Calibration method of fixed-torque impact wrench

A technology of impact wrench and calibration method, which is applied in the direction of wrench, force/torque/power measuring instrument calibration/test, screwdriver, etc., and can solve the problem of inaccurate constant torque control mode, unfixed nut screwing position, and working starting point of impact wrench Uncertainty and other problems, to achieve the effect of conveniently outputting accurate torque and ensuring accurate control

Active Publication Date: 2021-06-25

河南牛帕力学工程研究院

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In short, the rotation angle of each part in the action of the impact wrench is recorded by the angle sensor, so as to calculate the total output angle A of the impact wrench. When the output angle is equal to the preset output angle B, it is considered that the impact wrench has reached When the corresponding output torque is reached, the output wrench is controlled to stop working. The fundamental problem of the existing impact wrench is that each preset output angle B does correspond to a calculated output angle A of the torque wrench, but this requires, When the impact wrench impacts each nut, the position of each nut relative to the bolt is consistent with the position of the nut relative to the bolt during the setting process. The basic operation method is to manually screw the nut until the nut is relatively clamped and the bolt cannot When turning, the impact wrench can be used to operate. There are two problems in this operation. 1.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

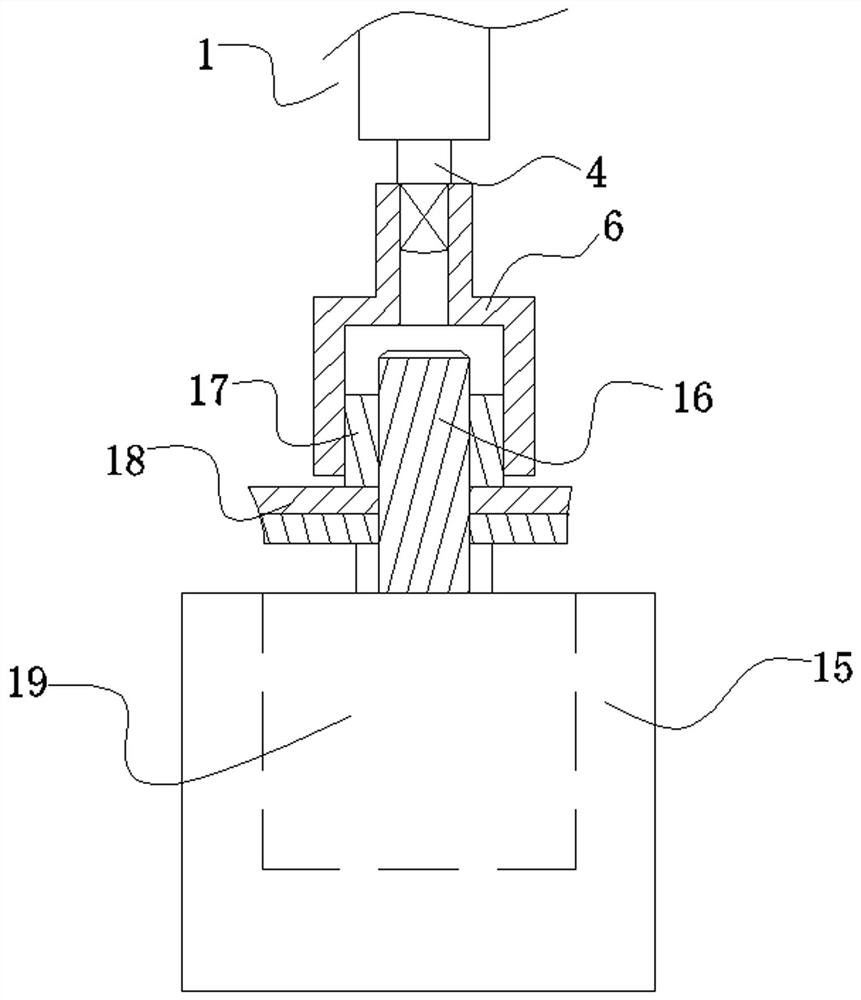

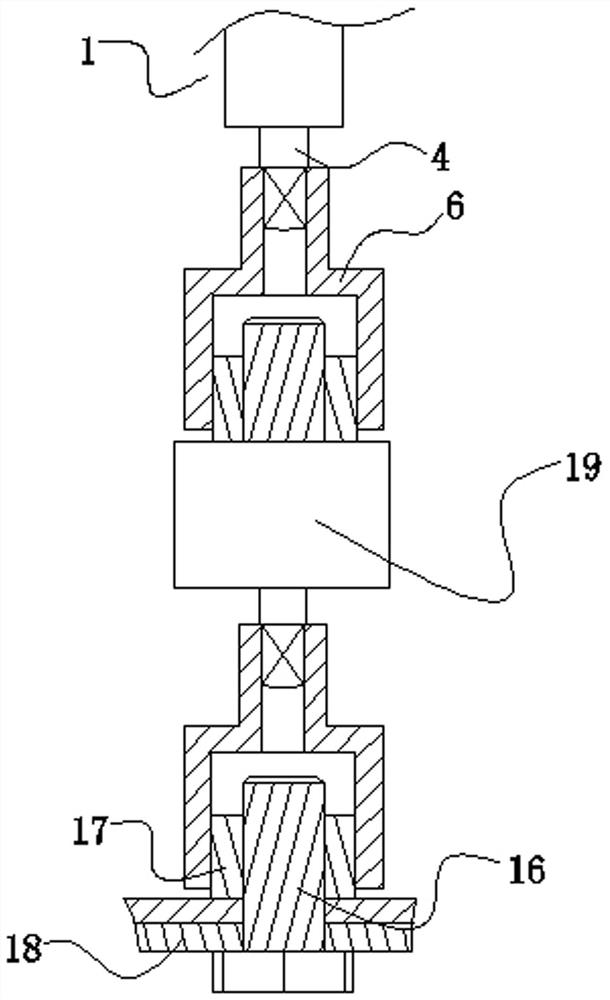

[0026] The torque test device in embodiment 2 also comprises test device bolt 16, test device nut 17, simulation holder 18 and torque sensor 19, just difference is, during use, torque sensor 19 is connected with test device nut 17 and impact wrench 1 Between the output shafts of the impact wrench to measure the rotational torque between the nut and the bolt, that is, the output torque generated by each impact of the impact wrench.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

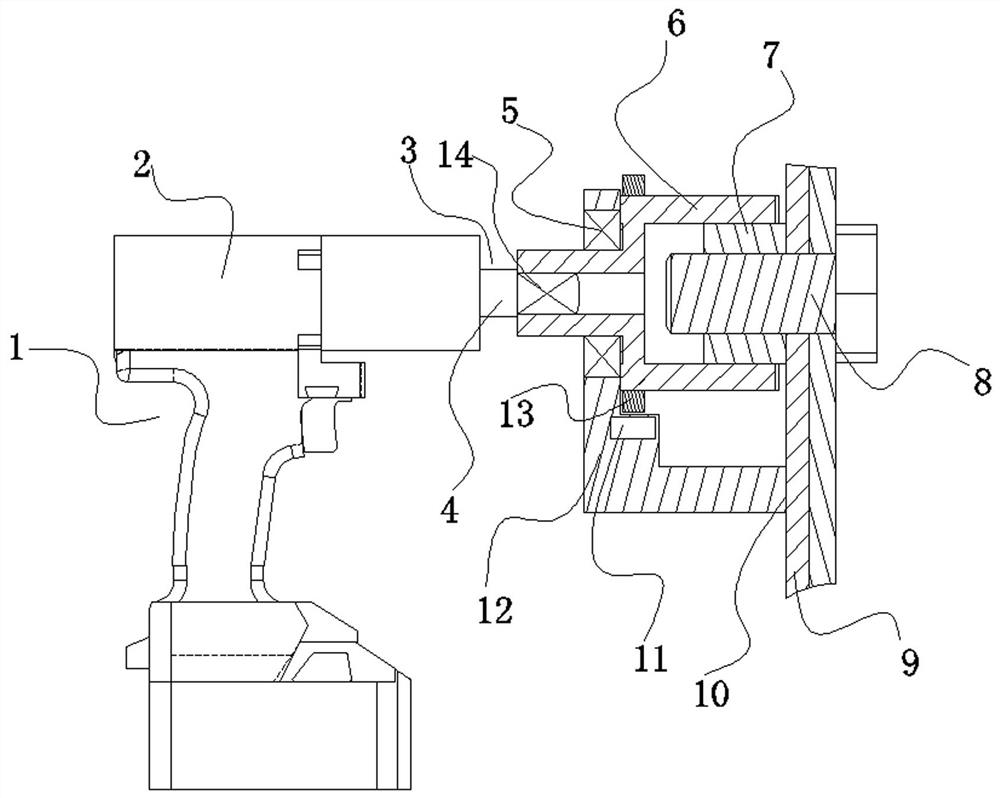

