Nickel plating wastewater treatment device

A treatment device and wastewater technology, which is applied in metallurgical wastewater treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of cumbersome nickel plating wastewater treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to set forth the specific implementation steps of the present invention more vividly, it will be further described as follows in conjunction with the accompanying drawings:

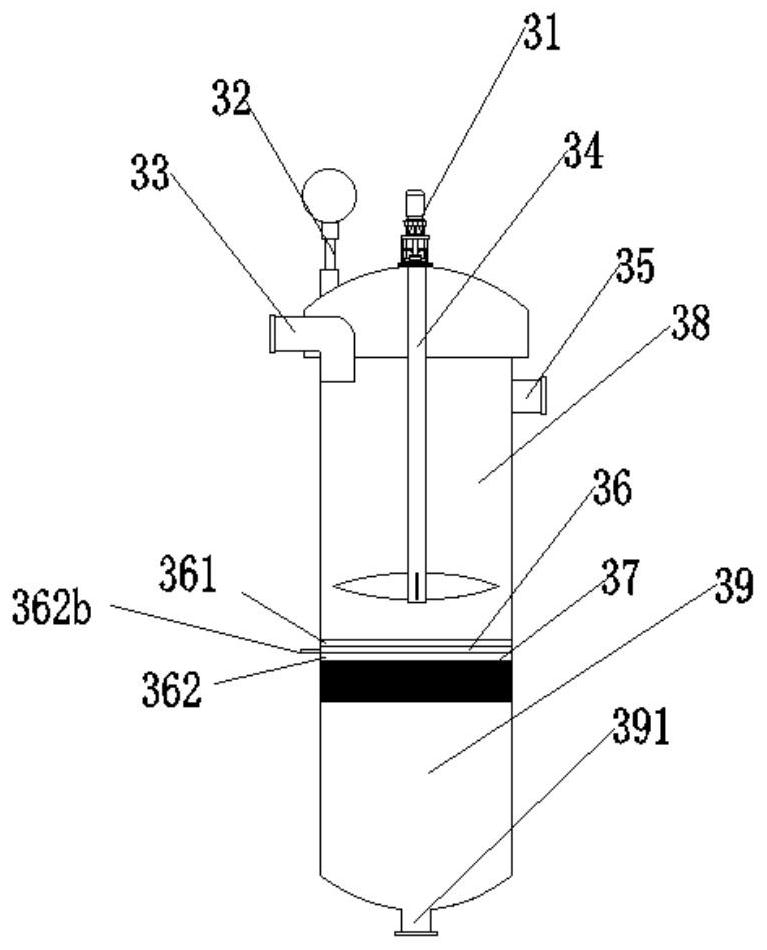

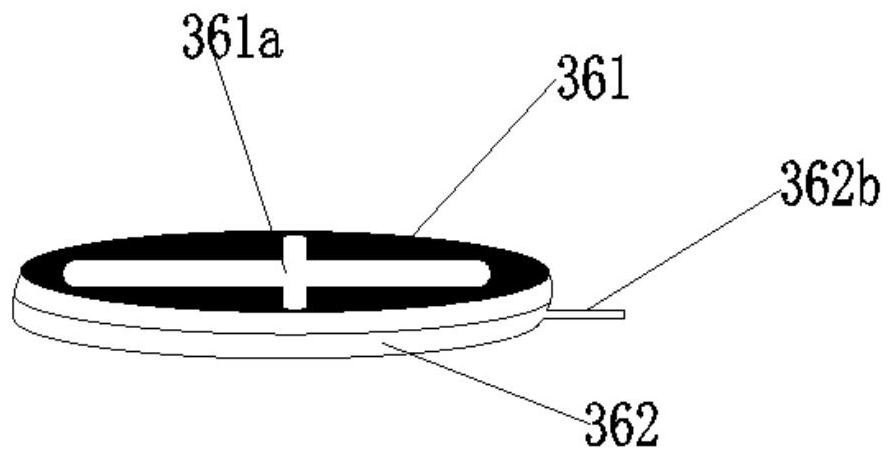

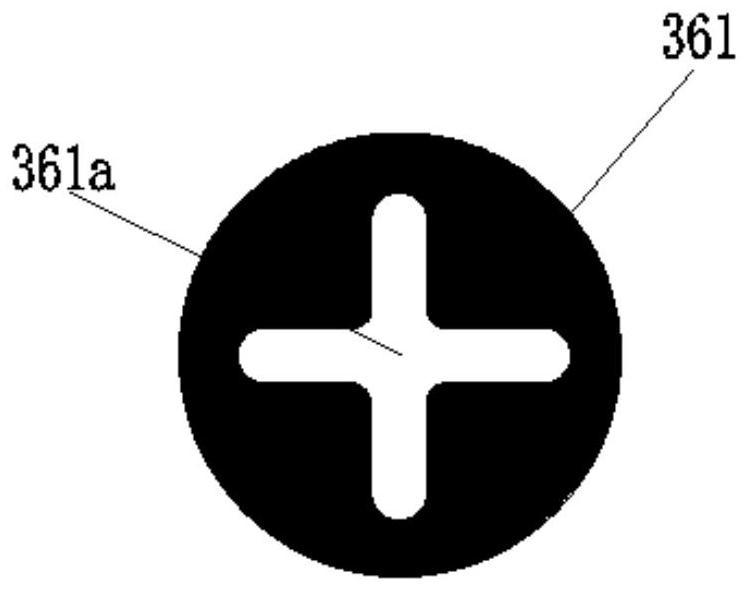

[0019] With reference to accompanying drawing, a kind of treatment device of nickel-plating waste water comprises the first feed inlet 10, feed pump 20, processor 30, high-pressure pump device 40, filtering device 50 and cleaning tank 60, nickel-plating waste water enters from the first The feed port 10 enters the processor 30 through the feed pump 20 to obtain a primary waste liquid, and the primary waste liquid enters the filter device 50 from the processor 30 through the high-pressure pump device 40, and the obtained clear liquid enters the cleaning tank 60 from the filter device 50, and the clear liquid enters the cleaning tank 60 from the filter device 50. The cleaning tank 60 enters the treatment device through the feed pump 20. The processor 30 includes a first chamber 38 and a secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap