Four-way explosion-proof junction box

An explosion-proof junction box and junction box technology, which is applied in the field of junction boxes, can solve the problems of wire connectors being pulled apart, poor working reliability, and inconvenient replacement of explosion-proof boxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

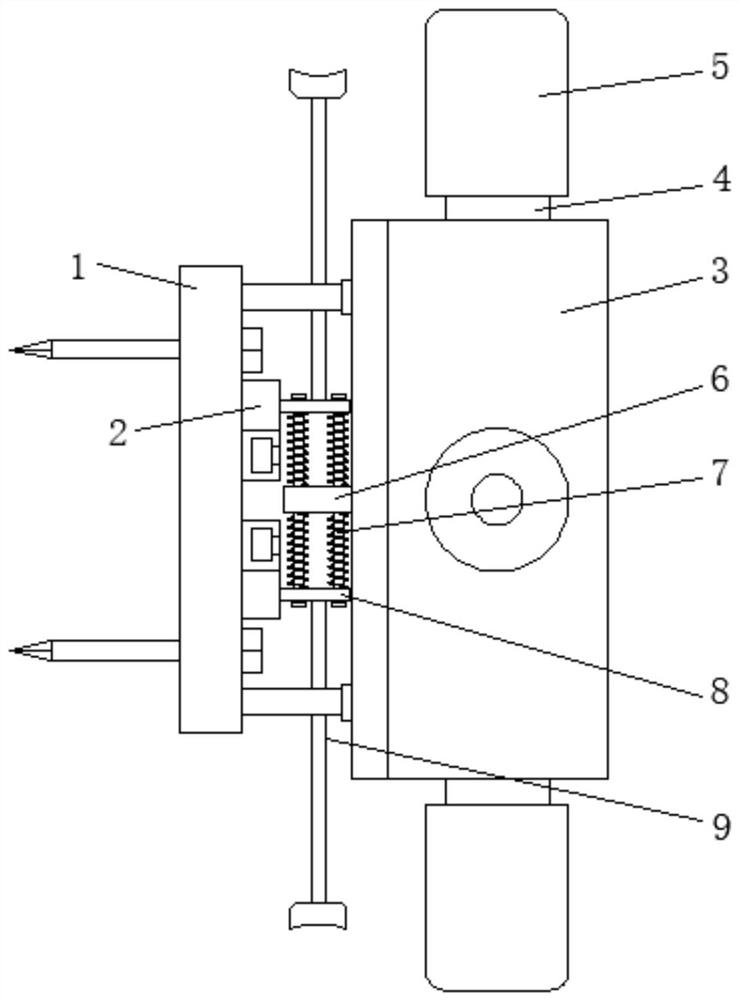

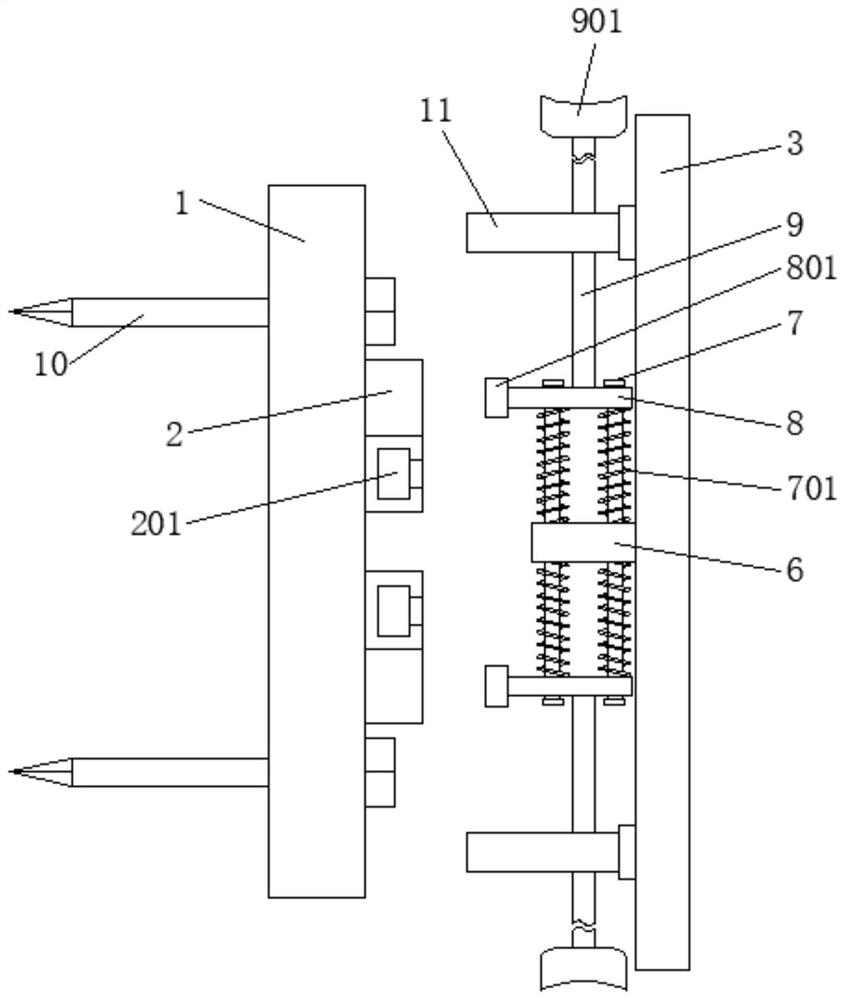

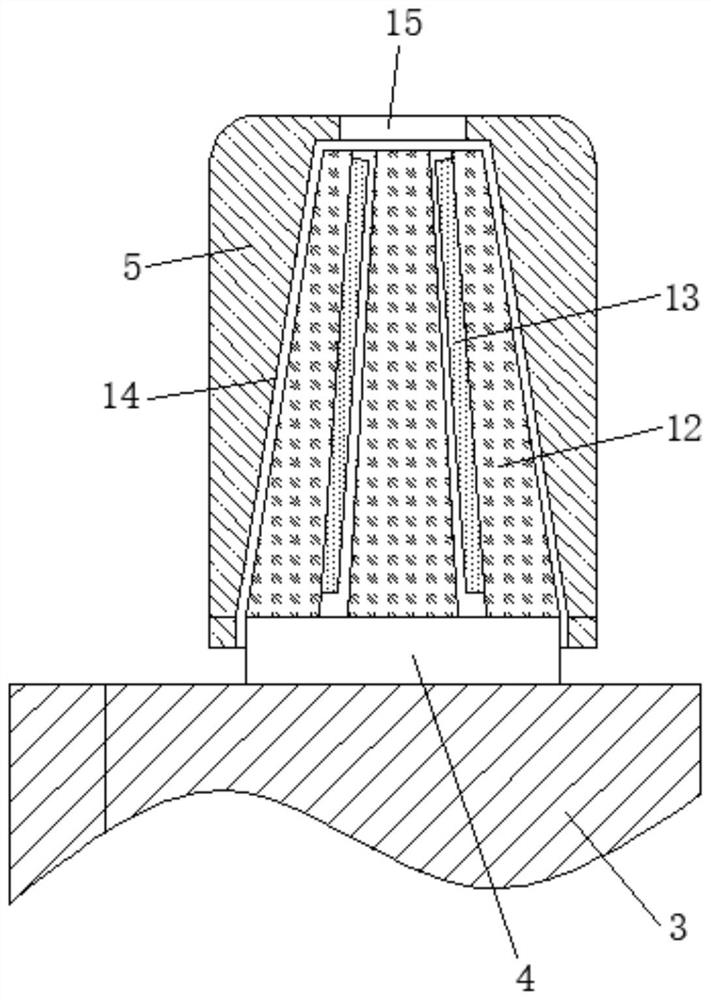

[0021] Embodiment one, by figure 1 , figure 2 and image 3 Given, the present invention includes a mounting plate 1, two L-shaped clamping plates 2 are fixedly installed in the middle of one side of the mounting plate 1, through the setting of the L-shaped clamping plates 2, the moving block 8 can be effectively fixed, and the mounting plate 1 One side of the terminal box body 3 is provided with a junction box body 3, and the middle part of the four sides of the junction box body 3 is provided with a connection port 4, and one end of the connection port 4 is movably connected with a fastening nut 5, and the middle part of one end of the junction box body 3 is fixedly installed with a fixed Block 6, the middle part of the fixed block 6 is fixedly connected with two slide bars 7, through the setting of the slide bar 7, the moving block 8 can be effectively moved, and the two ends of the two slide bars 7 are movably socketed to move Block 8, one end of the two moving blocks 8 ...

Embodiment 2

[0022] Embodiment two, on the basis of embodiment one, by figure 2 Given, the four corners of the mounting plate 1 are provided with fixing nails 10, and the middle parts of the two L-shaped clamping plates 2 are provided with L-shaped sliding slots 201. Through the setting of the fixing nails 10, the mounting plate 1 can be effectively fixed. Fixed installation.

Embodiment 3

[0023] Embodiment three, on the basis of embodiment one, by figure 2 Given, the four corners of one end of the junction box body 3 are fixedly connected with supporting legs 11, and one end of the four supporting legs 11 is in contact with the side of the mounting plate 1, through the setting of the supporting legs 11, the junction box body 3 After being installed on the mounting board 1, it can be effectively kept stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com