Two-box type high and low temperature impact test box

A technology of impact test chamber and high temperature test chamber, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of increasing the temperature of the low temperature test chamber, reducing the temperature of the high temperature test chamber, and high operating costs, avoiding manual labor and increasing energy. Loss and deformation prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

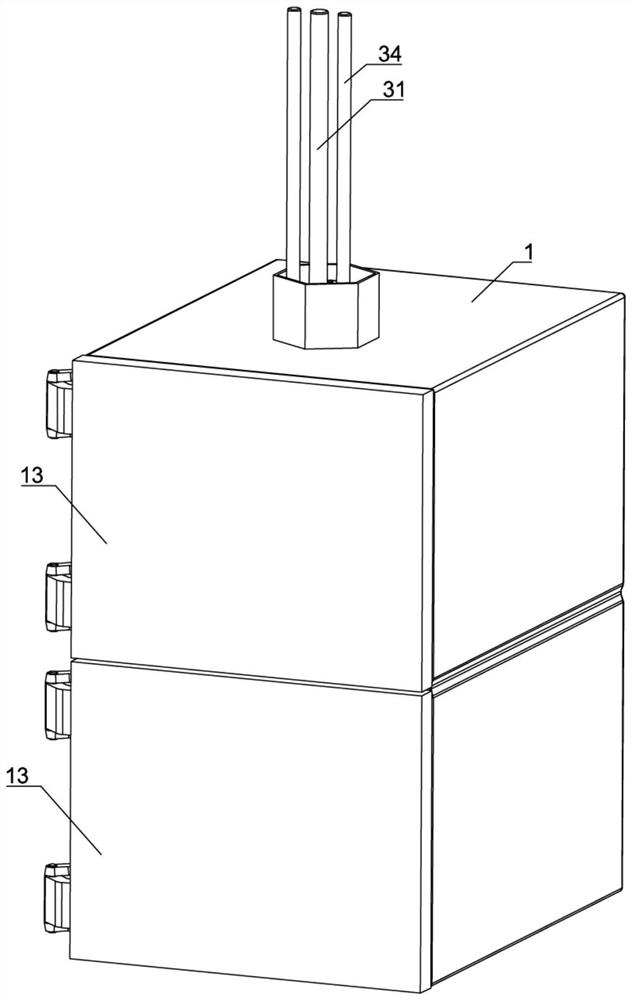

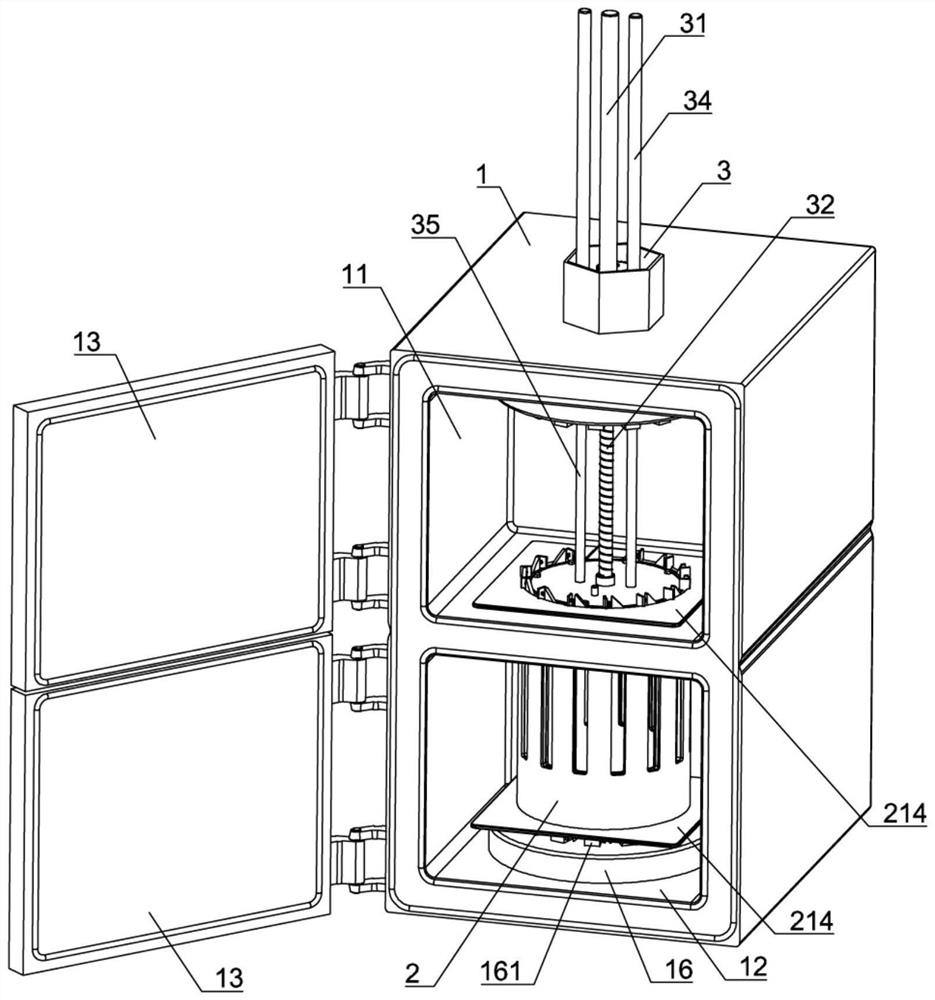

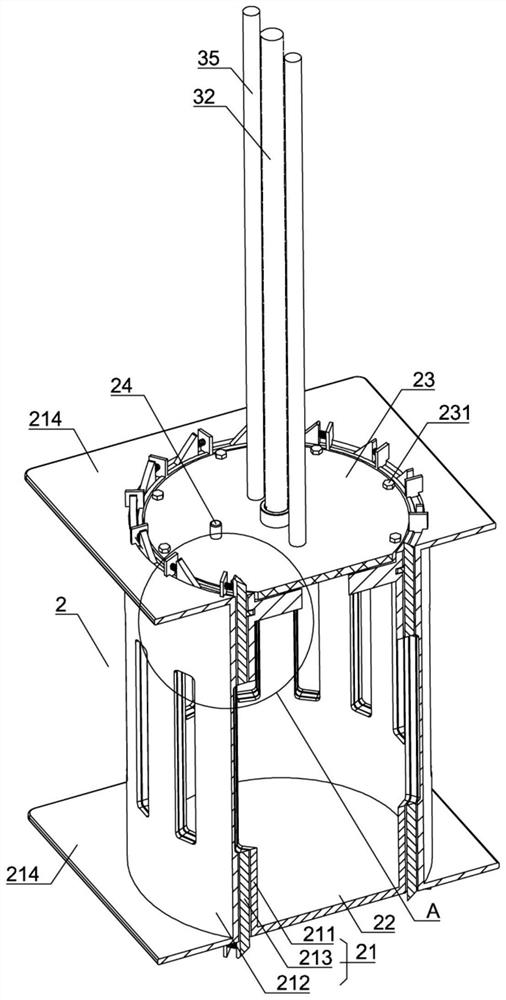

[0032] like Figure 1-Figure 6 As shown, a two-box type high and low temperature impact test box of the present invention includes an outer box body 1, and the front end of the outer box body 1 includes a low temperature test box 11 and a high temperature test box 12 arranged up and down, a low temperature test box 11 and a high temperature test box. The boxes 12 are equipped with a box door 13, and the rear end of the outer box body 1 is provided with a refrigeration unit and a heating unit arranged up and down, and a spacer 14 is provided between the low temperature test chamber 11 and the low temperature test box 12, and the spacer 14 is provided with a circle. The slot 15 and the circular slot 15 are slidingly connected with a circular l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com