Dredging and scraping well washing device

A technology of well cleaning and pipe scraper, which is applied in wellbore/well parts, cleaning equipment, earthwork drilling and production, etc., and can solve problems such as scraping and cleaning of difficult pipe sections, difficulty in lowering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

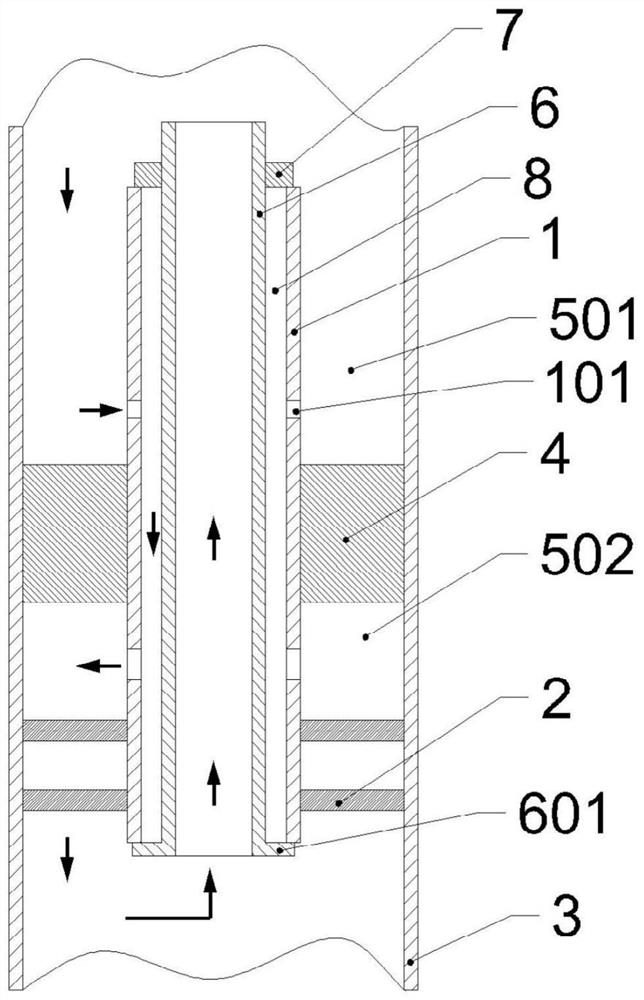

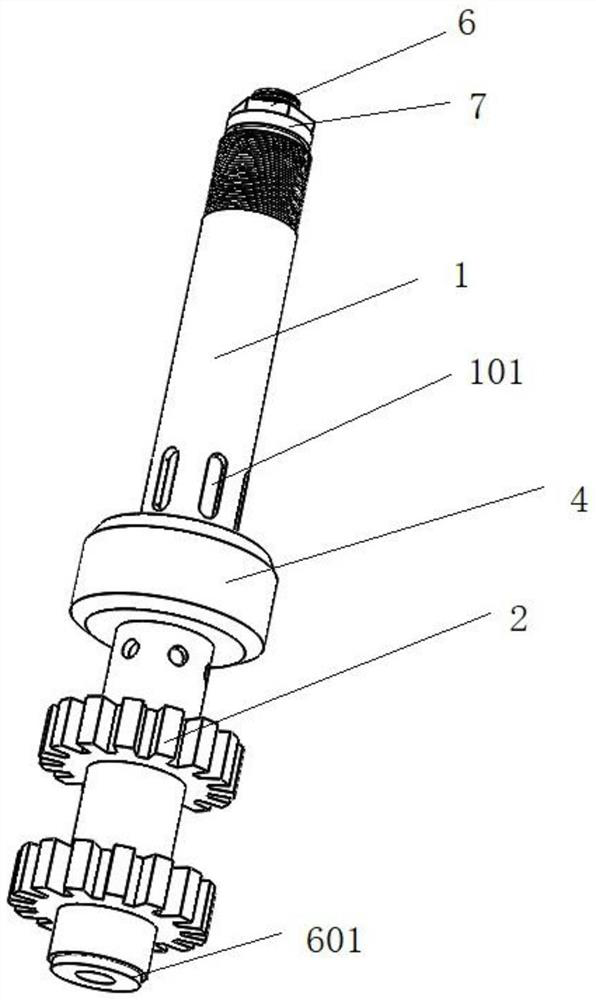

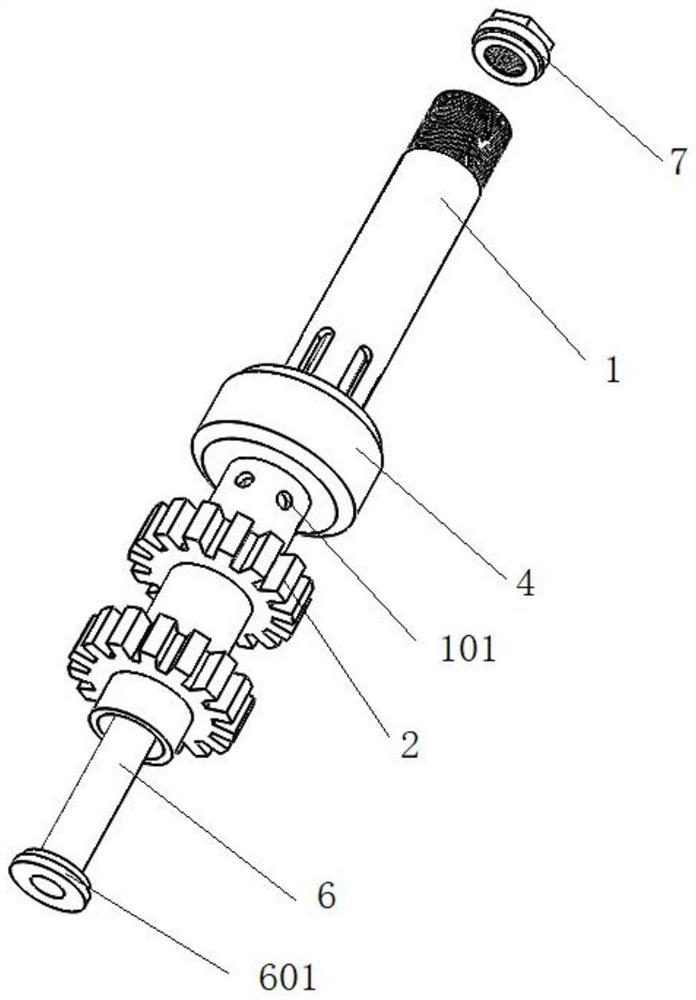

[0017] Please refer to Figure 1-Figure 3 , a kind of through scraping and cleaning device, comprising a central pipe 1 and a scraper 2, the scraper 2 is coaxially sleeved on the outer wall of the central pipe 1, and the side of the scraper 2 is provided with a water tank 201, when in use, One end of the center pipe 1 is connected in series with the tool string (not shown in the figure) and then lowered into the casing 3, and the cleaning liquid is injected from the annular space between the center pipe 1 and the casing 3, and the cleaning liquid passes through the water tank 201 and flows from the center pipe 1 The open end returns to the central pipe 1 and returns to the ground along the tool string; the scraping and flushing device also includes a partition rubber plug 4 and a throttle channel, and the partition rubber plug 4 is coaxially sleeved on the top of the scraper 2 The outer wall of the central pipe 1 is in sliding and sealing connection with the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com