fixed to the center of the lower end of the fasteper 202, and the inverse hole 301 is The middle portion of the central column 3 is disposed, and the central column 3 is uniformly connected with four diaphragulars 302, and each of the upper ends of the two diaphragulars 302 are provided in each of the two grooves 303, located in front of the front. The 302 i...

specific Embodiment approach 2

[0030] As shown, the multi-flow well safety truncated flat valve also includes a plug groove 204, and a plug groove 204 is provided in the middle of the plug column 203. Increase the sealing effect after the deformation.

specific Embodiment approach 3

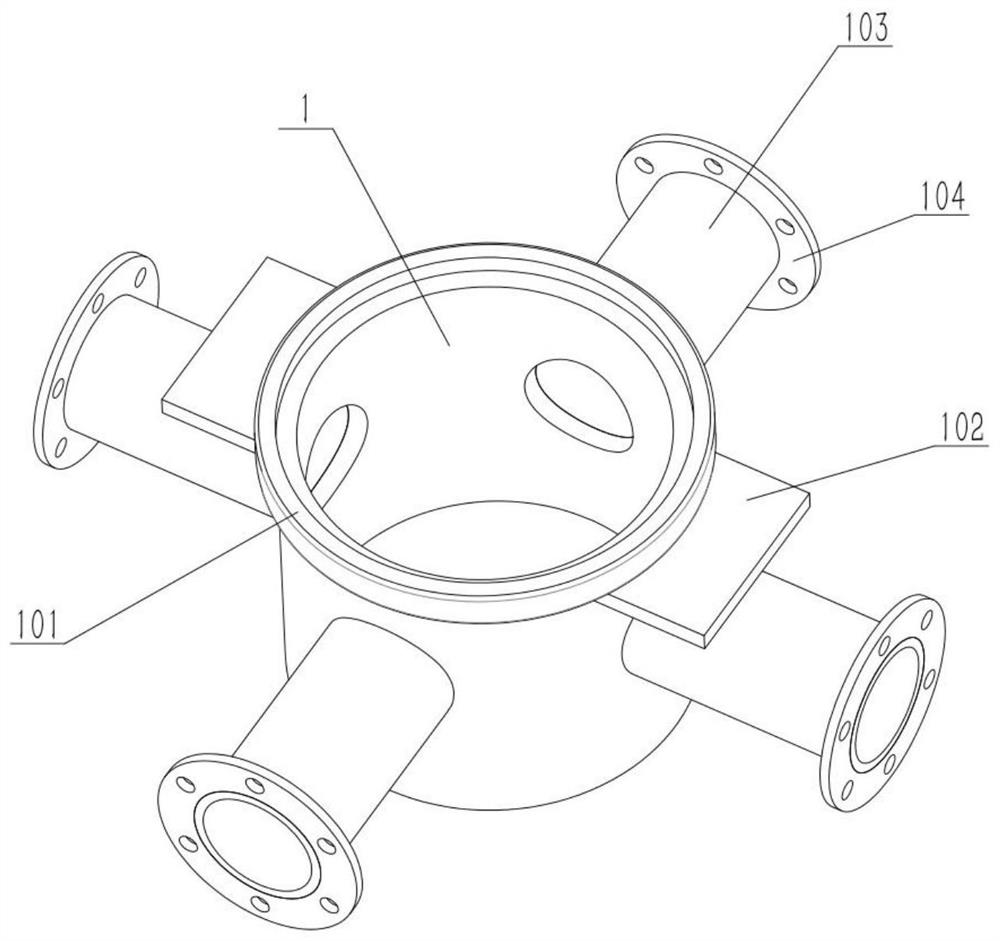

[0031] As shown, the multi-flow well safety truncated flat valve also includes a connecting tube I103, and the housing I1 is uniformly secured and connected to four connecting tubes I103.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com