Actuator

A technology for adjusting drives and adjusting heads, applied in the direction of control/adjustment systems, instruments, valve details, etc., which can solve problems such as low maintenance, cracking, and damage to the housing wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

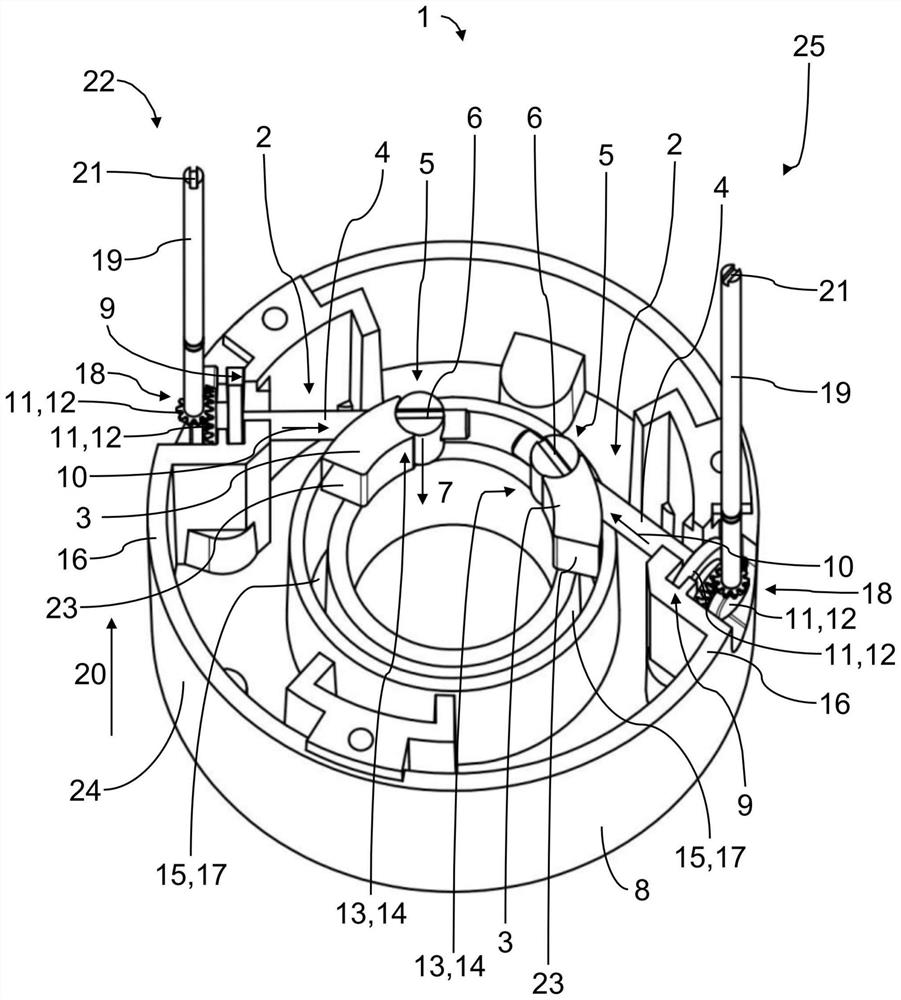

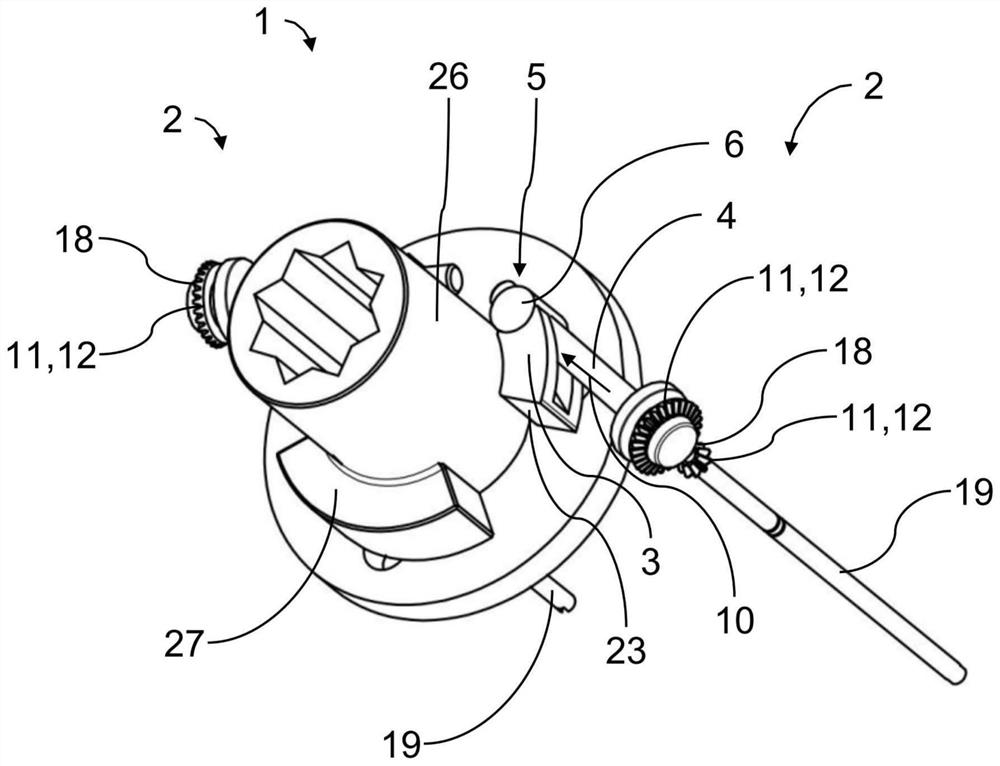

[0029]figure 1 and figure 2 An actuating drive is shown in each case, generally designated 1 , which can be used, for example, for a valve body of an actuating valve.

[0030] exist figure 1 and figure 2 The embodiment variant of the adjusting drive 1 shown in has two stop devices 2 which can each be used to adjust the position of an end stop of a component of the drive train for the adjusting drive 1 . The part can be, for example, an eccentric element 27 which is connected to the drive shaft 26 (see figure 2 ).

[0031] In this case, the end stops are respectively adjusted by the end stop elements 3 in that the position of the two end stop elements 3 is variable.

[0032] Each end stop element 3 is in each case operatively connected to the first adjusting element 4 , so that when the corresponding adjusting element 4 is actuated and / or when the adjusting element 4 is moved, the position of the associated end stop element 3 takes place. Change.

[0033] A first trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com