A microwave heating exhaust packaging bag

A packaging bag and heat-sealing layer technology, applied in the field of packaging bags, can solve problems such as low sealing strength, consumer panic, and poor consumer experience, and achieve good high temperature resistance, good consumer experience, and soft sound effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

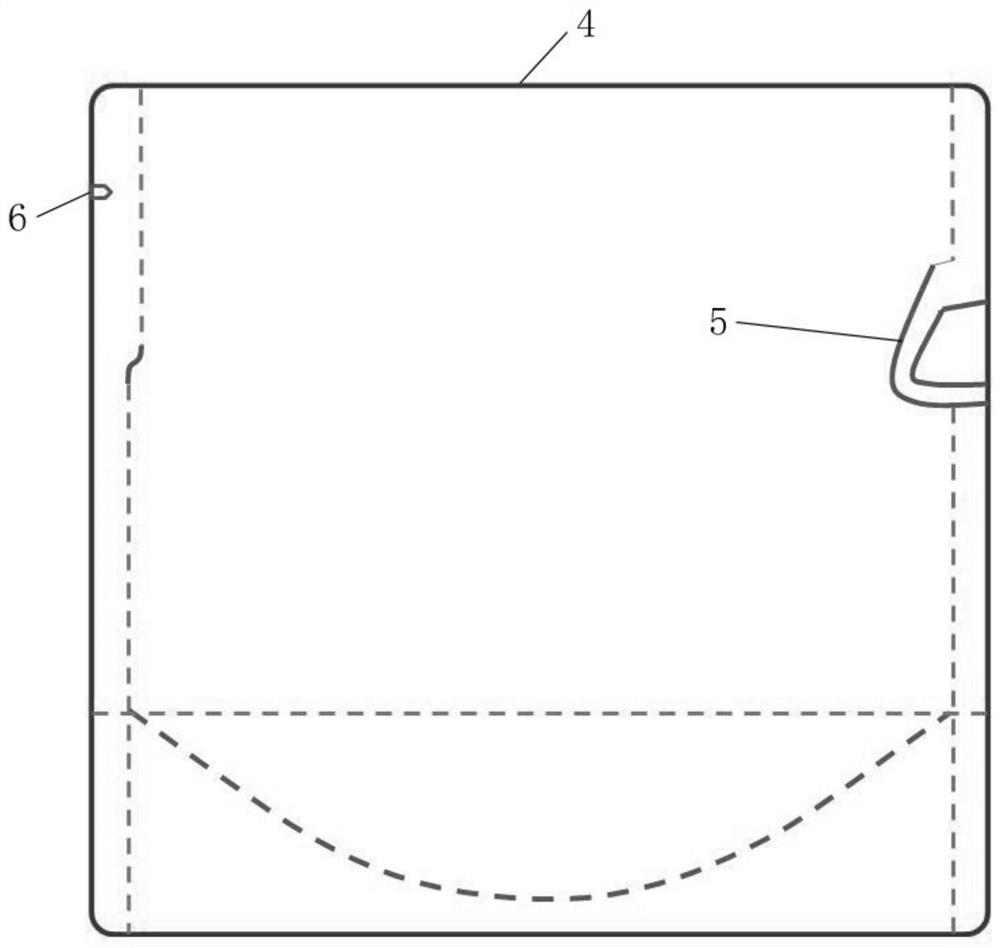

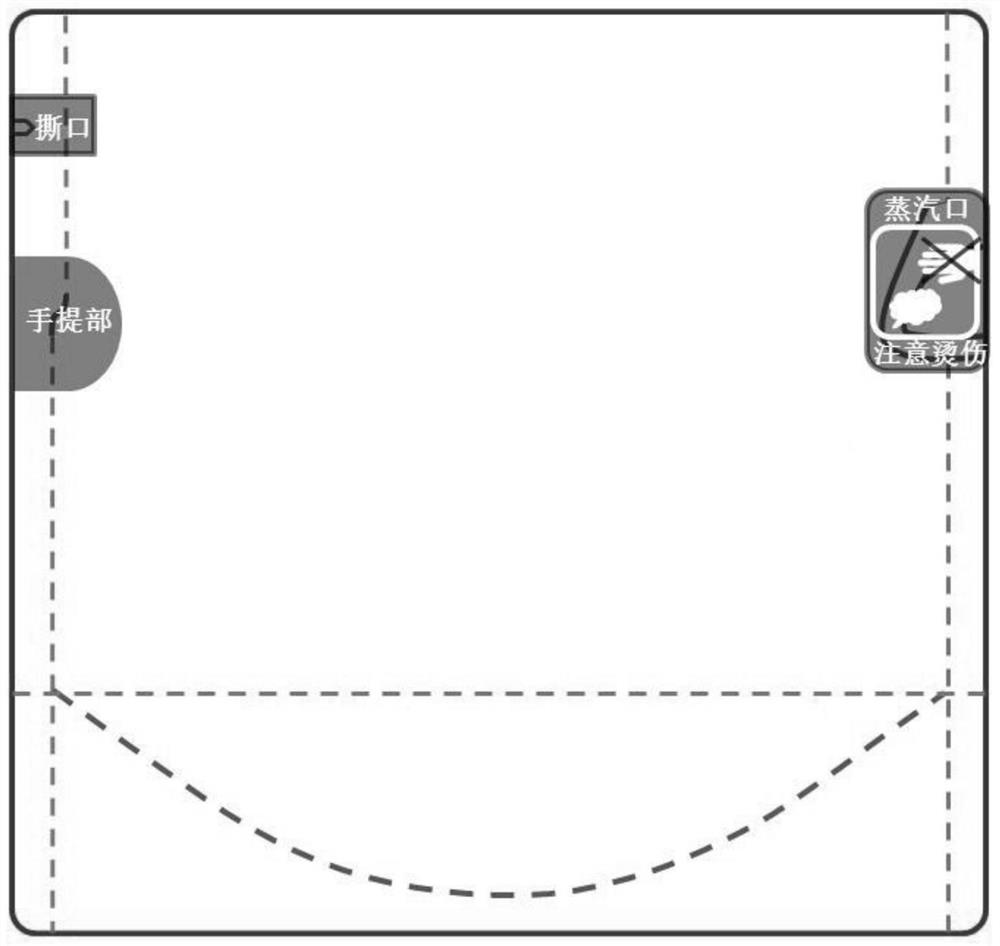

[0042] like Figure 1-3 As shown in the figure, an automatic exhaust stand-up bag for microwave heating, the bag body 4 is made of multi-layer composite film, one side of the bag body 4 has a special-shaped sealing edge, and the special-shaped sealing edge has a protrusion toward the middle of the bag body, The protruding portion constitutes the exhaust port 5, and the sealing strength at the exhaust port is not greater than the sealing strength of the sealing edges on both sides. Preferably, the sealing strength at the exhaust port is 25-60N. The sealing edge on the other side of the bag body 4 is wide at the top and narrow at the bottom, and has a tear opening 6 on the upper part, and the outer layer of the finished self-supporting bag is also printed or adhered with a prompt sticker.

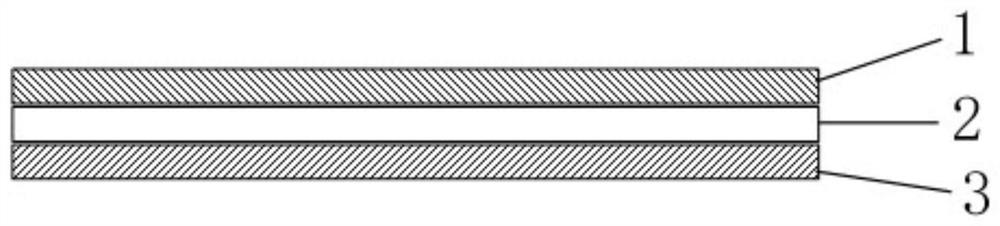

[0043] The structure of the composite film is alumina PET / NY / CPP, and from the outside to the inside, there are alumina PET film 1, nylon (NY) 2, and polyolefin material 3 (CPP) with cohesive...

Embodiment 2

[0057]The difference between this example and Example 1 is that the polyolefin material of the cohesive peeling effect is different.

[0058] Because polypropylene itself is hard and has no sea-island structure, it is easy to be sealed during heat sealing, and the heat sealing strength is very high, which can reach 70N / 15mm or more, but cohesive peeling cannot occur during stretching, which is brittle. fracture. With the addition of polyethylene, a sea-island structure appeared (polypropylene is "sea" and polyethylene is an island), but the compatibility of polypropylene and polyethylene is not good, and with the addition of vinyl elastomer, The compatibility of "island" is improved, and the heat sealing strength is stable. In addition, the amount of polyethylene added should not be too much. Although the film will become more flexible, the unsealing temperature will decrease, which will reduce the heat resistance of the film.

[0059] Based on the above analysis, the corona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| heat seal strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com