Rigidity measuring and calculating method for hollow floor with built-in corrugated cylinders

A hollow floor, corrugated technology, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of lack of simultaneous consideration, incomplete development of structural internal force calculation formulas, and incomplete theoretical results, and achieves detailed theoretical research. , The effect of force performance science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

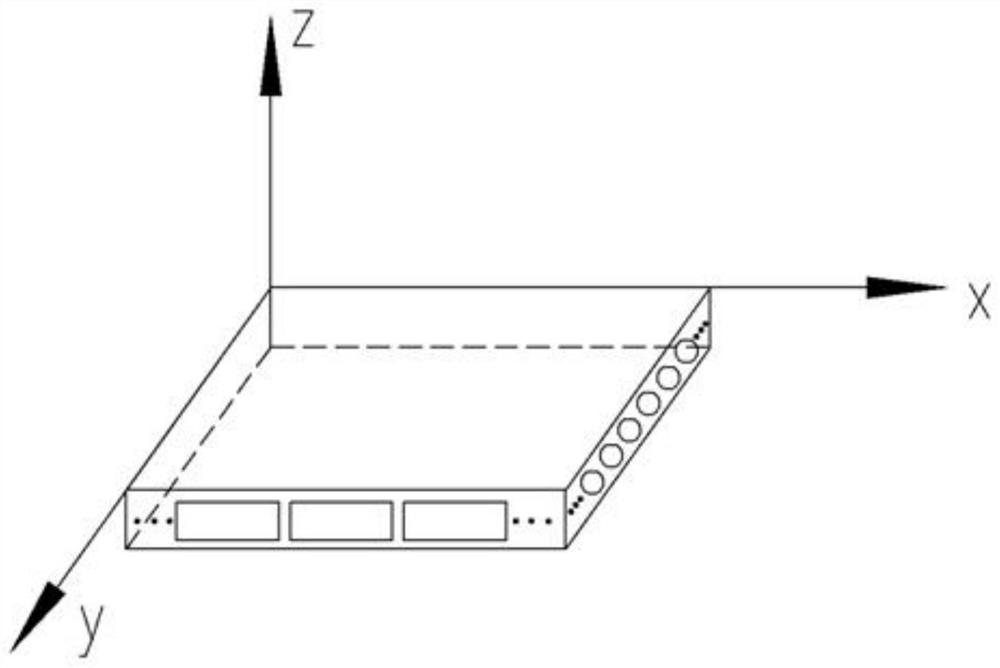

[0070] Built-in corrugated cylindrical hollow floor cover stiffness measuring method, combined with thin wall corrugated cylinders, the structural characteristics of concrete hollow cover, introduced into the Cartesian coordinate system, establish hollow floor coordinates figure 1 As shown, Oz is above the OXY coordinate plane, assuming that Y is parallel to the tube axis direction, and X is perpendicular to the tube axial direction.

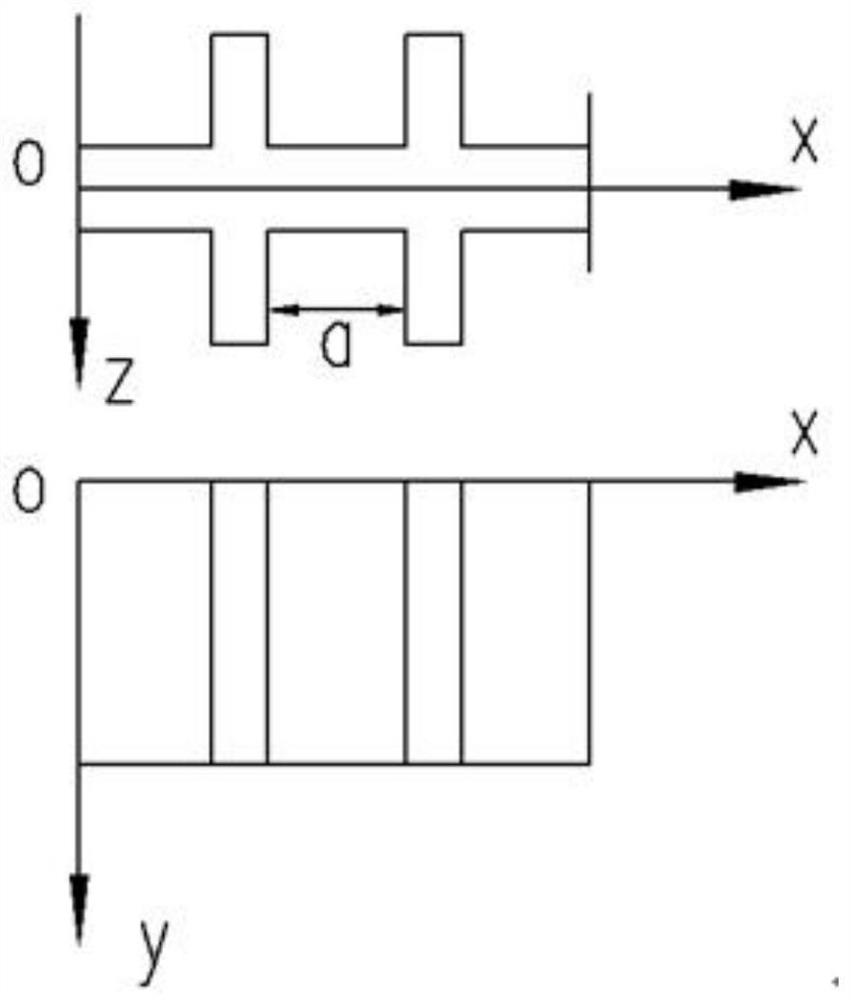

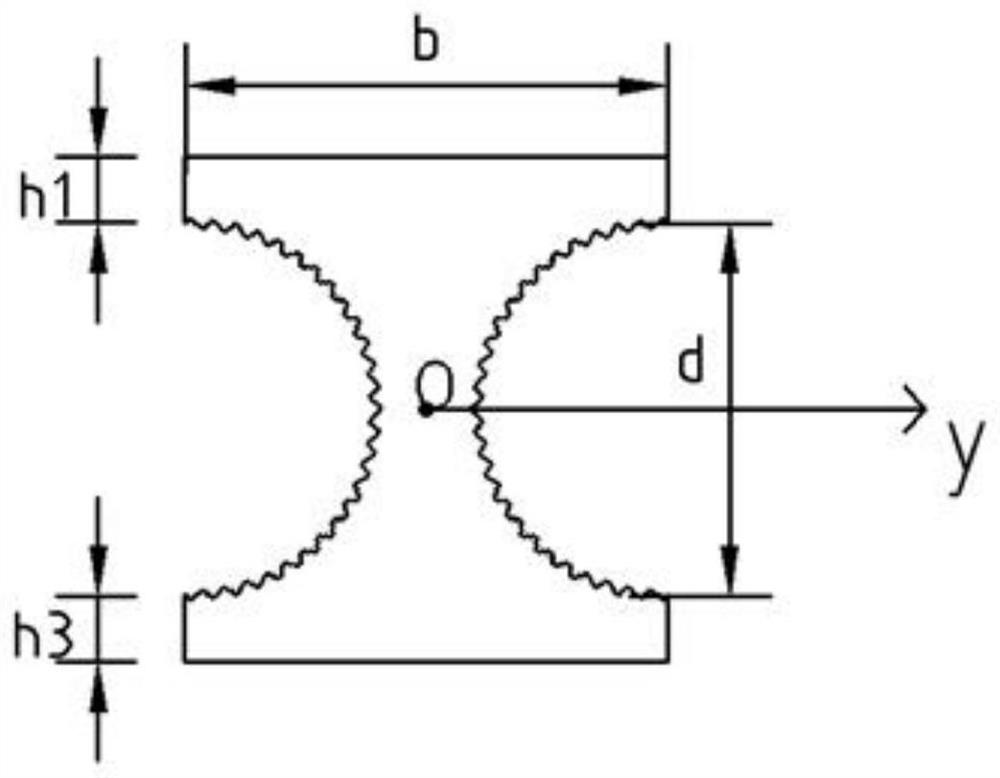

[0071] The web part is regarded as a rib into the wing edge, figure 2 For the use of ribbed

[0072] Schematic, formula (3.1) is a rigidity theoretical formula

[0073]

[0074] In the formula, e is the concrete elastic modulus, E 'is the elastic modulus of the rib, and the spacing of the ribs, and I' is the cross-sectional moment of the rib, and μ is the Poisson ratio of concrete, δ is a plate thickness.

[0075] The X-direction and y direction of the built-in thin-walled corrugated cylindrical hollow floor can be constructed as a plurality of eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com