Instant soybean protein composition and preparation method thereof

A technology of soybean protein and soybean protein powder, applied in the direction of plant protein processing, etc., can solve the problems of poor solubility and dispersibility of soybean protein isolate, difficulty in instant dissolution, uniform and stable effect, etc., to reduce the risk of cardiovascular and cerebrovascular diseases, The effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0116] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples are not intended to limit the protection scope of the present invention.

[0117] The instant soybean protein powder used as raw material in the examples was purchased from Shandong Wandefu Industrial Group. Milk protein was purchased from Fonterra Trading (Shanghai) Co., Ltd. Rice protein was purchased from Jinnong Biotechnology Co., Ltd. White sugar was purchased from COFCO Tunhe Co., Ltd. Corn flakes, starch, and oatmeal powder were purchased from COFCO Rice. Sunflower oil and linseed oil were purchased from COFCO. Cream powder was purchased from Taylor's Food Ingredients Co., Ltd. Multivitamin powder and multimineral powder were purchased from DSM China Co., Ltd. Compound probiotic powder (including Bifidobacterium bifidum TMC3115, Lactobacillus plantarum LP45, Lactobacillus acido...

preparation example 1

[0135] With 500g protein content being 35wt%, carbohydrate 60wt% flavored soy protein isolate powder (purchased from Wandefu Industrial Group Co., Ltd.) as protein matrix, 0.25g anti-caking agent (silicon dioxide) is fully mixed with the above-mentioned protein matrix Homogenize as a protein matrix powder, and then prepare according to the following steps:

[0136] (1) preparation solution A and solution B: solution A is 225g pure water, and solution B is the aqueous solution that 75g contains 35mg modified soybean lecithin, 5mg glyceryl monostearate, 10mg triglyceryl stearate;

