High-quantum-yield copper nanocluster fluorescent nanoflowers and preparation method and application thereof in LEDs

A fluorescent nanometer and copper nanotechnology, applied in the fields of nano optics, nanotechnology, nanotechnology, etc., can solve the problem of low fluorescence quantum yield of copper nanocluster fluorescent materials, difficult to directly apply to the LED field, and copper nanocluster quantum yield. problems such as low rate, to achieve the effect of excellent luminous intensity, unique properties and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

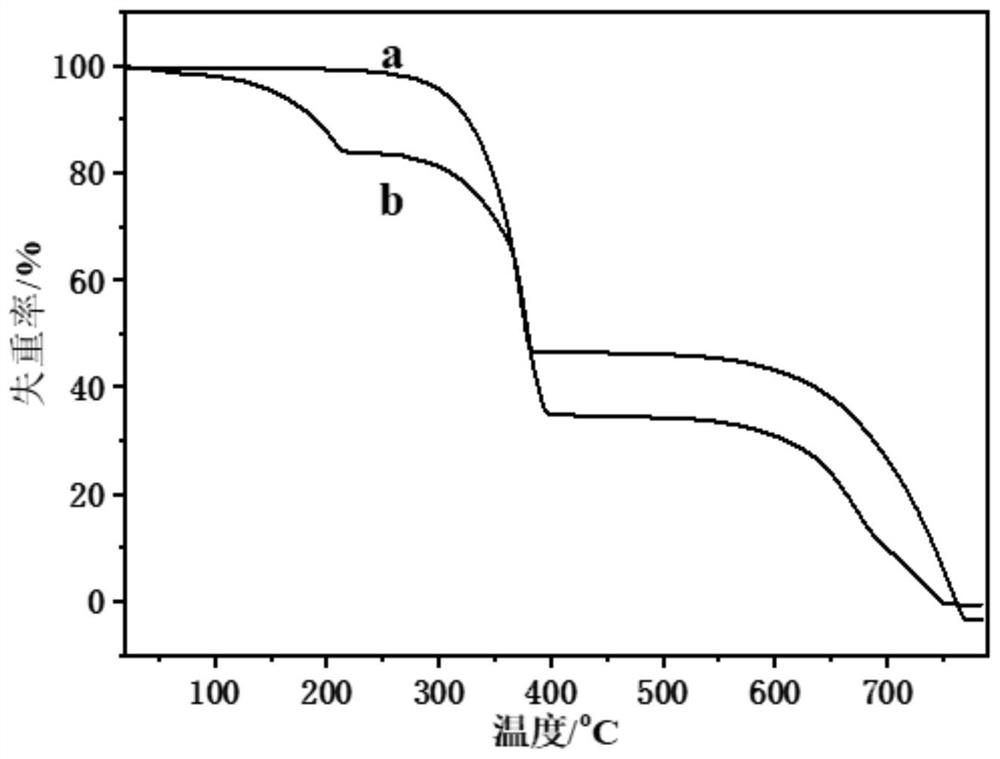

[0074] A method for preparing fluorescent nanoflowers of copper nanoclusters, comprising the following steps:

