A module exchange device for cubing gage

A checking tool and slider technology, which is applied to measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of large space occupation, troublesome replacement, and high cost, saving production and processing costs, avoiding bumps, and being easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions protected by the present invention will be specifically described below in conjunction with the accompanying drawings.

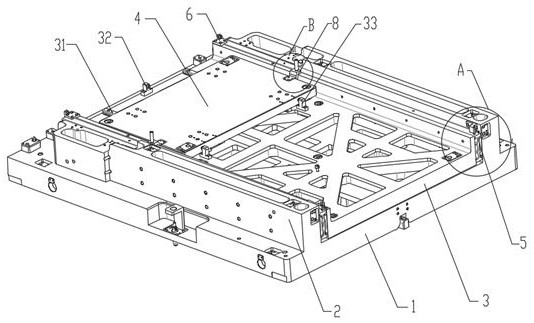

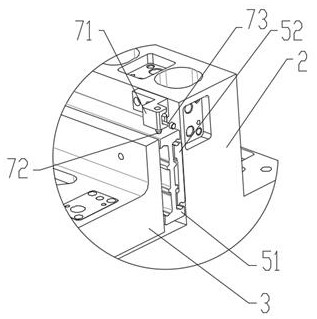

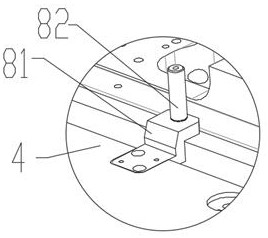

[0026] Such as figure 1 , a modular exchange device for Cubing inspection tools, including: a base plate 1, side baffles 2 arranged in parallel on both sides of the base plate 1, a sliding frame 3 arranged between the side baffles 2, the sliding frame 3 It is connected with the bottom plate 1 and the side baffles 2 through a guide rail assembly 5. The guide rail assembly 5 includes: a slide rail 51 and a guide rail 52. The slide block 51 is fixed on both sides of the sliding frame 3, and the guide rail 52 is set Corresponding to the side baffle 2, the slider 51 can move laterally along the guide rail 52, and a connecting plate 4 is arranged at one end of the sliding frame 3, and the connecting plate 4 and the sliding frame 3 are connected by a linear slide. The rails 31 are connected so that the connecting plate 4 can slide on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com