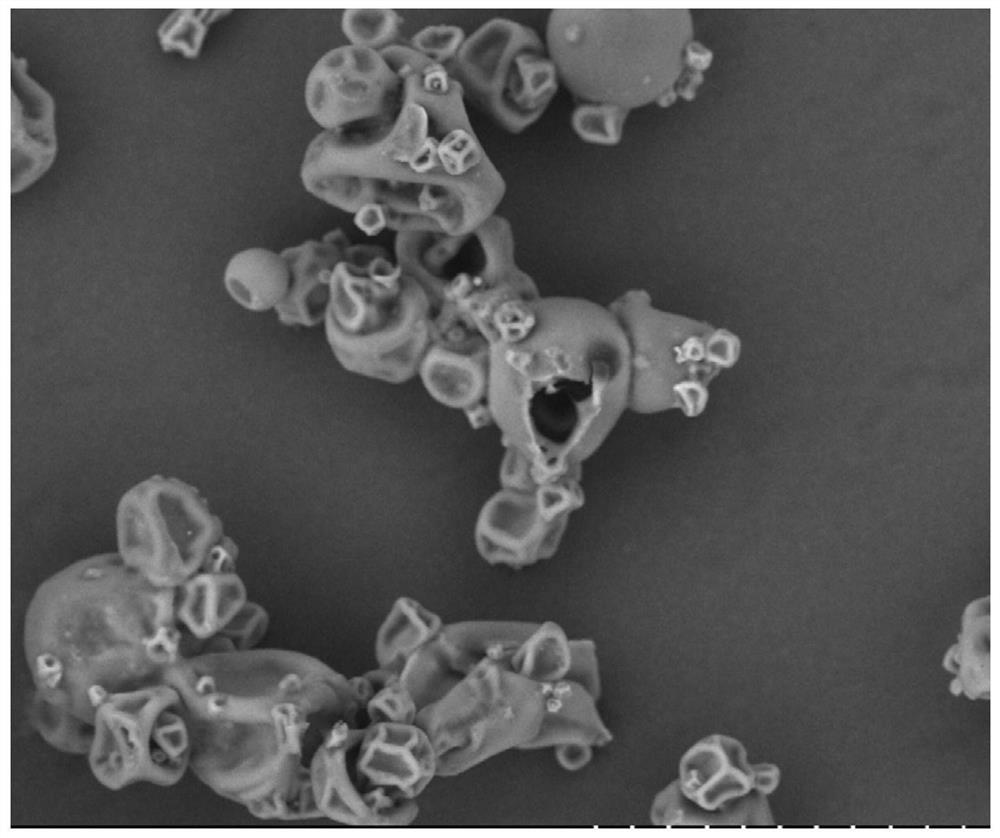

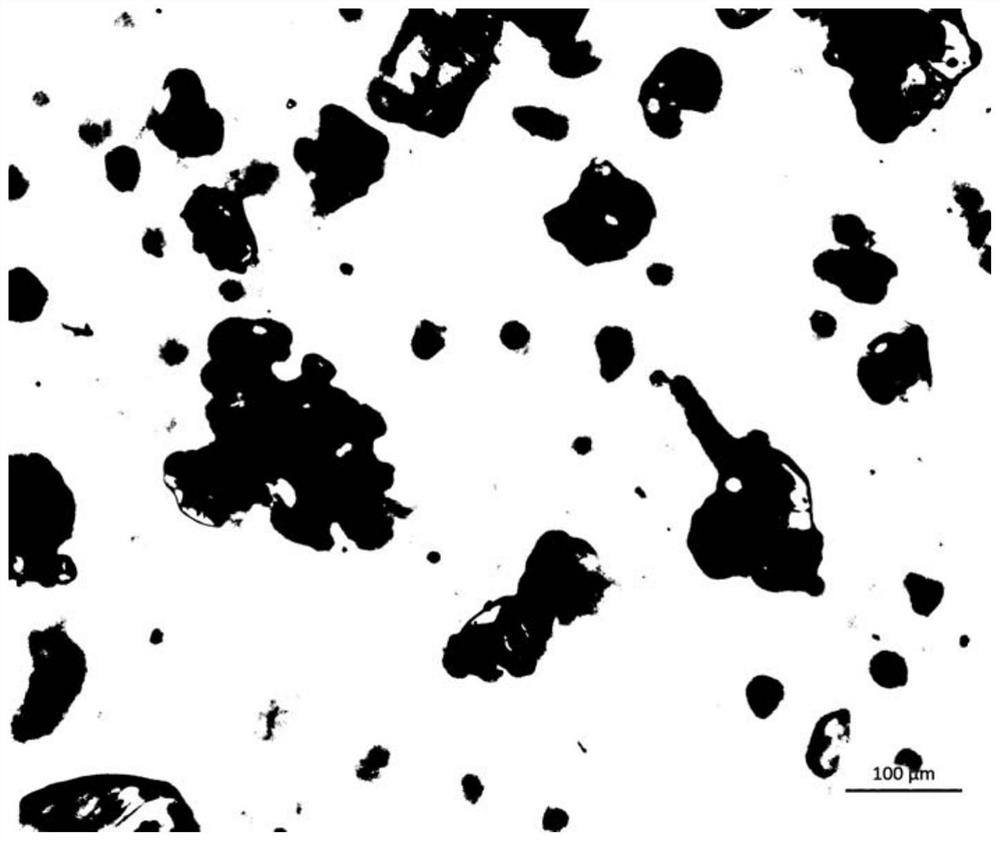

[0137] (2) In DIOSNA Minilab, set the air inlet temperature to 80°C, spray solution A into the fluidized protein matrix powder in the fluidized bed at an injection rate of 20g / min for wet granulation, and form the first mixture Particles; wherein, after raising the temperature of the material from 25°C to 35°C at 10°C / min, start adding solution A and maintain it for 10 minutes, and then increase to 40...

preparation example 2

[0142] With 500g protein content being 35wt%, carbohydrate 60wt% flavored soybean protein isolate powder (purchased from Wandefu Industrial Group Co., Ltd.) as protein matrix, 0.5g anticaking agent (0.45g calcium silicate, 0.05g magnesium carbonate ) and the above-mentioned protein matrix are thoroughly mixed as a powder protein matrix. Then follow the steps below to prepare:

[0143] (1) preparation solution A and solution B: solution A is the aqueous solution that contains 15% protein substrate for 250g, and solution B is the aqueous solution that contains 20% protein substrate for 75g;

[0144] (2) In the DIOSNA Minilab, the temperature of the air inlet is 65°C, and the solution A is sprayed into the fluidized powder protein matrix at a spray rate of 19.5g / min for wet granulation to form the first mixture granules; wherein, Set the temperature of the material at 35°C until the solution A is added;

[0145] (3) Spray solution B into the fluidized first mixture particles at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com