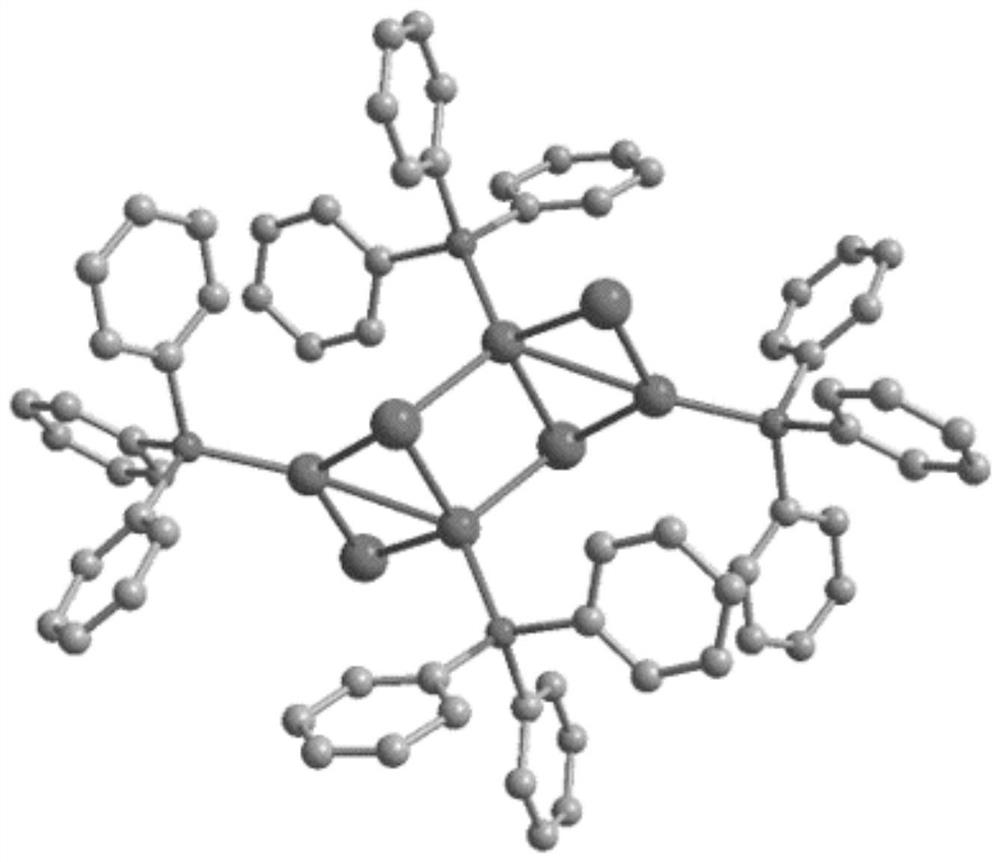

[0075] (1)Cu 4 I 4 Synthesis

[0076] Disperse CuI (500mg, 2.6mmol) in dichloromethane solution, stir for 10min, add triphenylphosphine (524mg, 2.0mmol) to the miscible solution, stir well at room temperature for 2 hours, and filter with suction to obtain a white powder solid. The above-mentioned white powdery solid is added in excessive acetonitrile solution, ultrasonic, excess CuI is removed, suction filtration, acetonitrile washing, obtain pure white powdery solid. Take 10 mg of the above-mentioned pure white solid powder and dissolve it in 2 mL of dimethyl sulfoxide solution, add it to a diffusion glass tube, add 2 mL of methanol solution to the upper layer to diffuse, and obtain Cu 4 I 4 powder.

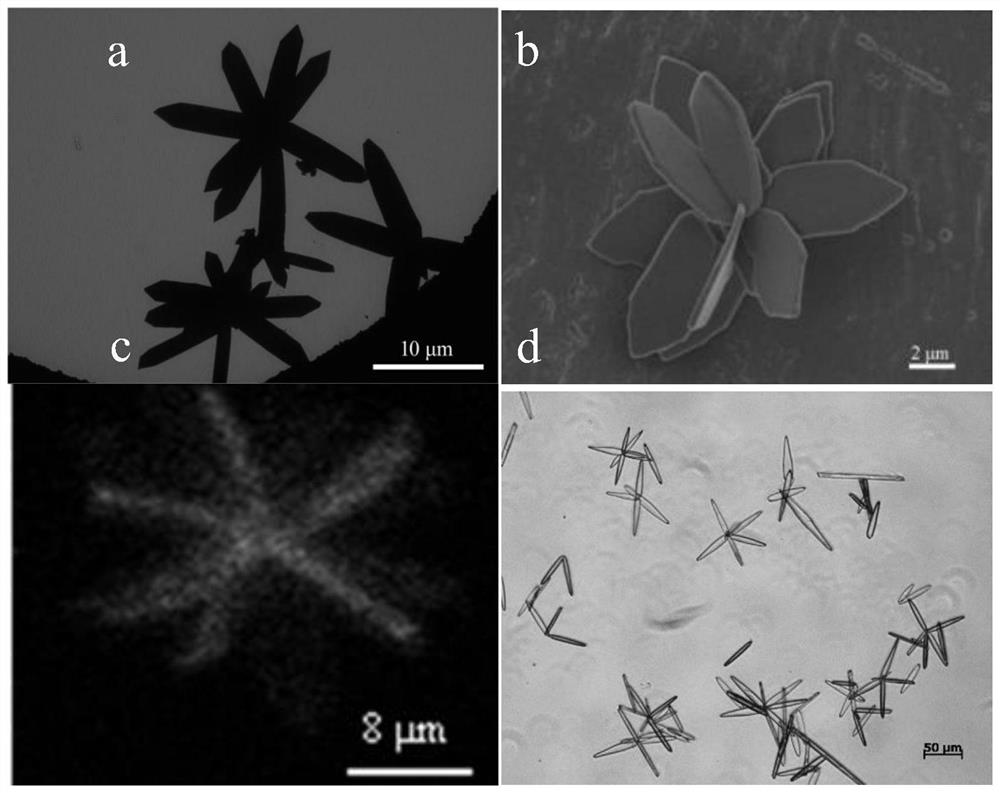

[0077] (2) Preparation of fluorescent nanoflowers of copper nanoclusters

[0078] Weigh 5mg of Cu 4 I 4 , add 2mL dimethyl sulfoxide, then add 2mL glycerol, v...

Embodiment 2

[0089] A method for preparing an LED emitting yellow-green light, comprising the following steps:

[0090] Centrifuge and dry the fluorescent nanoflowers of copper nanoclusters prepared in Example 1 into powder, accurately weigh 5 mg of the nanoflower powder, grind them thoroughly with a mortar, and then accurately weigh the amount of high-refractive LED patch silica gel A and glue B respectively. The quality is 5mg and 20mg, and they are mixed evenly according to the mass ratio of 1:4, and the sample powder is mixed evenly with commercial glue, and the mixed mucus about the size of a bean is taken, deposited on a commercially available LED chip, and heated at 60°C Curing in an oven for 3 hours to produce LEDs.

[0091] The present embodiment obtains the LED figure of emitting yellow-green light such as Figure 6 (a) shown. Spectral analysis shows that the color coordinates of the fluorescence emission spectrum obtained under the excitation wavelength of 365 nm for the yello...

Embodiment 3

[0093] A method for preparing an LED emitting sky blue light, comprising the following steps:

[0094] Accurately weigh 5 mg and 10 mg of the copper nanocluster fluorescent nanoflower powder and blue phosphor powder prepared in Example 1, respectively. Grind thoroughly with a mortar, then accurately weigh 5 mg and 20 mg of high-refractive LED patch silica gel A and B respectively, mix them evenly according to the mass ratio of 1:4, mix the sample powder with commercial glue, and take about The size of the mixed slime was deposited on a commercially available LED chip and cured in an oven at 60°C for 3 hours to manufacture LEDs.

[0095] The present embodiment obtains the LED figure that sends sky blue light as follows Figure 6 (b) shown. Spectral analysis shows that the color coordinates of the fluorescent emission spectrum obtained from the sky-blue LED prepared in this embodiment at an excitation wavelength of 365 nm are (0.23, 0.24).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com