Shaping tool for motorcycle accessory production

A technology for motorcycles and accessories, applied in the field of plastic tooling for the production of motorcycle accessories, can solve the problems of prolonging the plastic tooling time, reducing the production efficiency of plastic parts, and low natural heat dissipation and heat dissipation efficiency, so as to shorten the shaping time and improve the convenience. , the effect of short cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

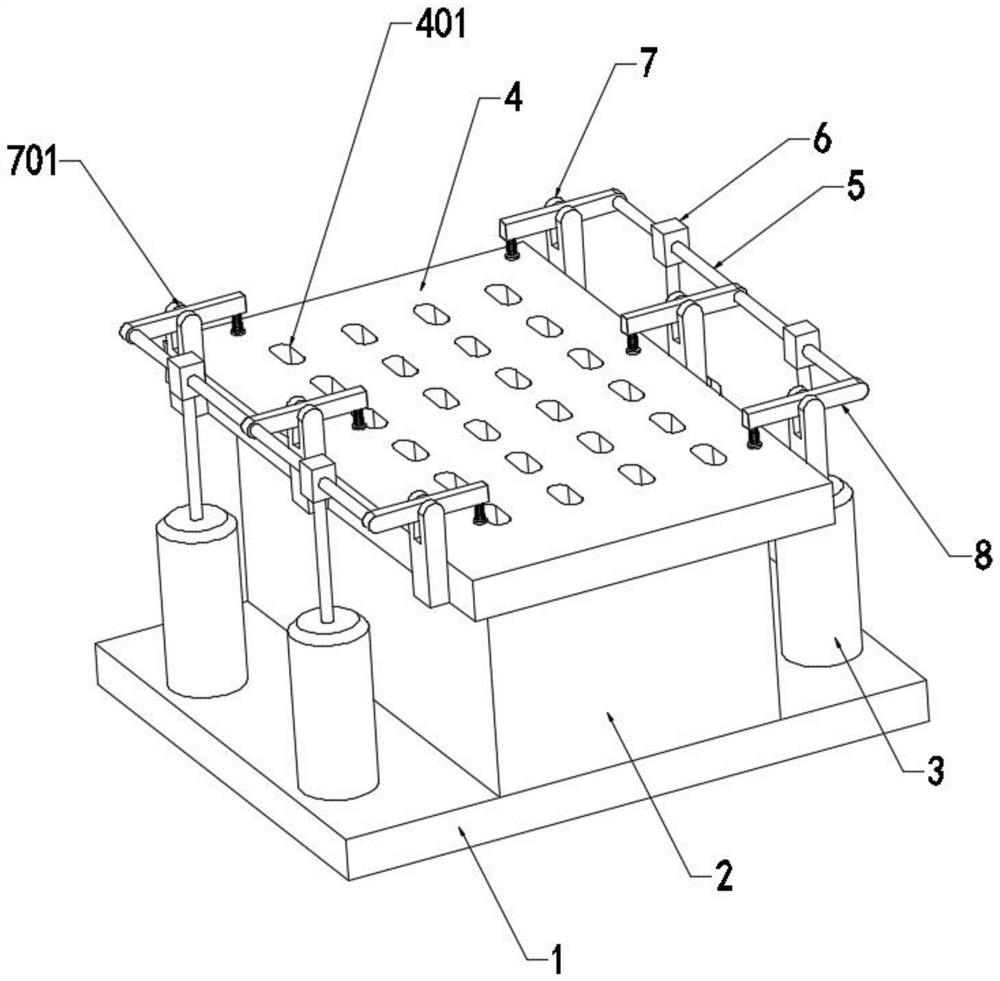

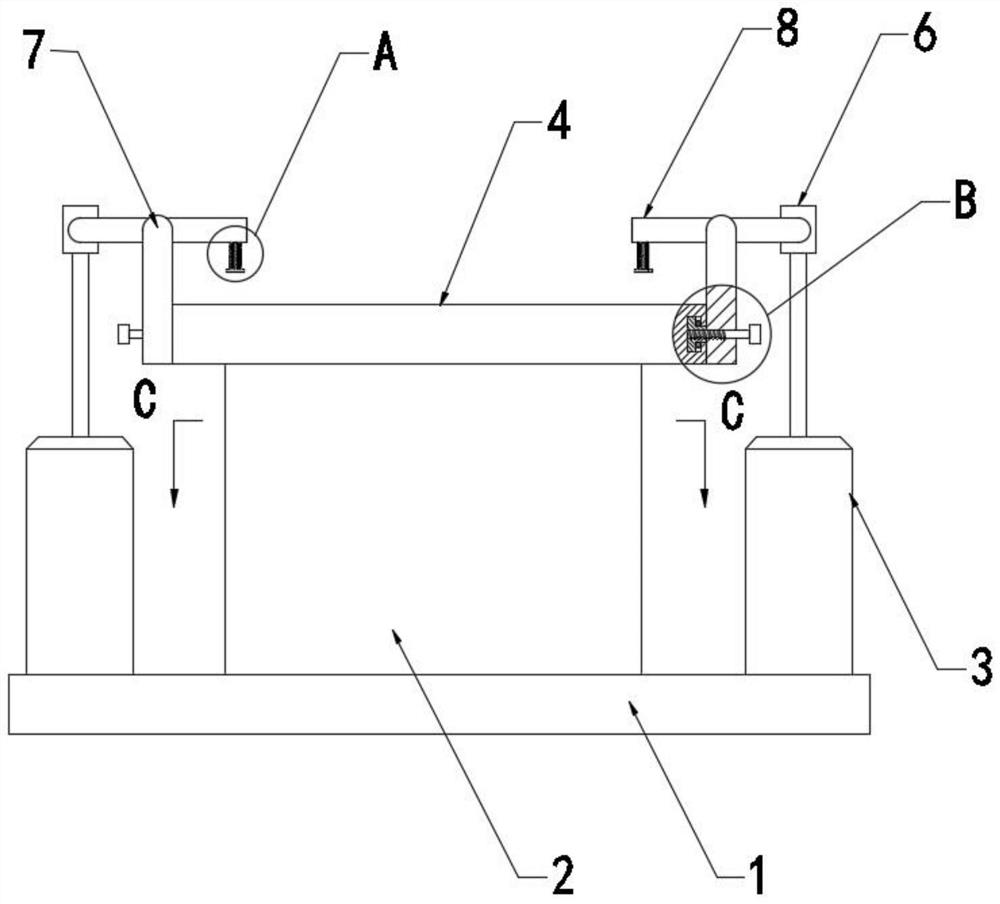

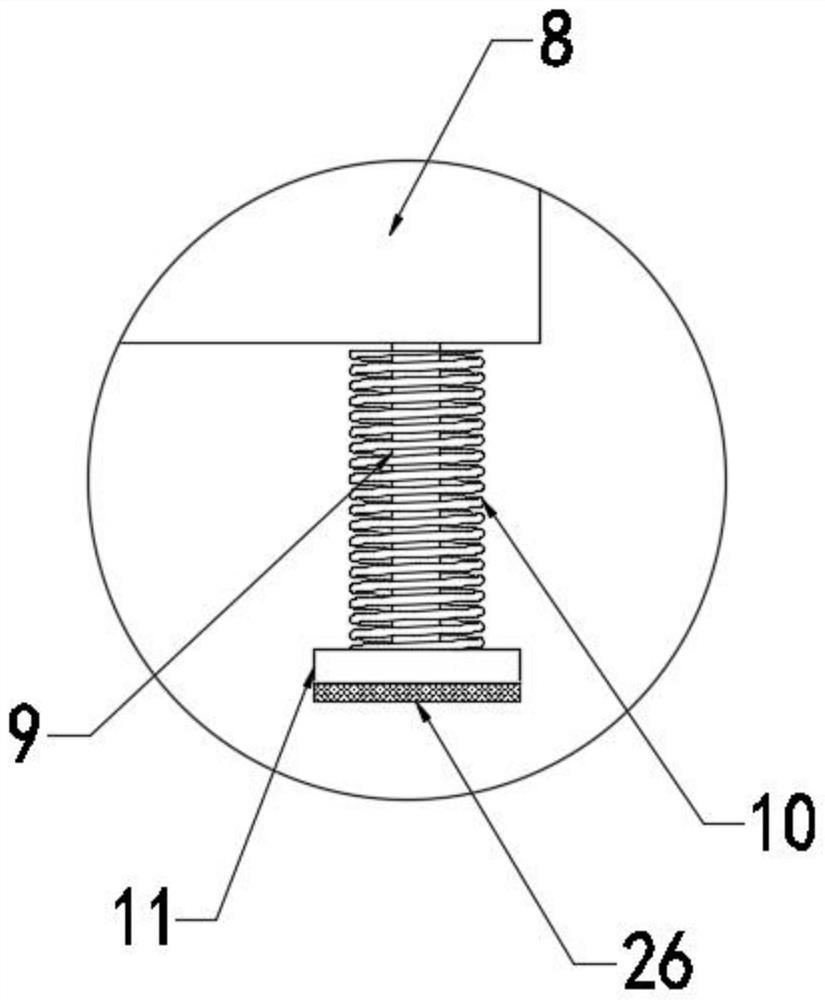

[0042] see Figure 1-6, the present invention provides a technical solution: a shaping tool for the production of motorcycle parts, including a bottom plate 1, an installation shell 2 is fixedly installed on the top of the bottom plate 1, a shaping plate 4 is fixedly installed on the mounting shell 2, and there is a A plurality of ventilation holes 401, a plurality of ventilation holes 401 are arranged at equal intervals in the shaping plate 4, a plurality of first moving blocks 7 are fixedly installed on both sides of the shaping plate 4, and a plurality of first moving blocks 7 are mounted on the shaping plate 4, etc. The spacing is set, a groove 701 is provided in the first moving block 7, a rotating block 8 is installed in the groove 701, and a driving rod 5 passing through the rotating block 8 is provided on both sides of the shaping plate 4, and the driving rod 5 and the rotating block 8 Sliding connection, a plurality of installation blocks 6 are fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com