The invention relates to a calibration method of a fixed-torque impact wrench. The fixed-torque impact wrench is used to carry out an impact test on a torque test device, the torque test device comprises a test device bolt, a test device nut and a torque sensor, in the impact process of the fixed-torque impact wrench on the test device bolt or the test device nut, an angle sensor of the fixed-torque impact wrench measures rotation angular displacements B1, B2,..., Bn of an output shaft of the fixed-torque impact wrench when the fixed-torque impact wrench impacts each time, the torque sensor measures rotation torques T1, T2,..., Tn of the test device nut relative to the test device bolt when the fixed-torque impact wrench impacts each time, and when the rotation angular displacement of the output shaft are Bn in the nth impact of the fixed-torque impact wrench, the output torque of the impact wrench is Tn. The invention provides the calibration method for calibrating the fixed-torque impact wrench and capable of representing output torque by single-rotation angular displacements.

Description

technical field [0001] The invention relates to a calibration method for a constant torque impact wrench in the calibration field. Background technique [0002] In various fields such as iron towers, bridges, railways, and equipment manufacturing, it is faced with tightening nuts and bolts, and it is necessary to ensure that the torque between the nuts and bolts reaches the set torque. Therefore, constant torque wrenches are widely used and very necessary. [0003] There are two types of traditional wrenches, one is a continuous output wrench, and the other is an impact wrench. The output shaft of the continuous output wrench rotates continuously with the nut until it is locked, and the nut and the output shaft maintain a linkage relationship. The constant torque of the wrench is relatively easy to realize. It is only necessary to install a corresponding torque sensor on the output shaft to directly read the torque of the nut. However, due to the continuous output of this t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B25B23/14G01L25/00

CPCB25B23/14B25B23/1405G01L25/00G01L25/003

Inventor 罗宇亮尚廷东李君章刘建锋

Owner 河南牛帕力学工程研究院

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap