Positioning device of medical imaging equipment

A medical imaging and positioning device technology, which is applied in the direction of mechanical equipment, supporting machines, machine tables/supports, etc., can solve the problems of inability to adjust the vertical and horizontal positions of medical imaging equipment, increase the workload of staff, and adjust medical imaging equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

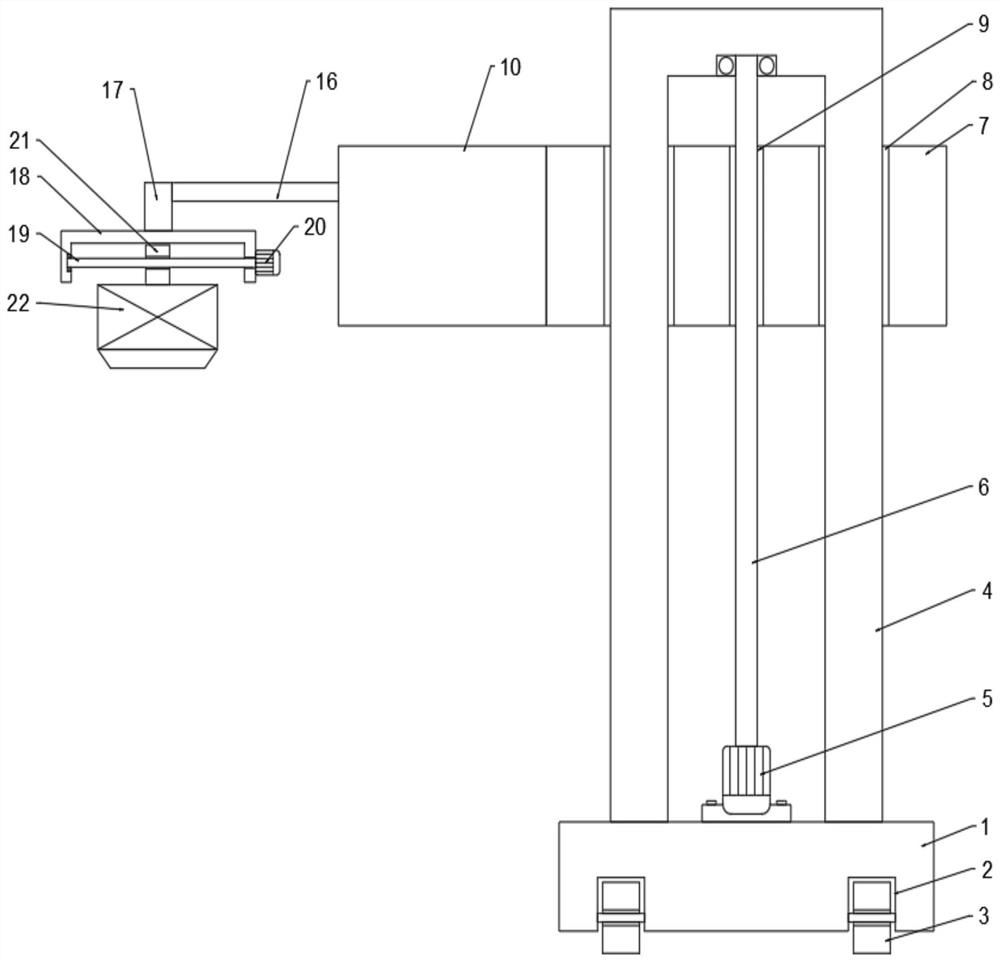

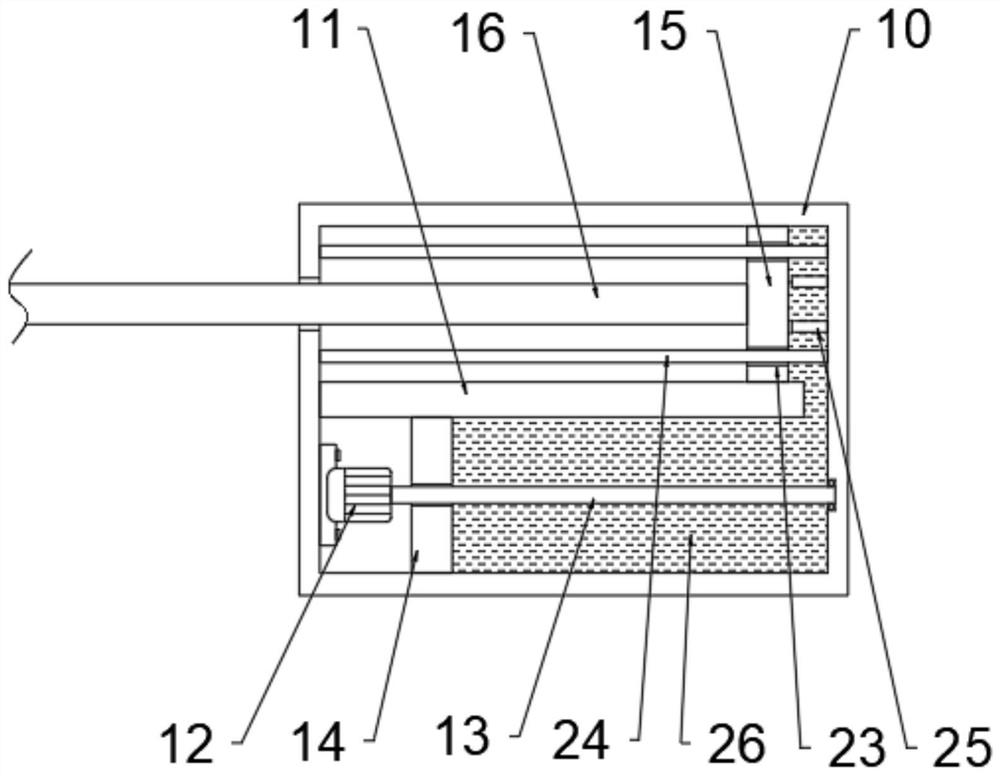

[0029] see Figure 1 ~ Figure 3 , a positioning device for medical imaging equipment, comprising a moving base 1, a bracket 4 is vertically welded on the upper part of the moving base 1, a lifting plate 7 is arranged on the outside of the bracket 4, and the upper part of the moving base 1 passes through a lifting assembly and a lifting plate 7, the side wall of the lifting plate 7 is welded with a connection box 10, the inside of the connection box 10 is provided with a horizontal position adjustment assembly, and a connection block 17 is fixedly installed on one side of the horizontal position adjustment assembly, and the connection block The bottom of the 17 is connected with the medical imaging device 22 through a fine-tuning assembly.

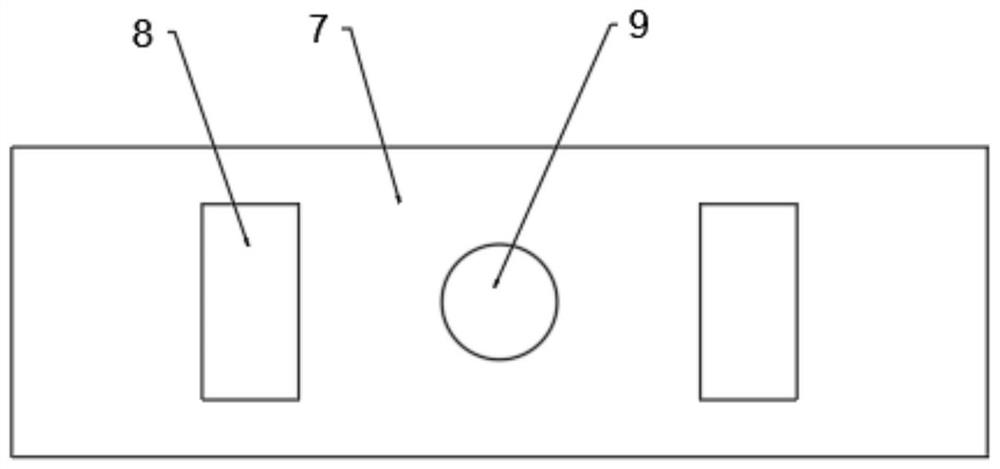

[0030] The lifting assembly includes a first motor 5, a first leading screw 6, a through hole 8 and a threaded hole 9, the upper part of the moving seat 1 in the middle of the support 4 is fixedly installed with a first motor 5, and the out...

Embodiment 2

[0037] see Figure 1 ~ Figure 4 , as a positioning device for medical imaging equipment in Example 1, including a moving base 1, a bracket 4 is vertically welded on the upper part of the moving base 1, and a lifting plate 7 is provided on the outside of the bracket 4, and the upper part of the moving base 1 Connected with the lifting plate 7 through the lifting assembly, the side wall of the lifting plate 7 is welded with a connection box 10, the inside of the connection box 10 is provided with a horizontal position adjustment assembly, and a connection block is fixedly installed on one side of the horizontal position adjustment assembly 17. The bottom of the connecting block 17 is connected to the medical imaging device 22 through a fine-tuning assembly.

[0038] Different from Embodiment 1, the inside of the lifting plate 7 is symmetrically provided with a fixing groove 27, and a positioning assembly is arranged in the fixing groove 27, and the positioning assembly includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com