Cement road surface impressing equipment

A technology of road surface and embossing equipment, which is applied in the field of imprinting equipment, can solve problems such as complicated operation process and lack of standardization, and achieve the effect of easy device movement and convenient reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

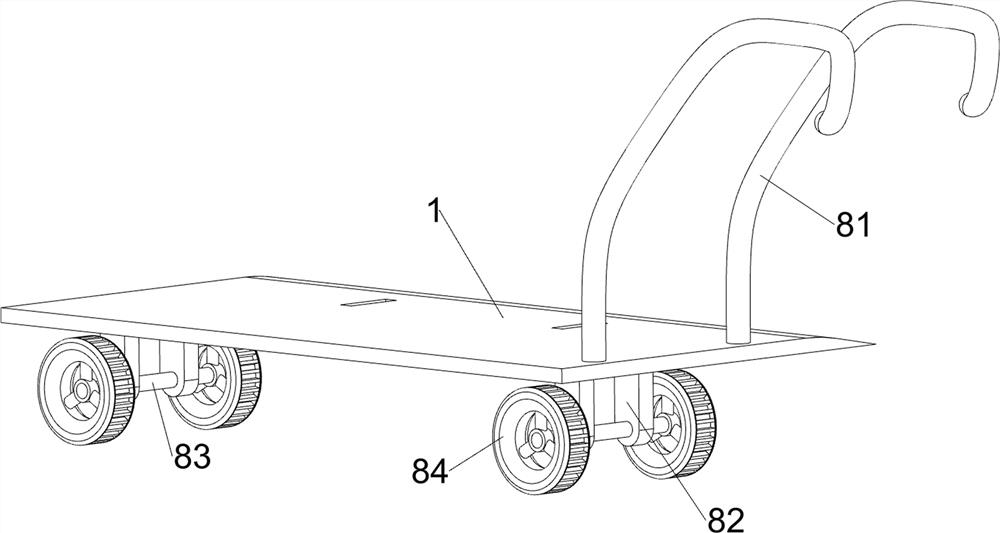

[0061] A cement road surface imprinting equipment, such as figure 1 As shown, it includes a bottom plate 1, a first pole 2, a placement plate 3, a rotating mechanism 4 and an embossing mechanism 5. Two first poles 2 are connected to the upper and lower sides of the bottom plate 1 on the left and right sides. Placement plates 3 are connected between the tops of the first support rods 2 , a rotating mechanism 4 is connected between the upper sides of the placing plates 3 , and an embossing mechanism 5 is rotatably connected to the rotating mechanism 4 .

[0062] When the device needs to be used, the user can turn the embossing mechanism 5 forward, so that the embossing mechanism 5 slides down to contact with the mold, start the rotating mechanism 4, and the rotating mechanism 4 rotates forward to drive the embossing mechanism 5 to move to the right. In order to achieve the purpose of providing driving force for the device, the rotating mechanism 4 continues to rotate forward to ...

Embodiment 2

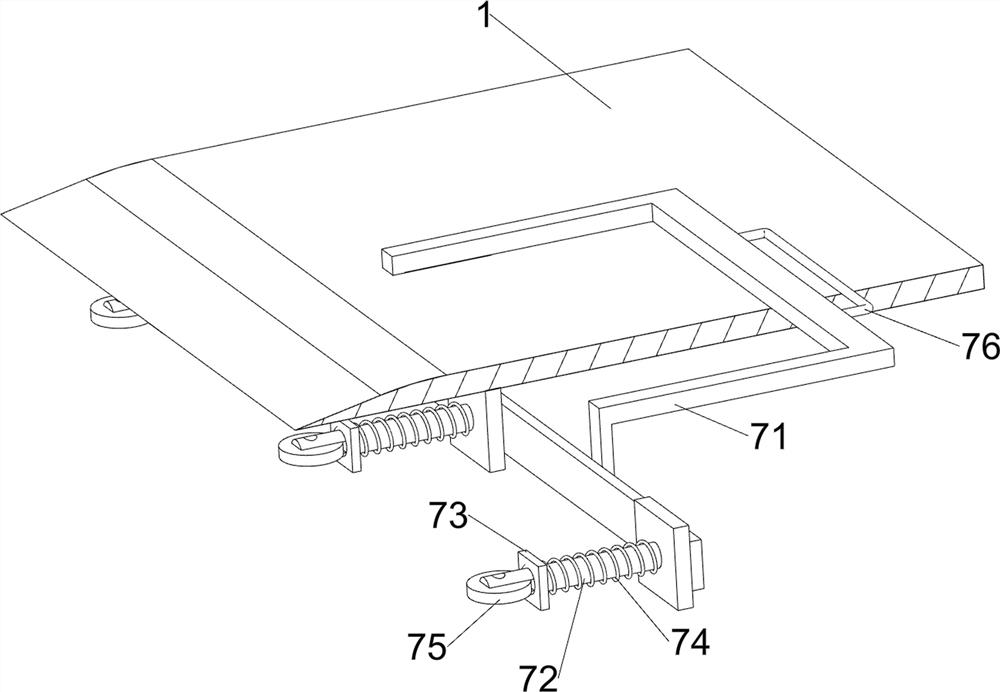

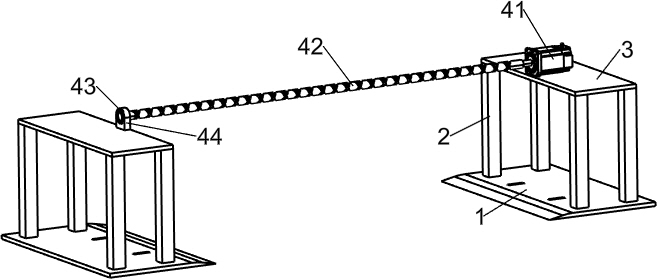

[0064] On the basis of Example 1, such as figure 2 As shown, the rotating mechanism 4 includes a servo motor 41, a twist shaft 42, a bearing 43 and a first fixed block 44, the upper side of the right placing plate 3 is connected with the servo motor 41, and the upper side of the left placing plate 3 is connected with the first fixed block. Block 44, the inner side of the first fixed block 44 is connected with a bearing 43, the output shaft of the servo motor 41 is connected with a twist shaft 42, and the twist shaft 42 is rotationally connected with the bearing 43.

[0065]When the device needs to be used, the user can turn the embossing mechanism 5 forward, so that the embossing mechanism 5 slides down to contact with the mold, start the servo motor 41, and the servo motor 41 rotates forward to drive the twist shaft 42 to move forward in the bearing 43. Rotate, the twist shaft 42 forwardly rotates to drive the embossing mechanism 5 to move to the right, to achieve the purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com