Braking force detection device for vehicle engineering

A detection device and vehicle engineering technology, applied in the field of vehicle detection, can solve problems such as insufficient detection accuracy and insufficient smooth surface, and achieve the effect of assisting the offsetting force of shovel scraping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

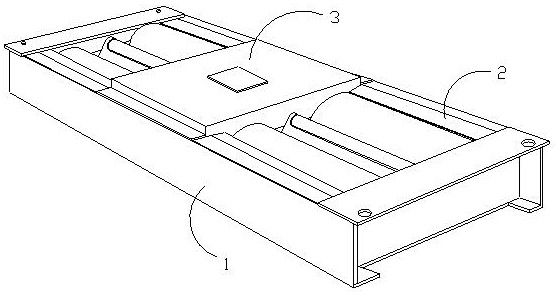

[0031] as attached figure 1 As shown in Appendix 7:

[0032] The invention provides a braking force detection device for vehicle engineering. Its structure is provided with a platform 1, a platform 2, and a detection device 3. The platform 2 is embedded and installed with the platform 1 and is located at the front and rear ends thereof. The device 3 and the stand 1 are of an integrated structure.

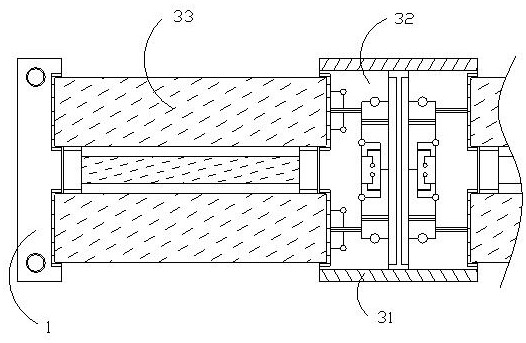

[0033] The detection device 3 is provided with an intermediate plate 31, a detection control box 32, and a drum brake device 33. The intermediate plate 31 and the stand 1 are of an integrated structure, and the detection control box 32 is embedded and installed inside the intermediate plate 31. One side of the drum braking device 33 is embedded in the side end of the middle plate 31 , and the drum braking device 33 is movably matched with the detection control box 32 .

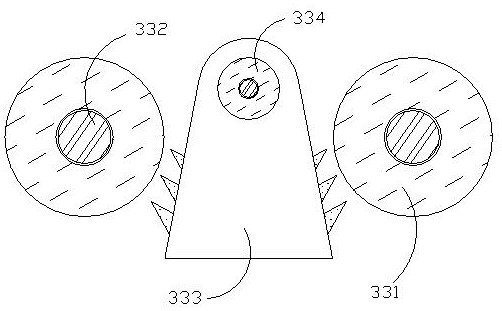

[0034] Wherein, the drum braking device 33 is provided with a drum 331, a roller shaft 332, an intermediate fra...

Embodiment 2

[0041] as attached Figure 8 to attach Figure 9 Shown:

[0042] Wherein, the hemispherical block q3 is provided with a bouncing block q31 and an expansion ball q32, the inner ring q23 is connected with the bouncing block q31 and movably matched, and the bouncing block q31 is connected to the rear end of the scraping block q1, so The expansion and contraction ball q32 is in clearance fit with the inner side of the elastic block q31. The elastic block q31 is arc-shaped and has good elasticity. The expansion and contraction ball q32 is spherical and can be changed in size. The elastic block The q31 cooperates with the expanding and contracting ball q32 to make the hemispherical block q3 elastically deform in a hemispherical state, which is convenient to assist and drive the position change of the scraping block q1.

[0043] Wherein, the expansion and contraction ball q32 is provided with a tough block w1, a weighted ball w2, and a telescopic frame w3. The frame w3 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com